Detachable paint brush production technology

A production process and technology of paint brushes, applied in the field of paint brushes, can solve the problems of non-environmental protection, energy saving, waste of handles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

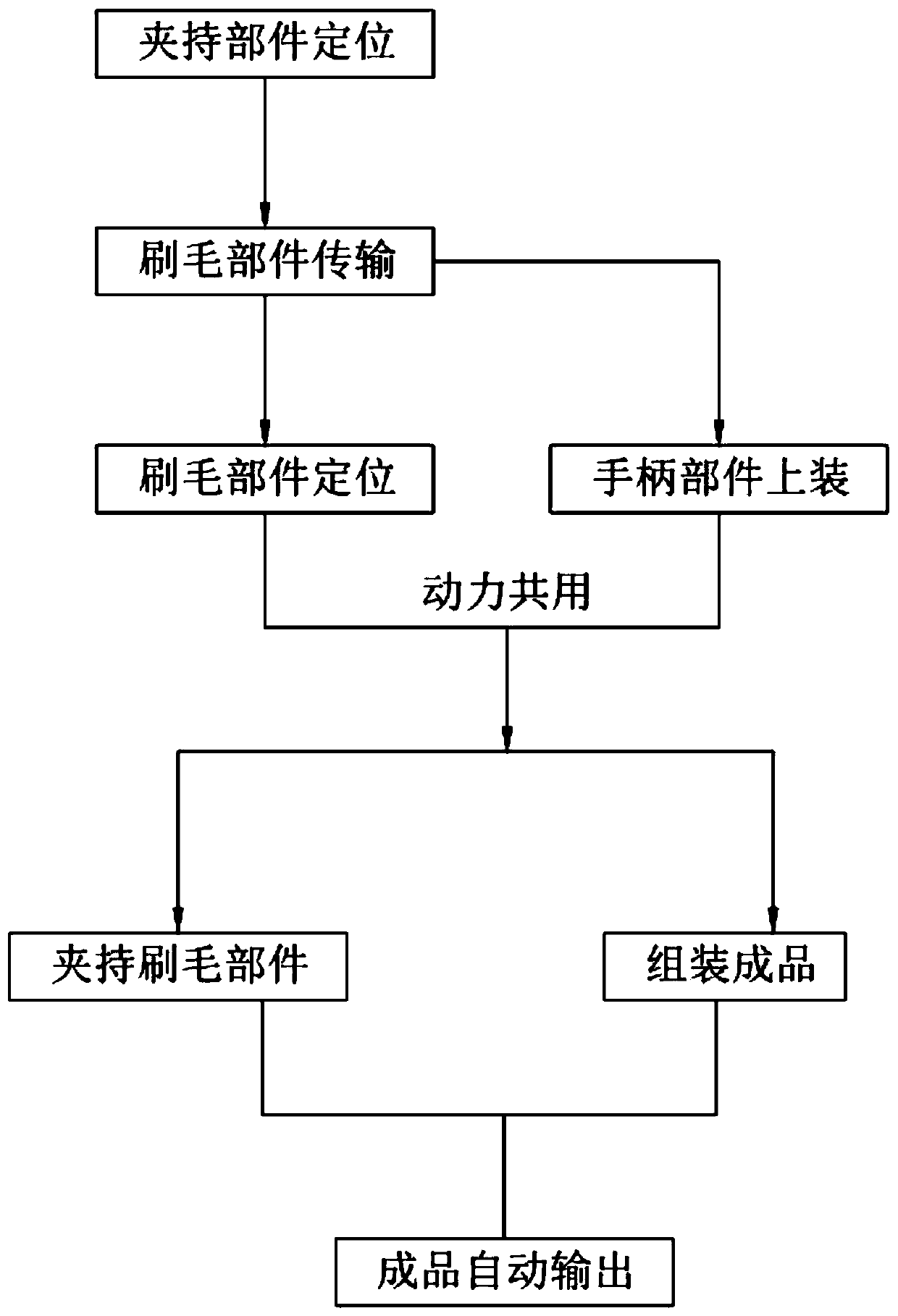

[0093] Such as Figure 16 Shown, a kind of detachable paint brush production process comprises:

