Method for optimizing soybean oil refining production

A soybean oil and crude oil technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of uneven distribution of solid phase and liquid phase, reduce neutral oil soap content, reduce production cost, etc., and achieve reduction of soapstock discharge amount, reduce the loss of neutral oil, and reduce the effect of refining consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Heat the crude oil in the crude oil storage tank, heat the crude oil to 70-75°C, add phosphoric acid with a concentration of 75%, and the addition amount is 0.1‰, mix it, and then enter the acid delay tank, Carry out 40-60min delayed stirring.

[0045] (2) The acid-treated crude oil is mixed with alkali, and a liquid alkali with a concentration of 15% is added. After mixing, it then enters an alkali delay tank for 30-40 minutes of delayed stirring.

[0046] (3) Alkali neutralizes the processed crude oil, and then heats the neutralized crude oil to 80-85° C. through heat exchange, and then separates in a soap-removing centrifuge.

[0047] (4) The separated saponin enters the saponin tank, and the saponin tank enters the storage tank for storage in the tank area.

[0048] (5) The neutral oil obtained by desoaping and centrifugation in step (3) enters the neutral oil mixer, mixes with the washing water in the oil separation tank, and the reuse washing water addition i...

Embodiment 2

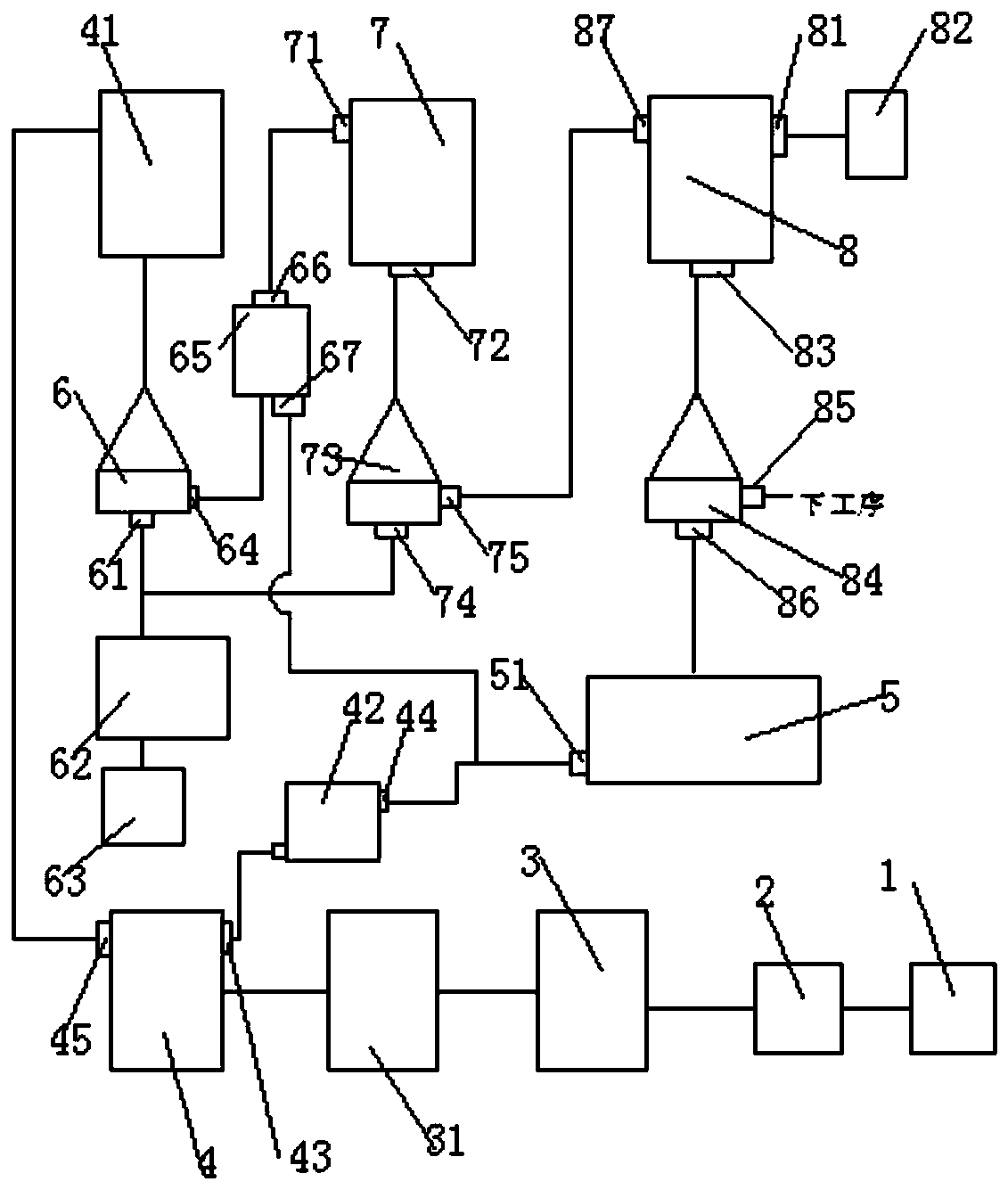

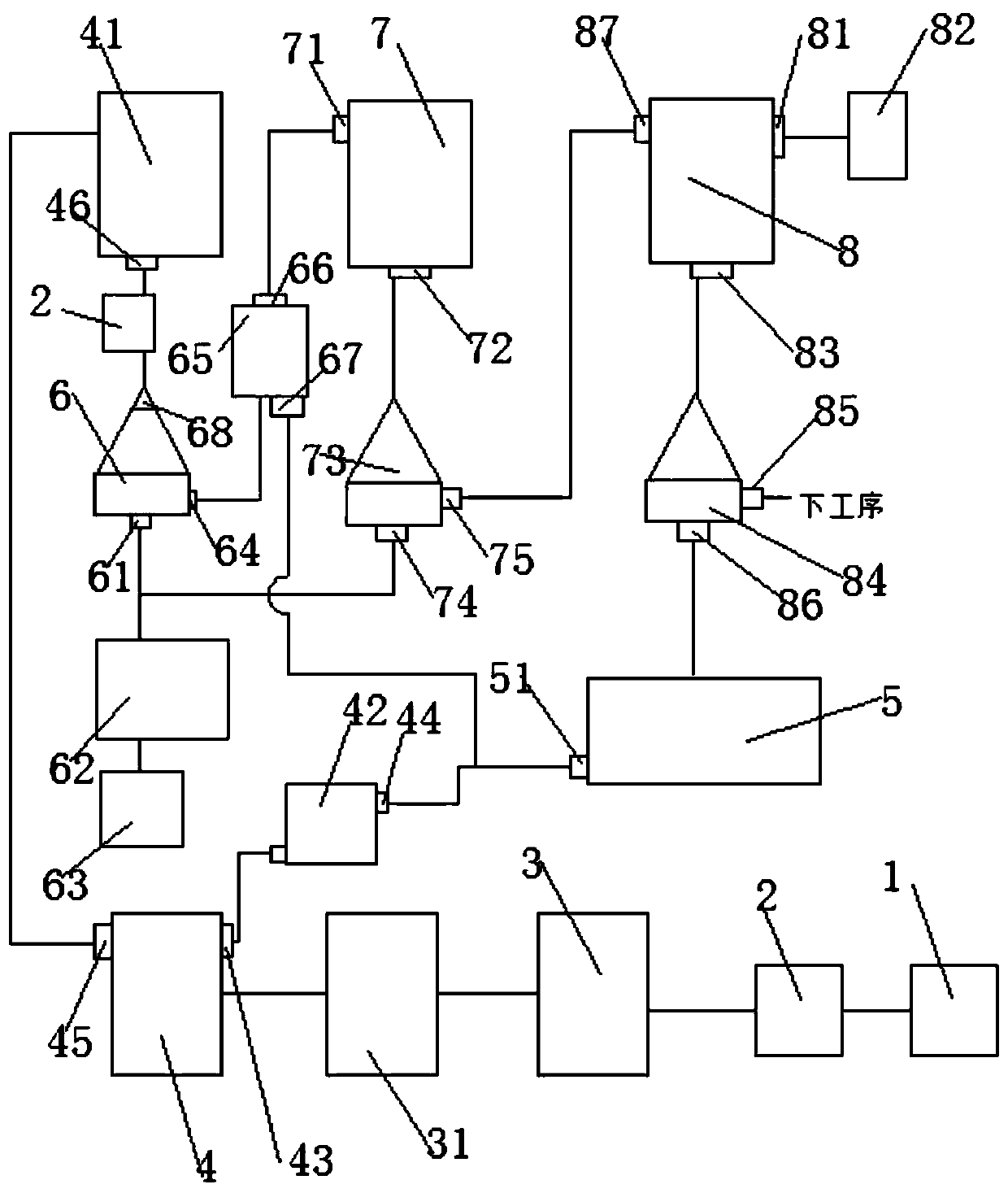

[0055] combine figure 1 , it can be seen that a device for optimizing soybean oil refining production includes a crude oil storage tank 1, a first hydration delay tank 7, and a second hydration delay tank 8, and the crude oil storage tank 1 is connected to a heat exchanger 2. The heat exchanger described above is a plate heat exchanger with good heat exchange effect, simple structure and easy to use.

