Laser-weldable modified polypropylene material and preparation method thereof

A polypropylene material and laser welding technology, which is applied in the field of laser welding, can solve the problems of poor near-infrared light permeability and other problems, achieve the effect of breaking through performance bottlenecks, improving permeability, and broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

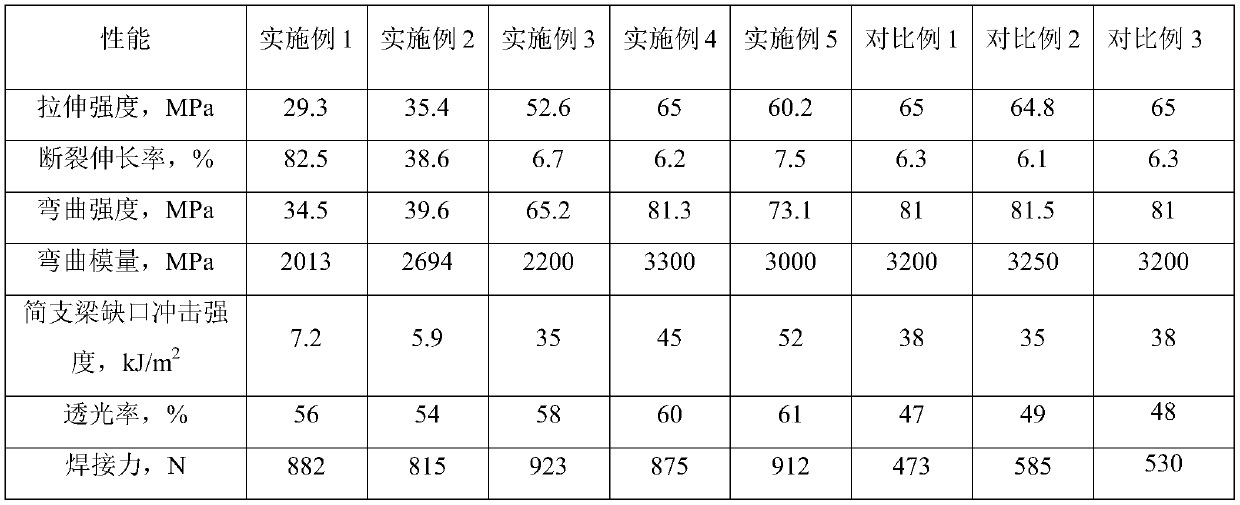

Examples

Embodiment 1

[0028] The raw materials of this embodiment are: in parts by weight, 83.4 parts of copolymerized polypropylene, 15 parts of mica powder, 0.3 parts of nano silicon dioxide, 0.3 parts of hindered phenolic antioxidants, 0.3 parts of phosphite antioxidants, 0.3 parts of hindered amines 0.4 parts of light stabilizer, 0.3 parts of perylene-based black toner.

[0029] The above-mentioned raw materials were put into a high-speed mixer and mixed, the mixing speed was 600 rpm, and the mixing time was 2 minutes.

[0030] The above-mentioned mixed raw materials are fed into a twin-screw extruder, melt-blended, extruded and granulated at a temperature of 200° C. to finally obtain a product.

Embodiment 2

[0032] The raw materials of this embodiment are: in parts by weight, 77.8 parts of copolymerized polypropylene, 20 parts of mica powder, 0.5 parts of nano silicon dioxide, 0.4 parts of hindered phenolic antioxidants, 0.4 parts of phosphite antioxidants, 0.4 parts of hindered amines 0.5 part of light stabilizer, 0.4 part of perylene-based black toner.

[0033] The above-mentioned raw materials were put into a high-speed mixer and mixed, the mixing speed was 600 rpm, and the mixing time was 2 minutes.

[0034] The above-mentioned mixed raw materials are fed into a twin-screw extruder, melt-blended, extruded and granulated at a temperature of 200° C. to finally obtain a product.

Embodiment 3

[0036] The raw materials of this embodiment are: in parts by weight, 88.9 parts of polypropylene copolymer, 10 parts of glass fiber, 0.2 part of nano-calcium carbonate, 0.2 part of hindered phenolic antioxidant, 0.2 part of phosphite antioxidant, 0.2 part of hindered amine light 0.3 parts of stabilizer, 0.3 parts of perylene-based black toner.

[0037] The above-mentioned raw materials were put into a high-speed mixer and mixed, the mixing speed was 600 rpm, and the mixing time was 2 minutes.

[0038] The above-mentioned mixed raw materials are fed into a twin-screw extruder, melt-blended at a temperature of 220° C., extruded and granulated, and finally a product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com