Mechanical arm jig for stably grabbing and assembling pearl wool housing for packaging

A technology for packaging and pearl cotton, which is applied in the direction of packaging, etc., can solve the problems of large overall deformation of the finished pearl cotton shell, difficulty in grasping the pearl cotton shell stably, and large tolerances in appearance dimensions, etc., so as to reduce labor costs and labor costs. Effects on labor intensity, improved packaging quality, improved handling and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

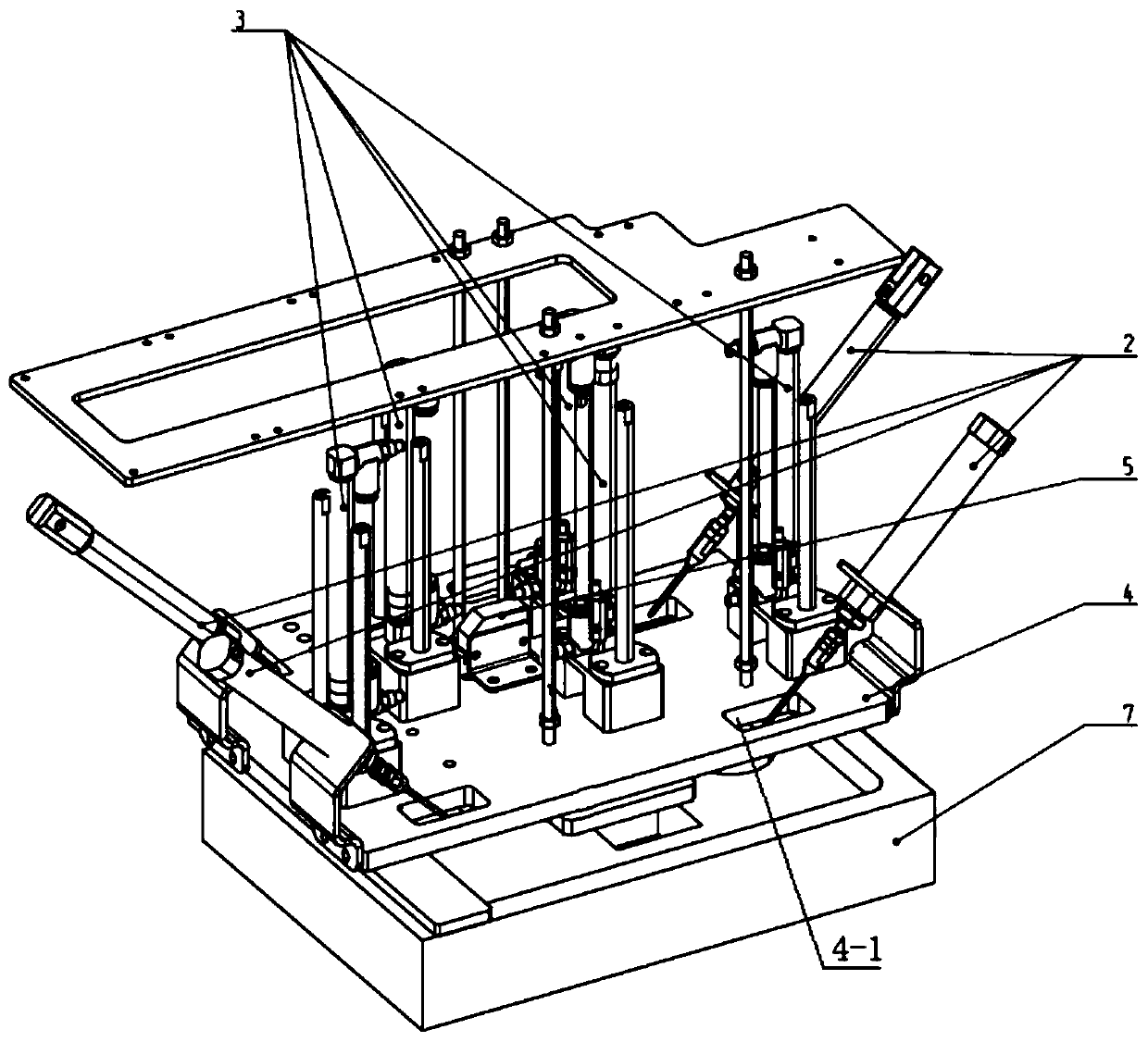

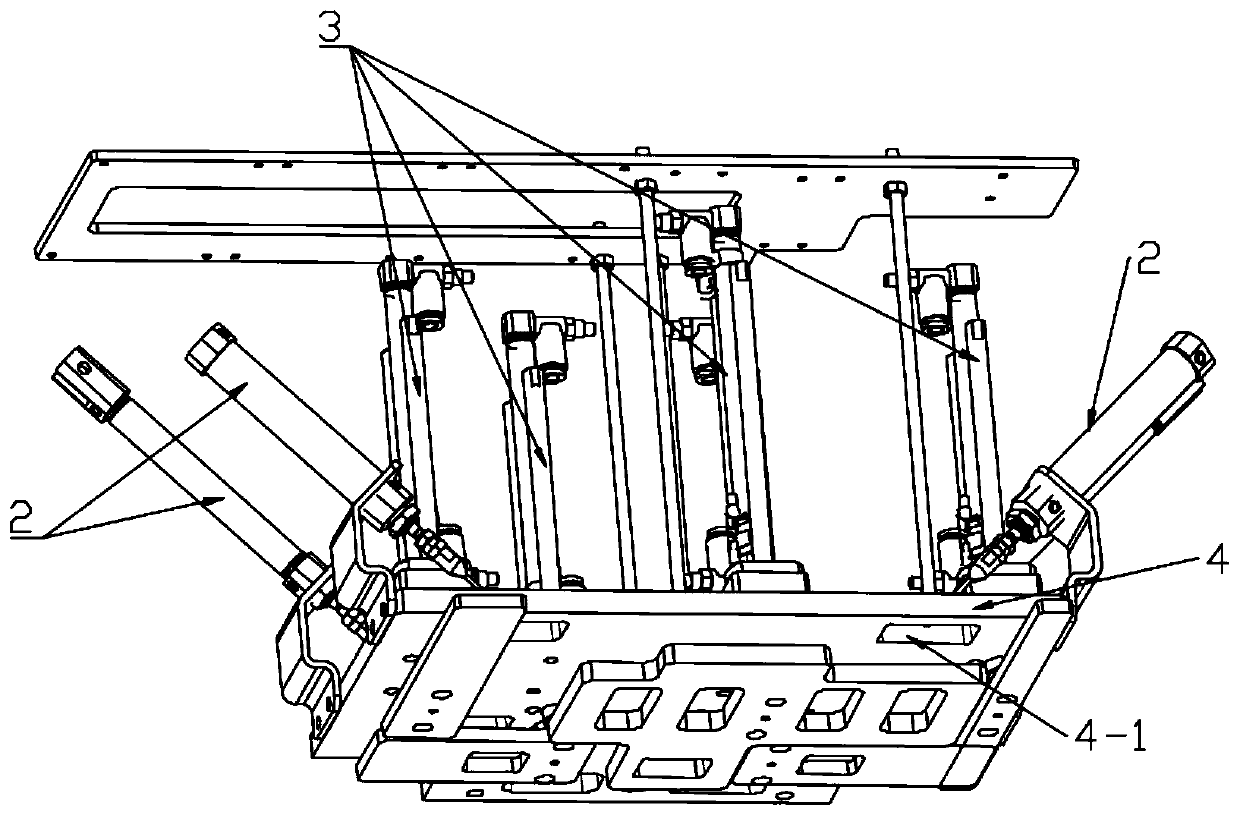

[0025] Such as figure 1 , 2 , 5, and 6, the manipulator tool for stably grasping and assembling the pearl cotton shell for packaging includes a linear module 1, a grasping mechanism 2, a fixed plate 4, a screw nut lifting mechanism 6, and a mounting plate 7 , the mounting plate 7 is fixedly mounted on the slider of the linear module 1, the lead screw nut lifting mechanism 6 is fixedly mounted on the mounting plate 7, the fixed plate 4 is fixedly mounted on the lead screw nut lifting mechanism 6, the fixed plate 4 One pair of corresponding grasping mechanisms 2 are installed on a group of opposite sides. When the linear module 1 works, it can drive the screw nut lifting mechanism 6 to move left and right on the linear module 1 through the mounting plate 7, so that the grabbing mechanism 2 that grabs the pearl cotton shell can be driven by the screw nut lifting mechanism 6 to move along the linear module. The group moves, and the pearl cotton shell is transported from the grab...

