Hydrophobic oil-resistant food packaging paper and preparation method thereof

A food packaging paper and food packaging technology, applied in the field of papermaking, can solve the problems of reduced physical strength, food hazards, environmental sanitation and environmental safety, etc., and achieve the effects of improving the bonding force between fibers, improving physical properties, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

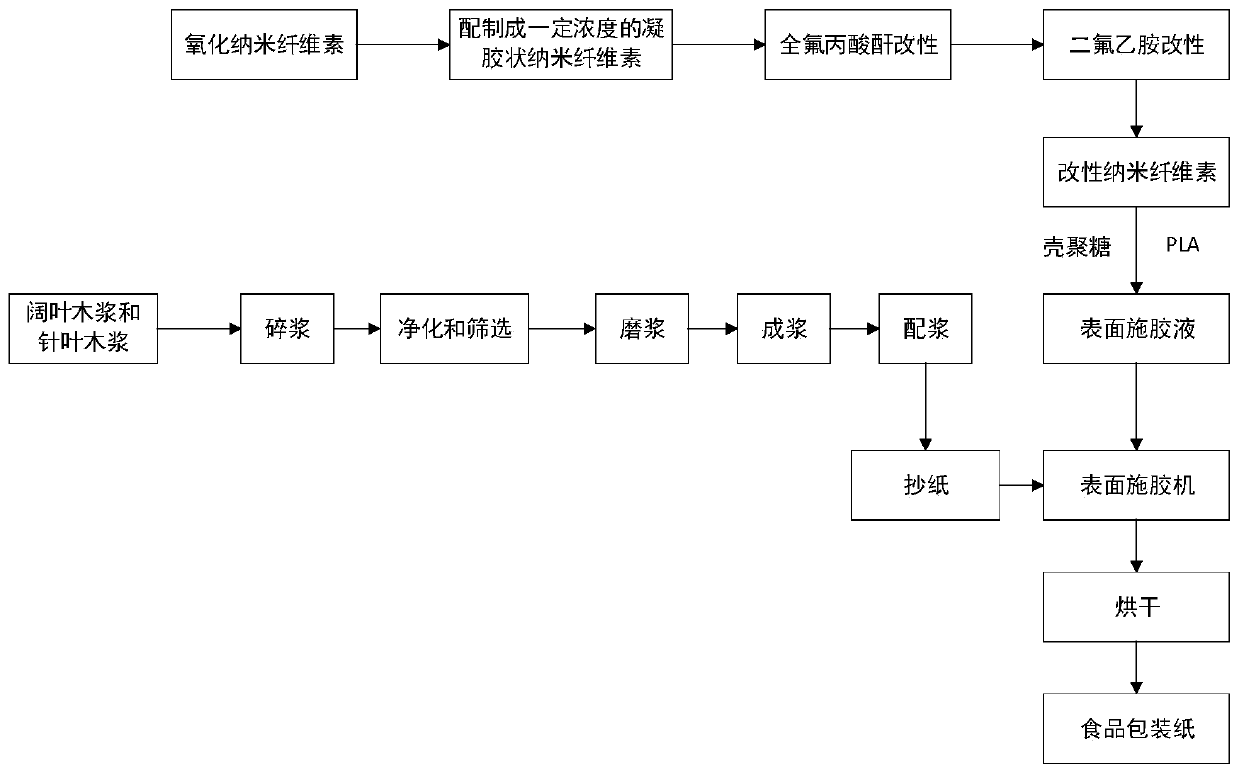

Method used

Image

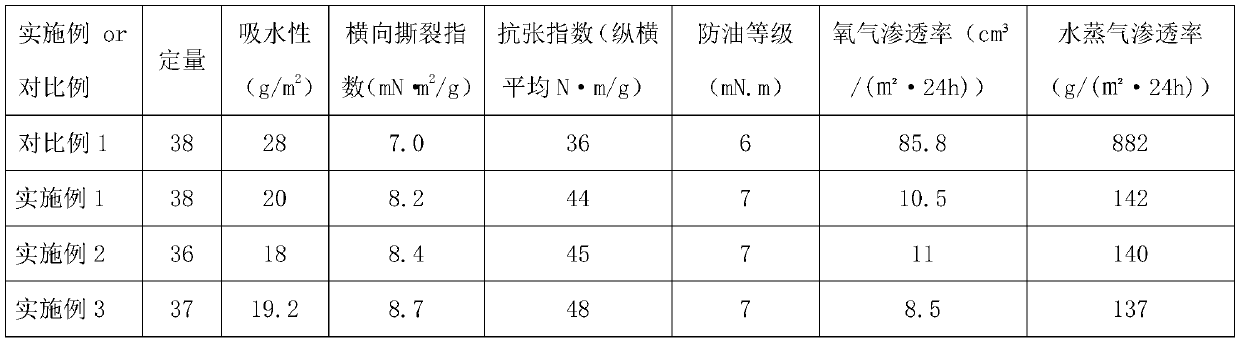

Examples

Embodiment 1

[0037] A kind of preparation method of hydrophobic and oil-resistant food wrapping paper of the present embodiment, described method specifically comprises the following steps:

[0038] (1) First, add water to the purchased nanocellulose (made by TEMPO oxidation-mechanical treatment of softwood pulp fibers) to prepare a 1.5% nanocellulose suspension, and put 1.5% nanocellulose in the reactor The aqueous suspension was evaporated so that the suspension became gel-like. Add dispersant N-N-dimethylformamide and gelatinous nanocellulose into another reactor according to the ratio, mix well, then keep stirring at constant temperature in the reactor for 6 hours at 85°C, then add trifluoroacetic acid anhydride and 4-dimethylaminopyridine (the mass ratio of nanocellulose, trifluoroacetic anhydride, and 4-dimethylaminopyridine is 1:50:2.0), then disperse for 20 minutes, and raise the temperature to 100°C. After 6 hours of reaction Cool for 30 minutes, and then wash with ethanol, aceto...

Embodiment 2

[0048] A kind of preparation method of hydrophobic and oil-resistant food wrapping paper of the present embodiment, described method specifically comprises the following steps:

