A kind of preparation device of small size high specific capacitance capacitor

A technology for preparing devices and capacitors, used in capacitor manufacturing, electrolytic capacitor manufacturing, capacitors, etc., can solve problems such as general automation, complex preparation methods, and general capacitance, and achieve the effect of increasing volume and improving capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

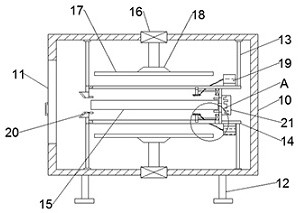

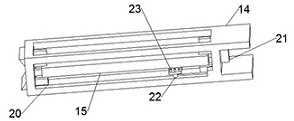

[0017] see Figure 1-3 , a preparation device for a small-sized high specific volume capacitor, comprising a box body 10, a box door 11, a foot 12 and a preparation frame 14; the left and right sides of the bottom of the box body 10 are supported by the foot 12, and the bottom of the foot 12 is fixedly installed with Protective pad, the left side wall middle part of casing 10 is hinged with box door 11, and a side of box door 11 is fixedly equipped with handle, is convenient to the input and output of raw material and product inside casing 10 by box door 11. A group of horizontal preparation racks 14 are arranged inside the box body 10. The upper, lower, left, and right middle parts of the preparation racks 14 are fixedly supported by the support rods 13. The left middle part of the preparation racks 14 is provided with a through hole, and the outside of the through hole is set as a trumpet shape. The structure is convenient for the entry of the ceramic thin film blank 15, and...

Embodiment 2

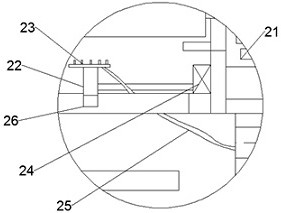

[0021] On the basis of Embodiment 1, a group of cylinders 21 are fixedly installed in the middle part of the right side wall of the preparation frame 14, and a push rod is connected to the left output end of the cylinder 21, and the start cylinder 21 drives the push rod to move left and right, thereby facilitating the preparation Good capacitors push the output to the left.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com