A system and method for predicting and controlling the forming quality of additively manufactured parts

A technology of forming quality and additive manufacturing, applied in additive processing, manufacturing auxiliary devices, processing data acquisition/processing, etc. The effect of improving the quality of manufactured parts and reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

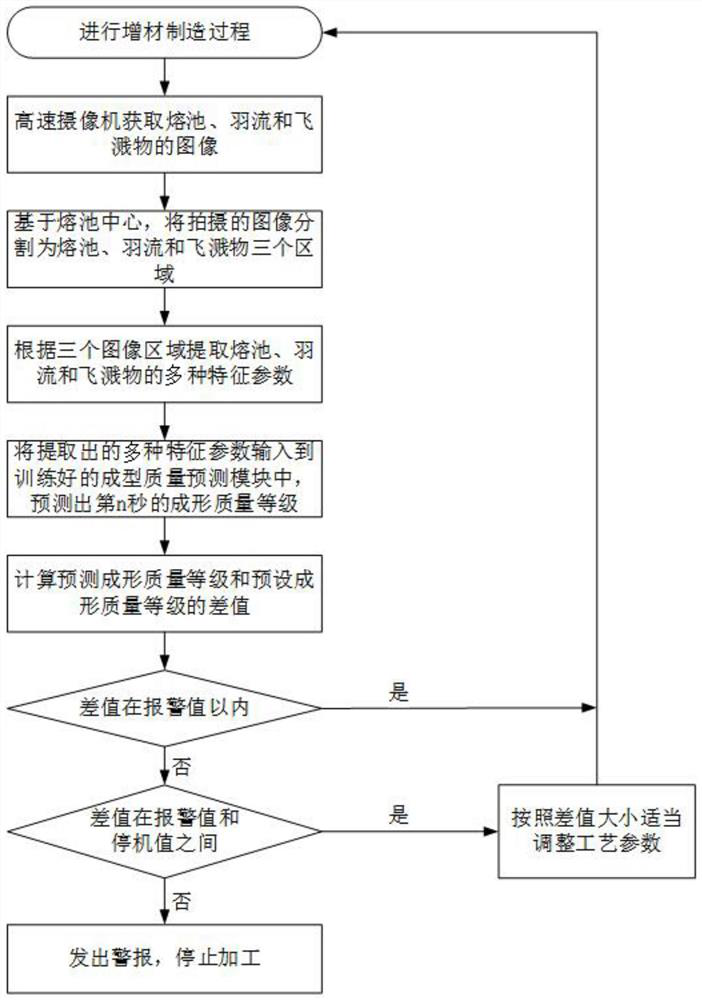

[0029]In order to make the objects, technical solutions, and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

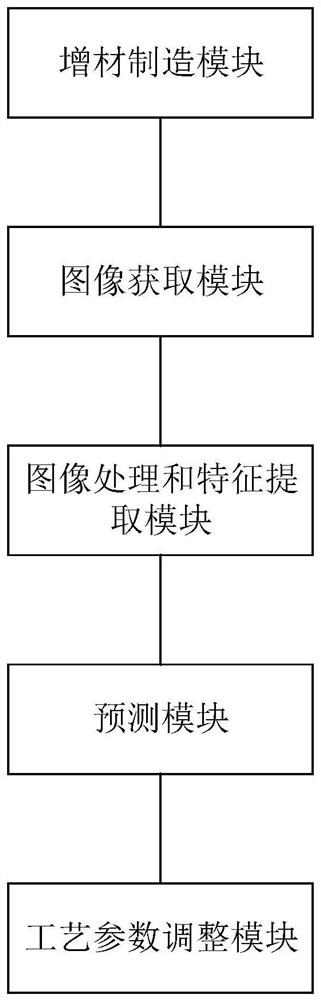

[0030]Referfigure 1 The structure shown is shown.

[0031]An additional material forming mass prediction and control system of the present invention, including a reducing manufacturing module, an image acquisition module, an image processing, and a feature extraction module, a prediction module, and a process parameter adjustment module;

[0032]The additive manufacturing module is manufactured by adding materials according to the preset process parameters.

[0033]The image acquisition module uses a high-speed camera to image the molten pool, a fur and a splash, and the high speed camera is mounted in the addition of the additive manufacturing area.

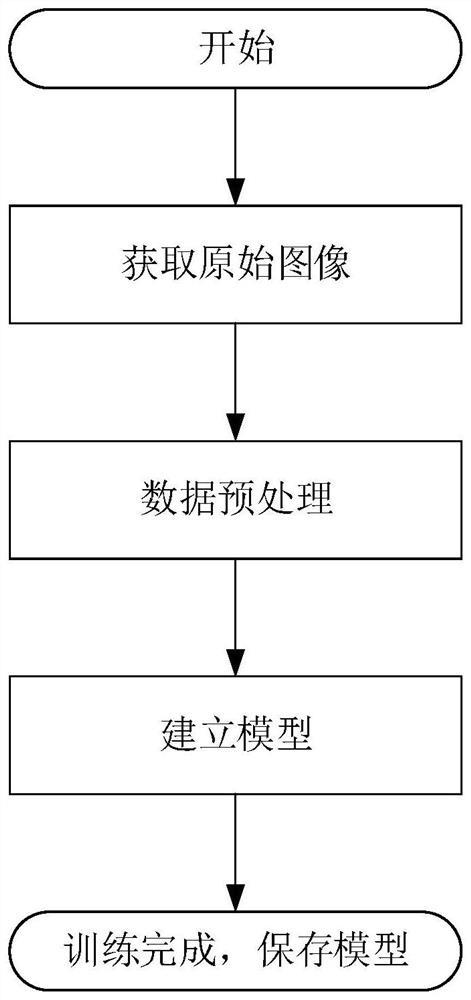

[0034]The image processing and feature extraction module divided the image acquired by the image acquisition module into three regions of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com