[0049] (1) First, add water to the purchased nanocellulose (made by TEMPO oxidation-mechanical treatment of softwood pulp fibers) to prepare a 1% nanocellulose suspension, and put 1% nanocellulose in the reactor The aqueous suspension was evaporated so that the suspension became gel-like. Add dispersant N-N-dimethylformamide and gelatinous nanocellulose into another reactor according to the ratio, mix well, then keep stirring in the reactor at constant temperature for 3 hours at 90°C, and then add trifluoroacetic acid anhydride and 4-dimethylaminopyridine (the mass ratio of nanocellulose, trifluoroacetic anhydride, and 4-dimethylaminopyridine is 1:50:1.0), then disperse for 15 minutes, and raise the temperature to 100°C, and react for 5 hours Cool for 30 minutes, and then wash with ethanol, acetone a...

Embodiment 3

[0059] A kind of preparation method of hydrophobic and oil-resistant food wrapping paper of the present embodiment, described method specifically comprises the following steps:

[0060] (1) First, add water to the purchased nanocellulose (made by TEMPO oxidation-mechanical treatment of softwood pulp fibers) to prepare a 1.2% nanocellulose suspension, and 1.2% nanocellulose in the reactor The aqueous suspension was evaporated so that the suspension became gel-like. Add dispersant N-N-dimethylformamide and gelatinous nanocellulose into another reactor according to the ratio, mix well, then keep stirring in the reactor at constant temperature for 4 hours at 90°C, and then add trifluoroacetic acid anhydride and 4-dimethylaminopyridine (the mass ratio of nanocellulose, trifluoroacetic anhydride, and 4-dimethylaminopyridine is 1:50:0.5), then disperse for 10 minutes, and raise the temperature to 100°C, and react for 3 hours Cool for 30 minutes, and then wash with ethanol, acetone a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com