Embodiment 2

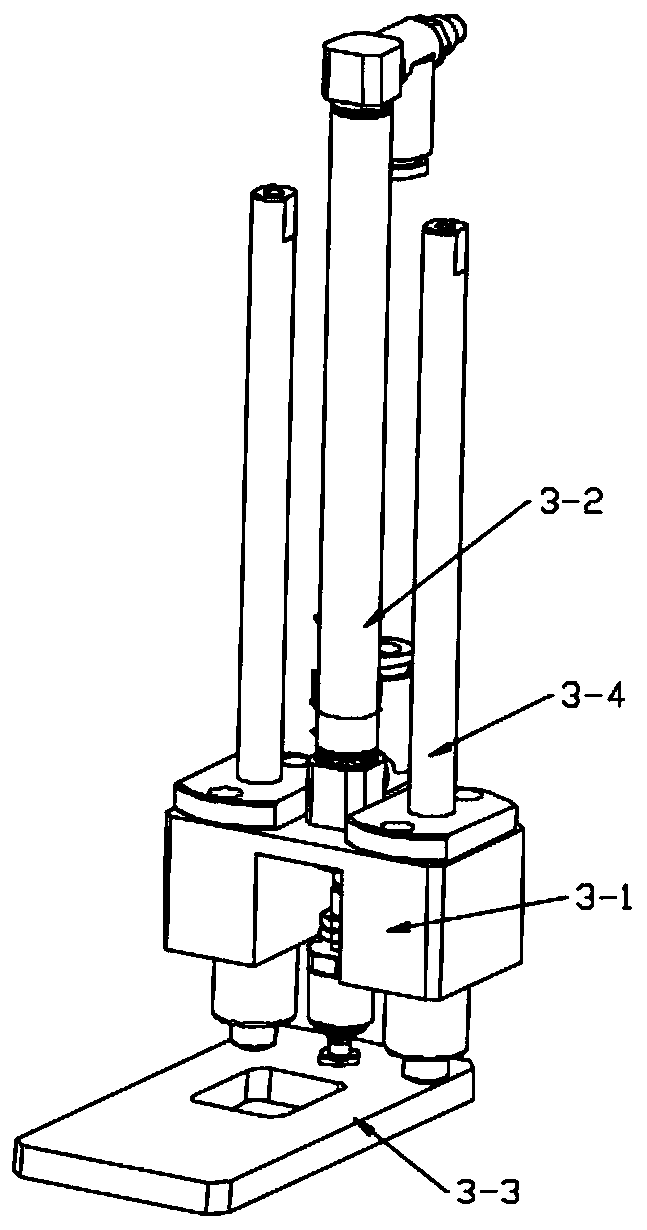

[0030] On the basis of Embodiment 1, 2-4 press-fitting mechanisms 3 are installed on the fixed plate 4, such as image 3As shown, the press-fit mechanism 3 includes a fixed seat 3-1, a press-fit cylinder 3-2, and a press-fit plate 3-3, and the described fix seat 3-1 is fixedly mounted on the fixed plate 4, and the press-fit cylinder 3-2 is installed on the fixed seat 3-1, and its end is fixedly connected with the press-fit plate 3-3 after the piston rod of the press-fit cylinder 3-2 passes through the fix plate 4. Two guide rods 3-4 are installed on the fixed base 3-1, the guide rods 3-4 are installed on the fixed base 3-1 through linear bearings, and the lower ends of the two guide rods 3-4 are fixed on the press-fit plate 3-3 up. Before the grasping mechanism 2 grabs the pearl cotton shell, the press-fit cylinder 3-2 works first, and the press-fit plate 3-3 is pushed out and pressed on the pearl cotton shell through its piston rod, and the press-fit plate 3-3 is close to th...

Embodiment 3

[0034] On the basis of Embodiments 1 and 2, a photoelectric switch 5 is installed on the fixed plate 4, and the photoelectric switch (5) is connected to PLC6, and PLC6 is connected to the solenoid valve of press-fit cylinder 3-2 and grabbing cylinder 2-2 The solenoid valve is connected, wherein, the press-fit cylinder 3-2 is a double-coil solenoid valve; the motor 6-5 is connected to PLC6, and the solenoid valve of grabbing cylinder 2-2 is connected to PLC6; the circuit control schematic diagram is as follows Figure 7 shown.

[0035] When the lead screw nut lifting mechanism 6 drives the grasping mechanism 2 and the pressing mechanism 3 installed on the fixed plate 4 to move downward, when the photoelectric switch 5 detects the right pearl cotton shell, the photoelectric switch 5 transmits the signal to the PLC 6 , PLC6 controls the motor 6-5 to stop working, and at the same time, PLC6 controls to start the press-fit cylinder 3-2, and the piston rod of the press-fit cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com