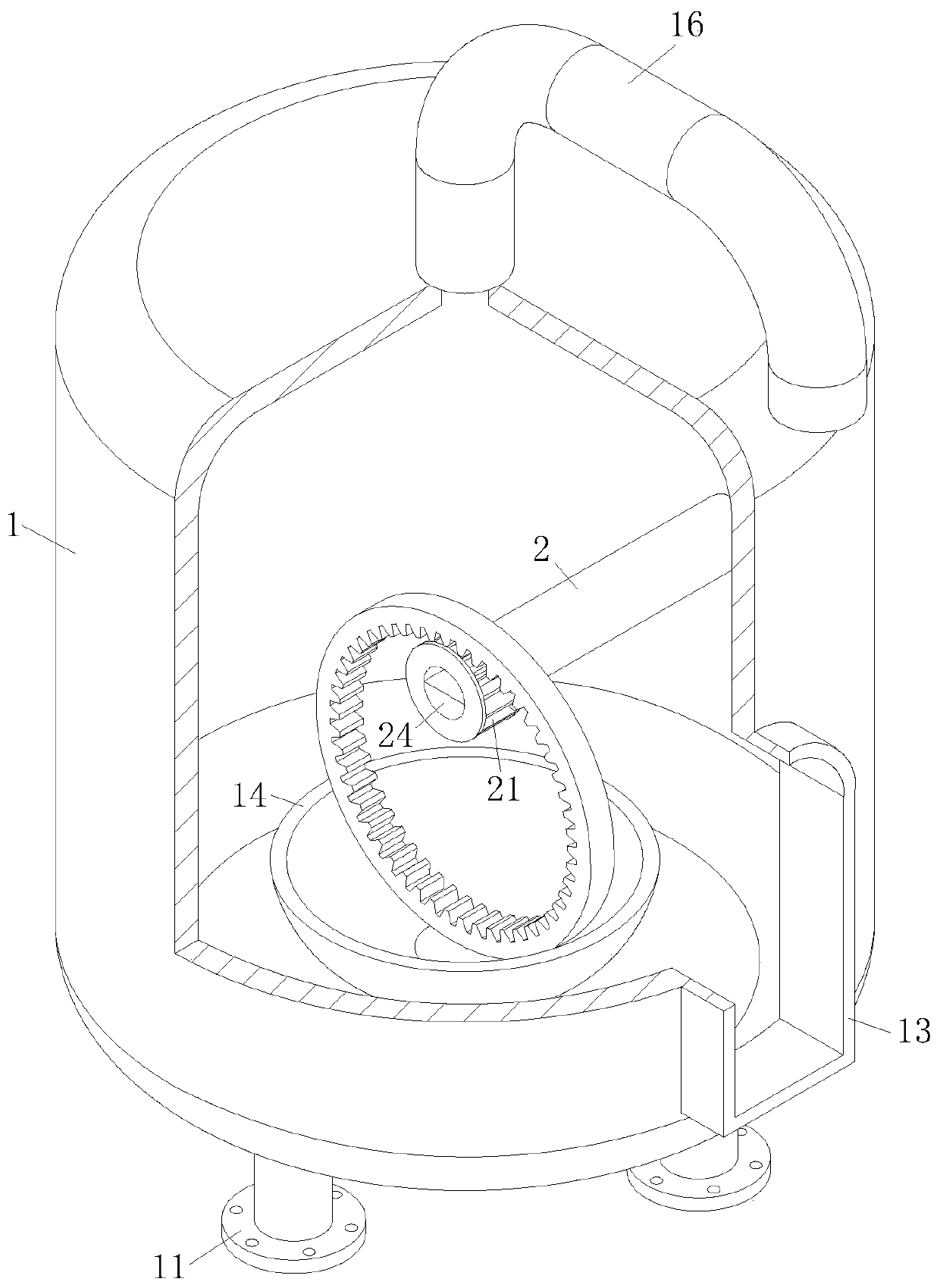

Surface treatment nitridizing furnace

A technology of surface treatment and nitriding furnace, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve problems such as poor meshing, abnormal noise of transmission operation, long nitriding production cycle, etc., and achieve improvement Heating rate, effect of increasing mass and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

