Top pipe work pit supporting method

A working pit and pipe jacking technology, which is applied in excavation, foundation structure engineering, sheet pile wall, etc., can solve the problems of complex underground conditions, narrow working space, unfavorable mechanical pipe jacking equipment and pipe hoisting space requirements, etc., and achieve site geology Good adaptability, reduced construction investment, good support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

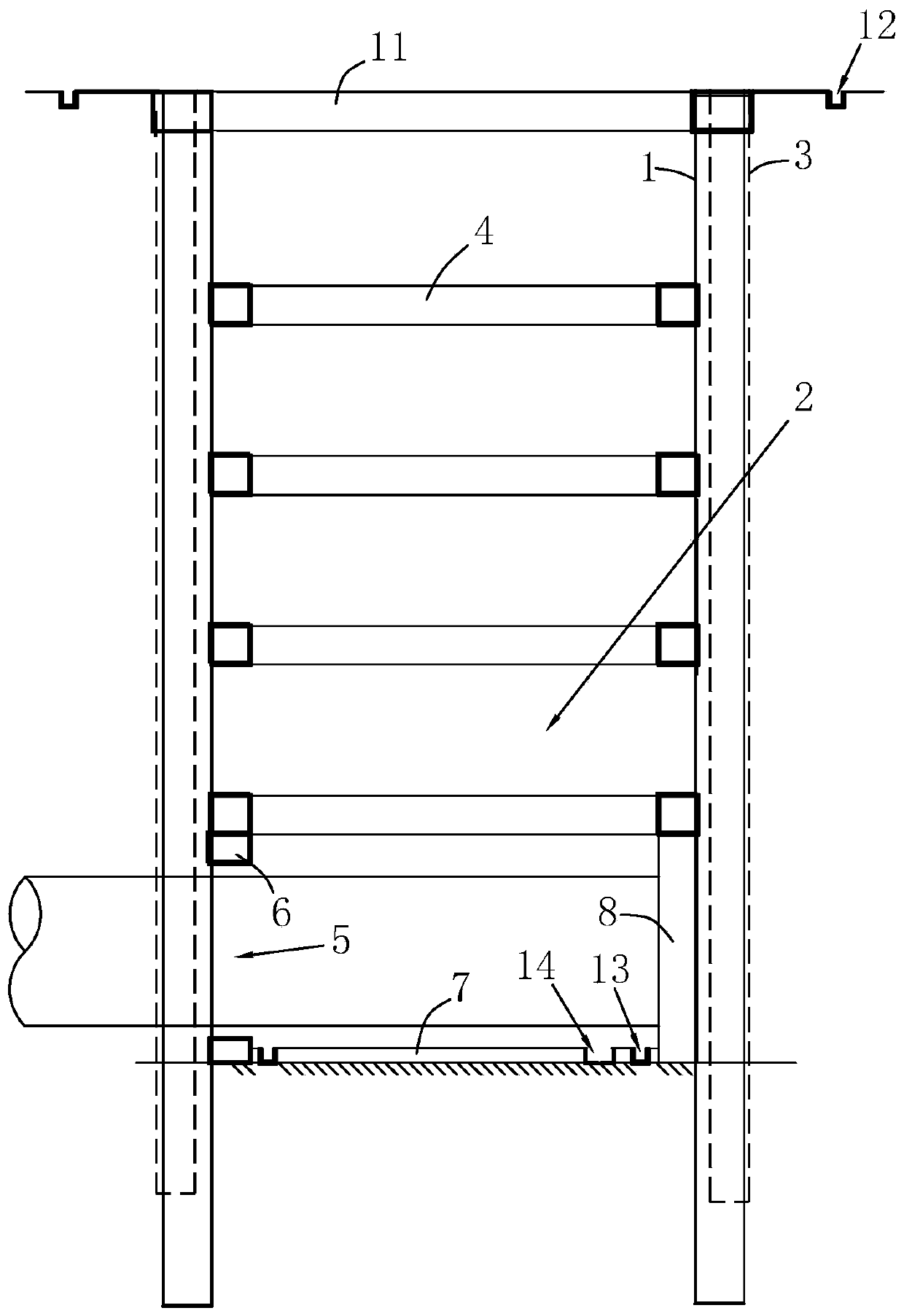

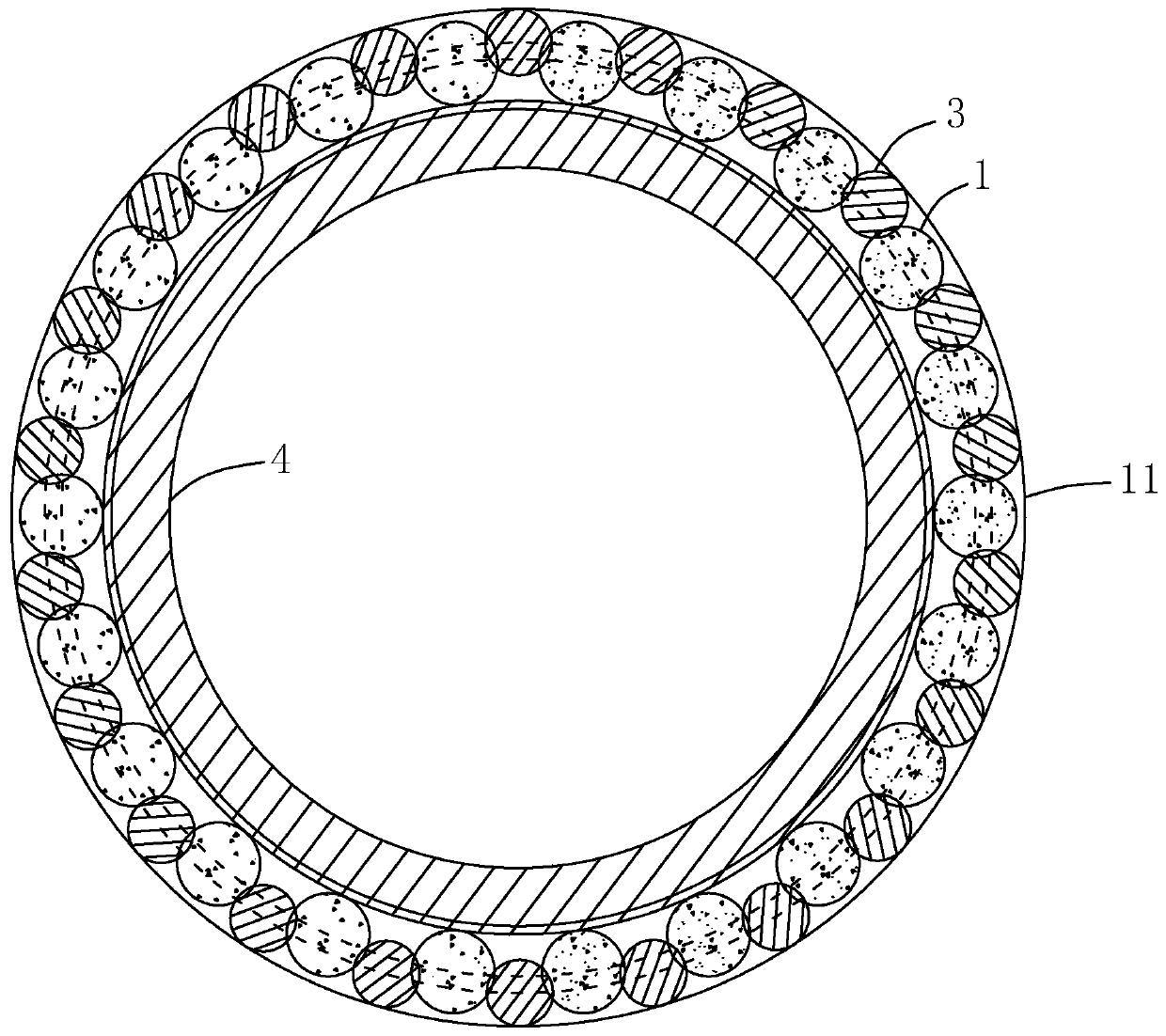

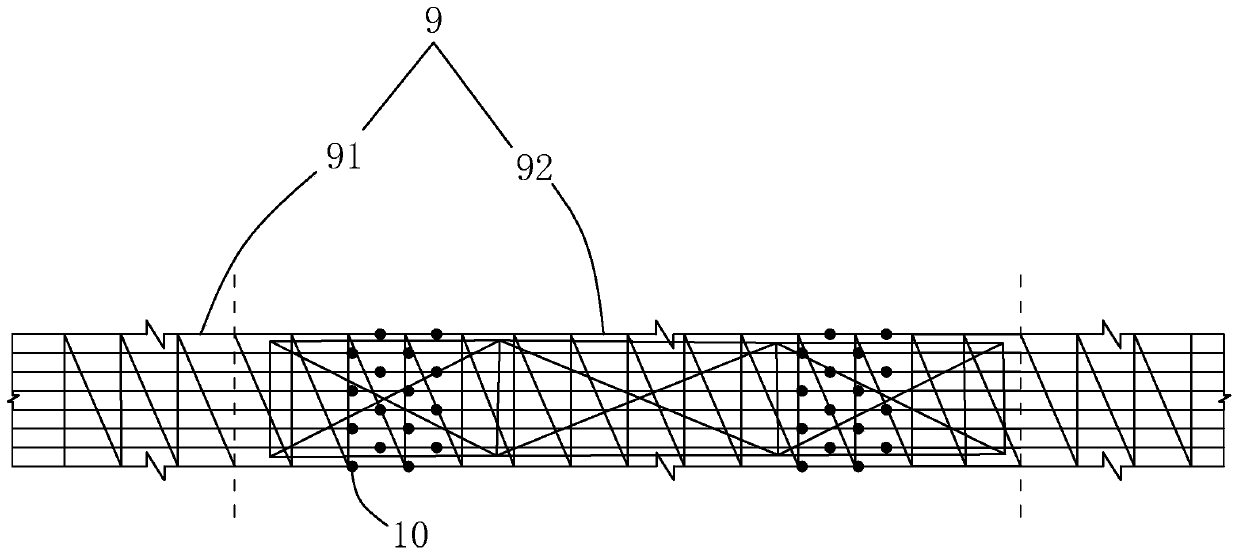

[0038] combine figure 1 with figure 2 , the working pit support structure for pipe jacking construction, including cast-in-situ pile 1, high-pressure jet water-stop pile 3, ring beam 4 and crown beam 11. The cast-in-place pile 1 surrounds the working pit 2 for pile-interval construction to form an annular pile row, and a high-pressure jet water-stop pile 3 is constructed between two adjacent cast-in-place piles 1, and the high-pressure jet water-stop pile 3 is engaged with the cast-in-place pile 1. Form a closed water-stop curtain. Simultaneously, the annular crown beam 11 is poured by formwork at the top of the water-stop curtain. The earth in the working pit 2 is excavated in layers. After the excavation reaches the design elevation of each layer, the construction of the ring beam 4 is carried out through the formwork, and the ring beam 4 is poured together with the water-stop curtain by inserting ribs.

[0039] Such as figure 1 As shown, in the working pit 2, the groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com