Corn oil/methanol/PODE mixed fuel suitable for diesel engine

A mixed fuel, 35% PODE35% technology, applied in the field of new mixed fuel, can solve the problem of limited mixed fuel containing PODE, and achieve the effect of reducing environmental pressure, reducing emissions, and reducing the pressure of rapid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the above-mentioned fuel of the present invention comprises the following steps: measure each component according to the volume ratio, first add methanol into corn oil to form an incomplete miscible mixed solution, then add a certain volume of PODE into the mixed solution under stirring and mix evenly , so that it can be dissolved to obtain a blended fuel. The mixing temperature is preferably between 35°C and 45°C.

[0024] By calculating the kinematic viscosity of the novel mixed fuel containing methanol provided by the present invention is 2.24-4.44mm 2 / s, meeting the fuel viscosity range suitable for traditional diesel engines. The novel mixed fuel provided by the invention, corn oil / methanol / PODE has good mutual solubility, and the obtained mixed fuel can be stored at 40 degrees centigrade for a long time without delamination.

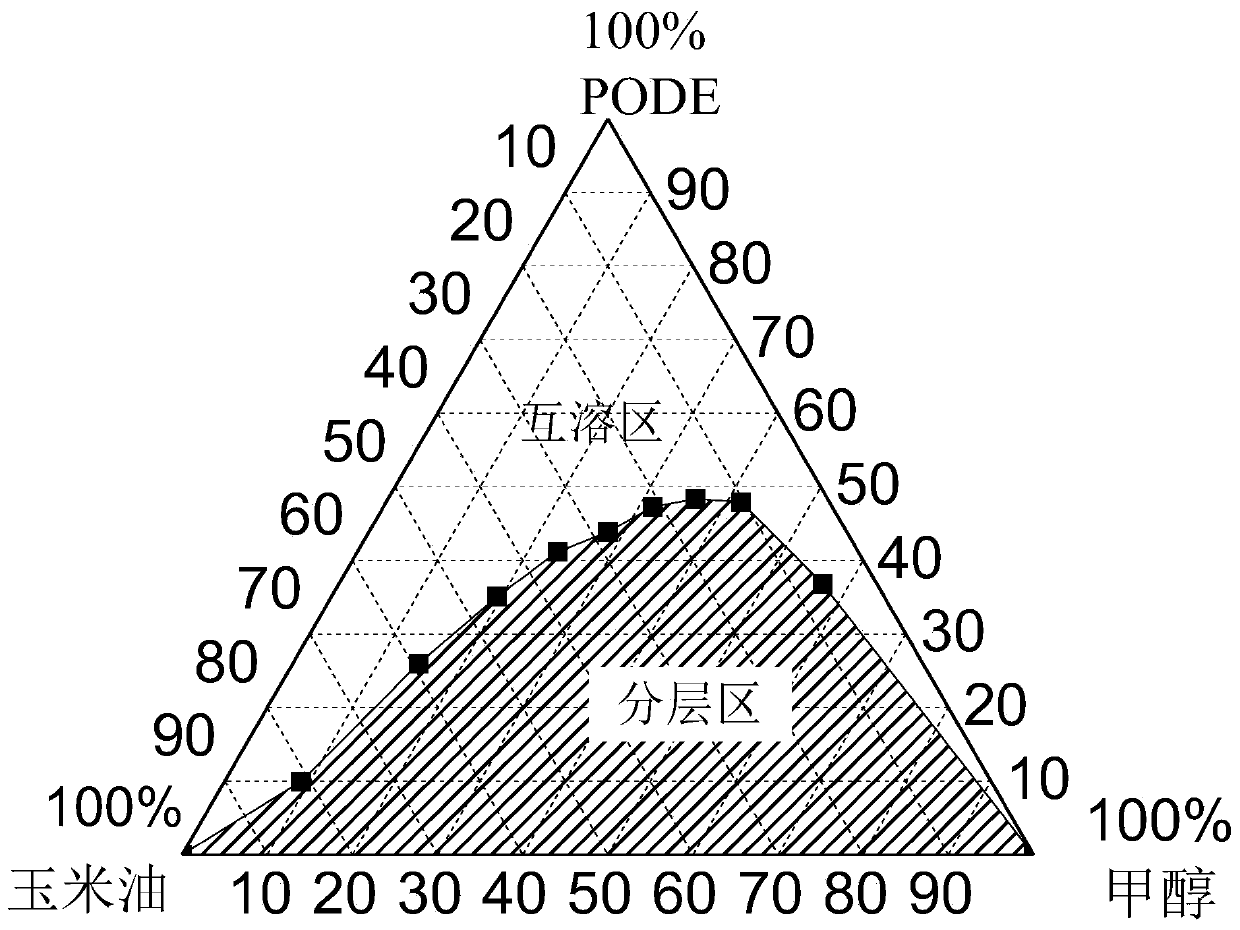

[0025] At 40°C, when the blending ratio of methanol is between 10% and 90%, the miscibility of corn oil and me...

Embodiment 1

[0028] Methanol 15L, corn oil 17.5L, PODE 17.5L.

[0029] The corn oil is a commercial grade (GB / T 19111-2017) corn oil. The mass percent concentration of methanol is 99.5%. The PODE is a mixture of PODE3-6.

[0030] Configuration method: first add methanol to corn oil to form an incomplete miscible mixture, then add PODE to the mixture under stirring and mix evenly to obtain a blended fuel. The mixing temperature is 40°C.

[0031] Tested: kinematic viscosity is 4.35mm 2 / s, to meet the requirements of diesel engines.

Embodiment 2

[0033] Methanol 20L, corn oil 10L, PODE 20L.

[0034] The corn oil is a commercial grade (GB / T 19111-2017) corn oil. The mass percent concentration of methanol is 99.8%. The PODE is a mixture of PODE3-6.

[0035] The configuration method is the same as in embodiment 1

[0036] Tested: kinematic viscosity is 2.94mm 2 / s, to meet the requirements of diesel engines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com