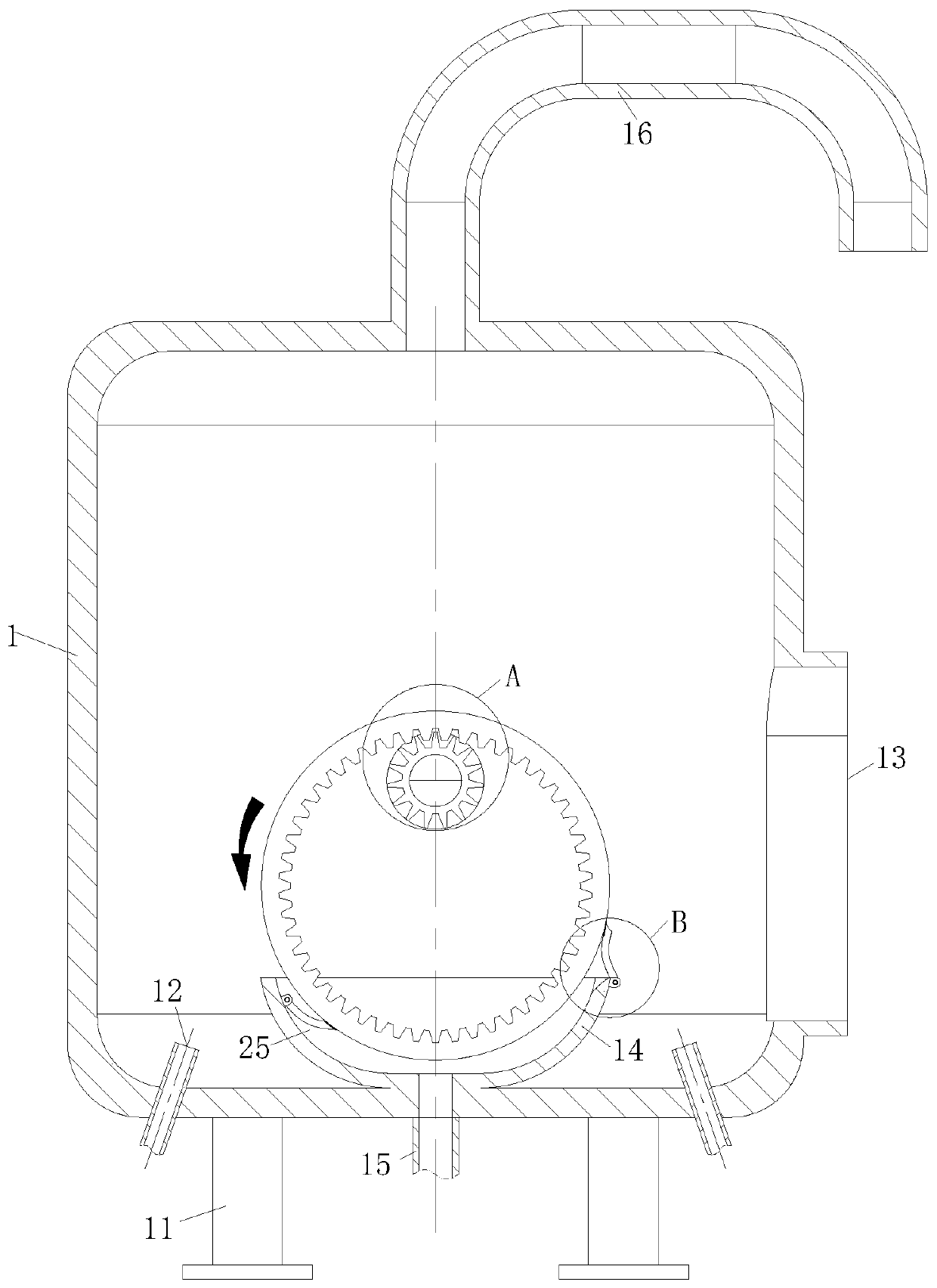

Examples

Embodiment approach

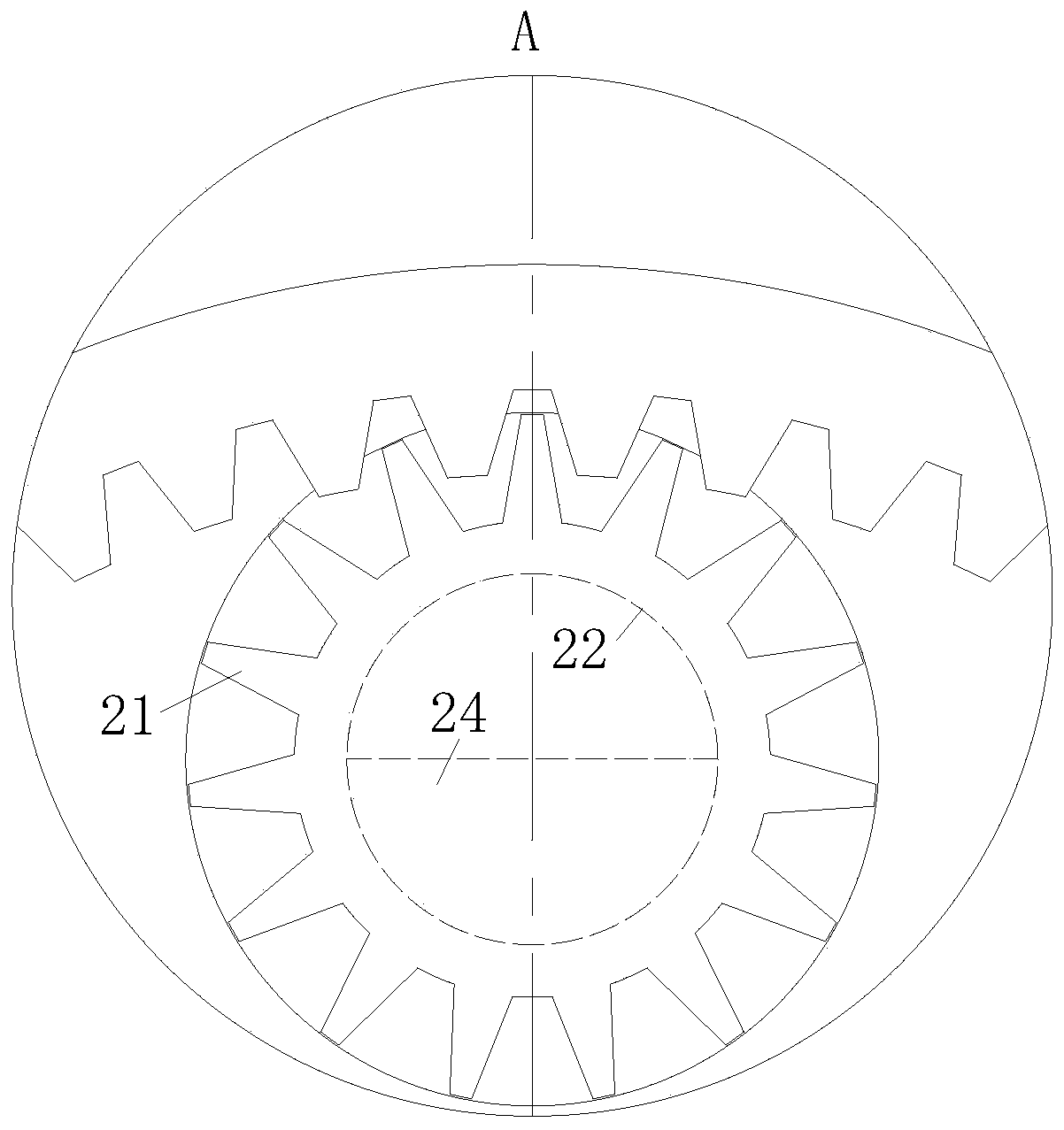

[0032] As an embodiment of the present invention, the middle part of the gear 21 is provided with a blind hole 22 communicating with the round pipe 2; gas is passed through the round pipe 2; No.1 hole 23, the No.1 hole 23 communicates with the blind hole 22; the gas in the circular pipe 2 is ejected from the No.1 hole 23 and burnt, further increasing the heating efficiency of the ring gear, thereby further increasing the quality and efficiency of the nitriding of the ring gear ; When the gear 21 drives the ring gear to rotate while carrying out the nitriding operation in the nitriding tank 14, the gas is injected into the round pipe 2 so that the gas is sprayed out after the round pipe 2, the blind hole 22 and the No. 1 hole 23 , the gas ejected from the No. 1 hole 23 is ignited to quickly heat the ring gear passing through the gear 21, which further improves the utilization rate of gas and increases the heating efficiency of the ring gear, thereby saving gas and further increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com