[0056] Heat exchanger 2 connects acid mixer 3, and acid mixer 3 connects acid delay tank 31, and acid delay tank 31 connects alkali mixer 4, and the material outlet 45 of this alkali mixer connects alkali delay tank 41, and the alkali mixing The soda water inlet 43 of device connects alkali reaction tank 42, and alkali reaction tank water inlet 44 connects the water outlet 51 of sub-oil tank 5; Angle tank 62, the saponin tank 62 is connected to the storage tank 63, the oil outlet 64 of the desoaping centrifuge is connected to the neutral oil mixer 65, and the material outlet 66...

Embodiment 3

[0060] In conjunction with the device of Example 2, a method for optimizing soybean oil refining production of the present invention can be specifically as follows, and the detailed steps are as follows:

[0061] (1) Pass the crude oil in the crude oil storage tank into the heat exchanger, heat the crude oil to 70-75°C, add phosphoric acid with a concentration of 80%, and the addition amount is 0.09‰, enter the acid mixer for mixing, and then Enter the acid delay tank for 40-60min delayed stirring.

[0062] (2) The crude oil after the acid treatment comes out from the acid delay tank and enters the alkali mixer, while adding a concentration of 15% liquid caustic soda in the alkali mixer, after the alkali mixer mixes, then enters the alkali delay tank, Enter 30-40min delayed stirring.

[0063] (3) Alkali neutralizes the processed crude oil, then heats the neutralized crude oil to 80-85°C through a heat exchanger, and enters the soap-removing centrifuge for separation.

[0064...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com