Preparation method of diaryl disulfide

A diaryl disulfide and sulfur powder technology, which is applied in the preparation of hydrogenated polysulfide/polysulfide, magnesium organic compounds, organic chemistry, etc., can solve the problems of high cost, large pollution, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

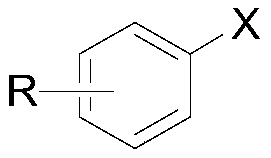

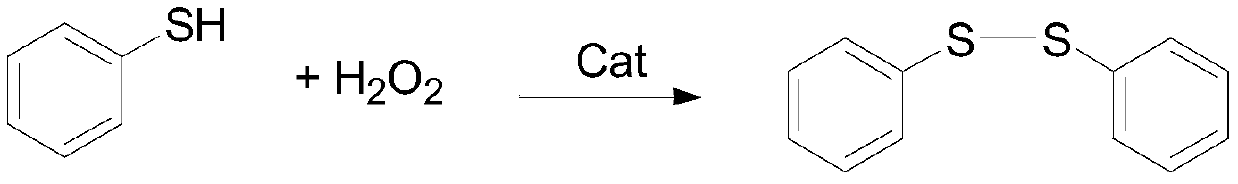

[0030] One embodiment of the present invention provides a method for preparing diaryl disulfides, comprising the steps of: reacting a halogenated aromatic hydrocarbon with magnesium powder to generate a Grignard reagent, then adding sulfur powder, and Under the action of the reaction, two aryl disulfides are obtained.

[0031] The preparation method uses cheap and easy-to-obtain halogenated aromatic hydrocarbons as synthetic raw materials to synthesize aromatic disulfide, firstly reacts it with magnesium powder to generate Grignard reagent, and then reacts with sulfur powder under the action of acid and oxidant to obtain disulfide disulfide. Aryl disulfides. The whole method process does not require heavy metal catalysis and complex ligands, and does not need to discharge materials in the middle. It is directly synthesized in one pot, and is environmentally friendly, with high conversion rate, high yield and purity, simple process and convenient operation, and is suitable for ...

Embodiment 1

[0056]

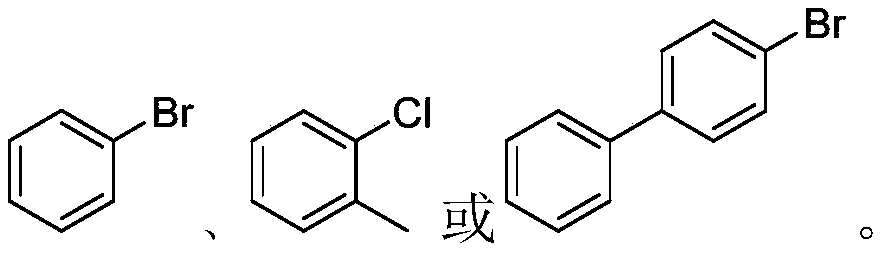

[0057]At room temperature, dissolve 80g of bromobenzene in 200mL of THF, stir evenly, under the protection of nitrogen, add 12g of magnesium chips into a three-necked flask with a thermometer, put a small amount of bromobenzene solution into a constant pressure dropping funnel, and add a small particle of iodine Elemental substance initiates the reaction, vigorously stirs and heats up to 60°C, the system begins to bubble and heat up, the reaction starts, slowly add the remaining bromobenzene solution dropwise, the process temperature is controlled at 45-60°C, after the dropwise addition, continue to stir for 1 hour, and the metal magnesium disappears completely , and then add sulfur powder 20g, reflux reaction 6-8h. Cool down to 5-10°C. Mix 200mL of 20wt% sulfuric acid solution and 100mL of 30wt% hydrogen peroxide evenly to prepare a mixed acid solution, slowly add it dropwise to the above reaction solution, the process control temperature is not higher than 20°C, ...

Embodiment 2

[0059]

[0060] At room temperature, dissolve 65g of o-chlorotoluene in 250mL of dimethyltetrahydrofuran, stir evenly, under the protection of nitrogen, add 12g of magnesium chips into a three-necked flask with a thermometer, put a small amount of bromobenzene solution into a constant pressure dropping funnel, and add 5mL Dibromoethane initiates the reaction, vigorously stirs and heats up to 65°C, the system starts to bubble and heat up, the reaction starts, slowly add the remaining o-chlorotoluene solution dropwise, the process temperature is controlled at 60-65°C, after the dropwise addition, continue to stir for 1 hour, Metal magnesium completely disappears, then add 20g of sulfur powder, and react at 60-65°C for 6-8h. Cool down to 5-10°C. Mix 200mL of 20wt% sulfuric acid solution and 100mL of 30wt% hydrogen peroxide to prepare a mixed acid solution, slowly add it dropwise to the above reaction solution, the process control temperature is not higher than 20°C, and contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com