Trenchless spigot and socket pipe dismantling method

A socket-and-socket, trenchless technology, applied in the direction of lifting device, hoisting device, etc., can solve the problems that the pipe joint cannot be recycled again, the socket or socket of the pipe joint is damaged, and the construction cost is increased, and the dismantling method is simple and feasible. , The effect of reducing the construction cost and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

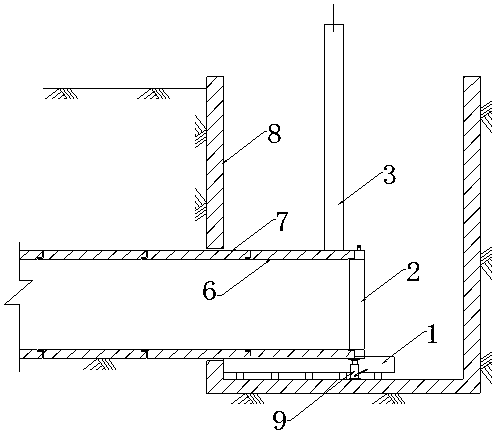

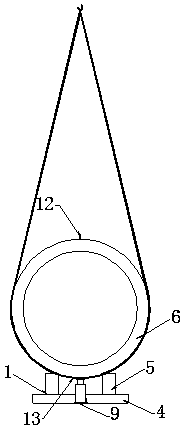

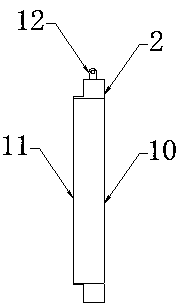

[0021] Such as figure 1 -4 shows:

[0022] A method for dismantling a trenchless socket pipe, the method is based on an auxiliary device installed in a working well for installation and removal of pipe joints, and is implemented in combination with a new dismantling process;

[0023] The above-mentioned auxiliary device includes a pipe jacking track 1 arranged at the bottom of the working well, a hoisting assembly 2 and a flexible sling 3; wherein the pipe jacking track 1 is composed of longitudinal sleepers 4 laid flat on the bottom of the working well and two longitudinal sleepers laid on the longitudinal sleepers. Composed of horizontal crossties 5, longitudinal crossties 4 and transverse crossties 5 are in a vertical relationship, and the span between the two horizontal crossties is not greater than 1 / 2 of the diameter of the pipe joint 6, when the pipe joint 6 is placed on the pipe jacking track 1 The two horizontal horizontal crossties 5 play the role of support and lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com