Device and method for heating rich oil to remove benzene by using coke oven riser pipe waste heat

An oil-rich, coke oven technology, which is applied in the heating of coke ovens, carbonization gas discharge devices, coke ovens, etc., can solve the problems of incomplete combustion, energy consumption, air pollution, etc., achieve fast heating speed, and realize environmental protection production , High heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

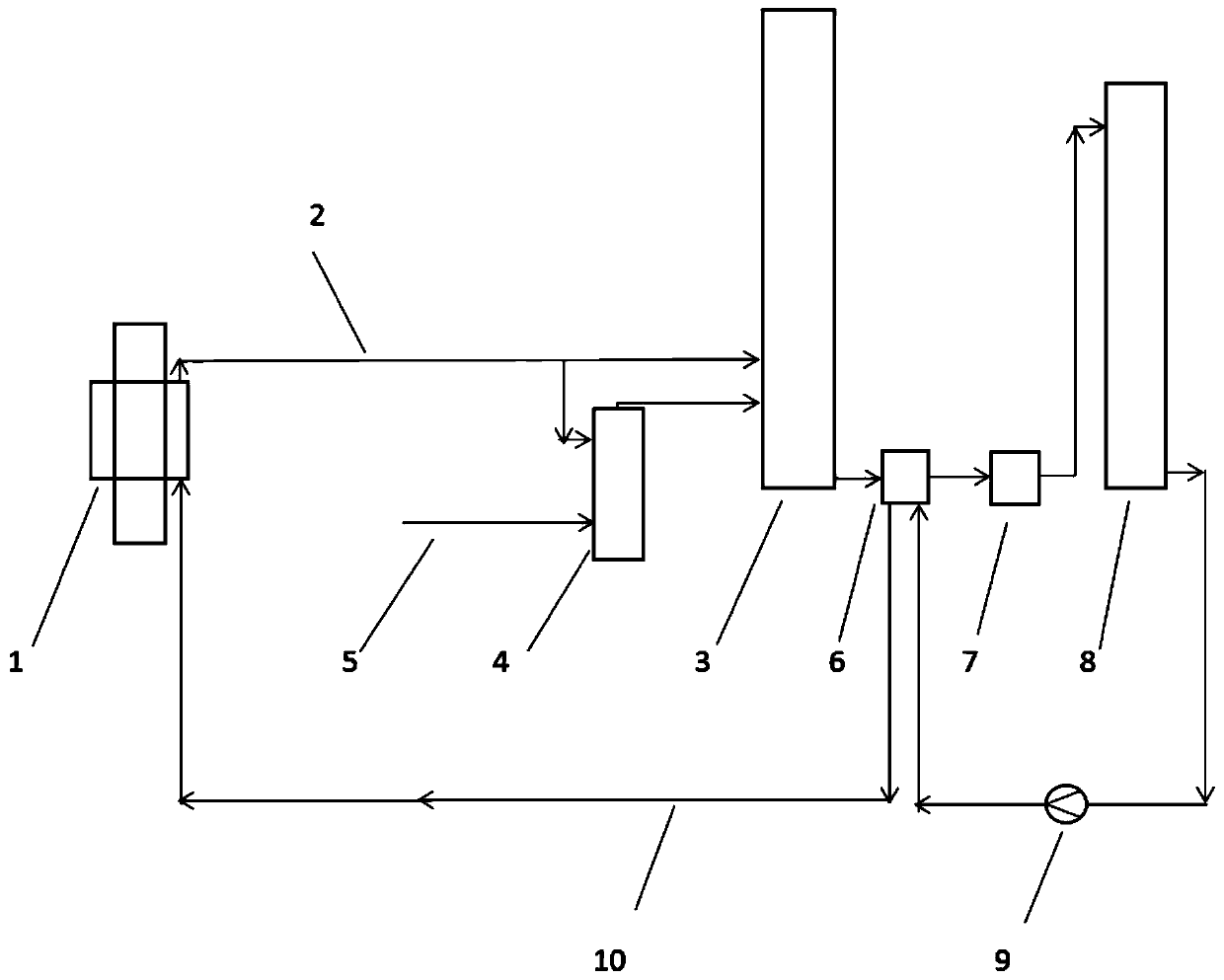

[0019] Referring to the accompanying drawings, through the description of the embodiments, the specific implementation of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the function and working principle of each part, and the manufacturing process And the method of operation and use, etc., are described in further detail to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concept and technical solutions of the present invention.

[0020] figure 1 It is a schematic diagram of a device for heating rich oil and removing benzene by using the waste heat of the coke oven riser, such as figure 1 Shown is a device for heating rich oil to remove benzene by using the waste heat of the coke oven riser tube, including a rich oil processor for heat exchange and distillation of rich oil, a rich oil regenerator, and lean oil processing for heat exchange and coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com