[0094] Step 1, positioning the clamping component, manually placing the clamping component 32 on the mounting column 312 of the support assembly 31, and using the mounting column 312 to achieve positioning;

[0095] Step 2, bristle component transmission, one end of the bristle component 13 is located on the first transmission assembly 11 and the other end is suspended outside the first transmission assembly 11, until it is transmitted to the second transmission assembly 12, and suspended outside the first transmission assembly 11 The bristle part 13 is transported on the second transport assembly 12;

[0096] Step 3, position the bristle part, start the extrusion assembly 33, the insertion rod 334 of the extrusion assembly 33 presses down on the lower clamping plate 3221 of the lower clamping part 32 through the socket 335, and the bristle part 13 is transported to the clamping ...

Embodiment 2

[0112] Referring to Embodiment 1, an automatic output device for paint brushes of the present invention is described.

[0113] Such as figure 1 Shown, a kind of automatic output device for paintbrush, comprises:

[0114] The bristle feeding device 1, the bristle feeding device 1 includes a first transmission assembly 11 and a second transmission assembly 12 arranged on one side of the first transmission assembly 11, one end of the bristle component 13 is located on the first transmission assembly 11 And the other end is located on the second transmission component 12;

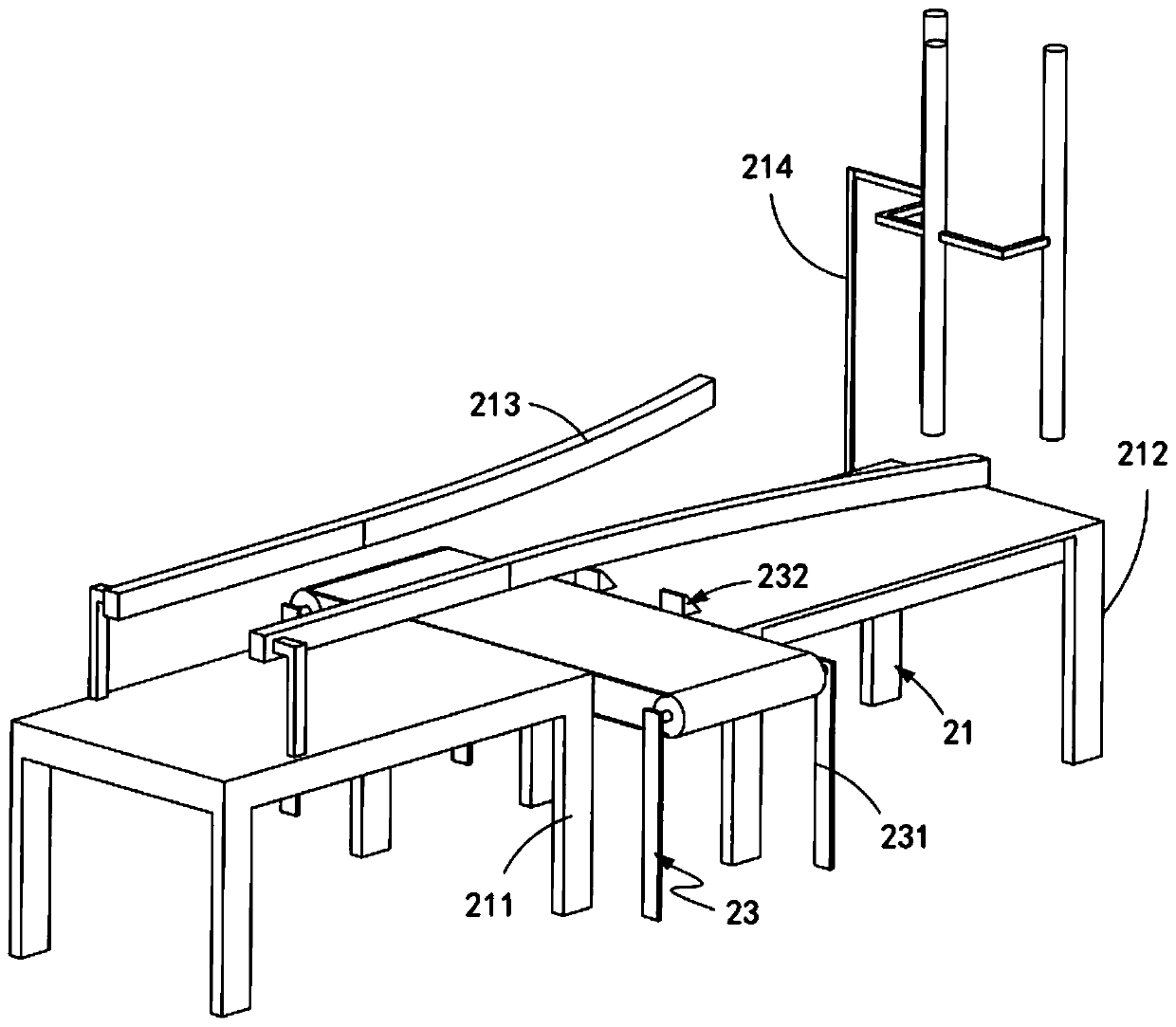

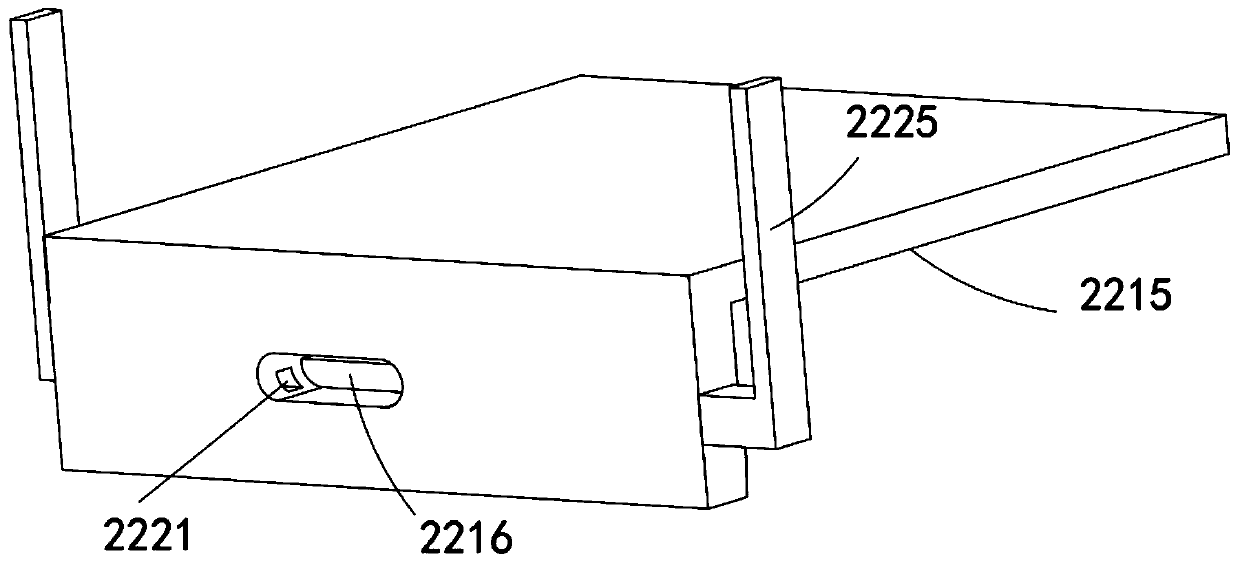

[0115] Handle feeding device 2, said handle feeding device 2 includes a third conveying assembly 21 arranged perpendicularly to the conveying direction of said first conveying assembly 11, and a flat pushing assembly arranged slidably along said conveying direction of said third conveying assembly 21 22 and the feeding assembly 23 arranged vertically with the third conveying assembly 21 and arranged along the...

Embodiment 3

[0169] Such as Figure 15 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment three and embodiment one is:

[0170] further, such as Figure 15 As shown, the transmission assembly 34 includes:

[0171] A transmission rod a341, the transmission rod a341 is fixedly connected to the driving rod 333 and arranged vertically thereto;

[0172] Switching member 342, said switching member 342 includes a rack a3421 fixedly connected with said transmission rod a341 and arranged vertically, a frame e3422 installed on the frame d331, a rotating shaft c3423 rotatably arranged on said frame e3422 , the gear a3424 meshed with the rack a3421 and fixedly arranged with the rotating shaft c3423, the gear b3425 arranged on one side of the ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com