Closed self-dredging type biological filter membrane assembly

A membrane module and biological filtration technology, used in biological treatment devices, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of shortened membrane life, high operating costs, high energy consumption, etc., to improve the sealing effect, reduce The effect of unnecessary consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

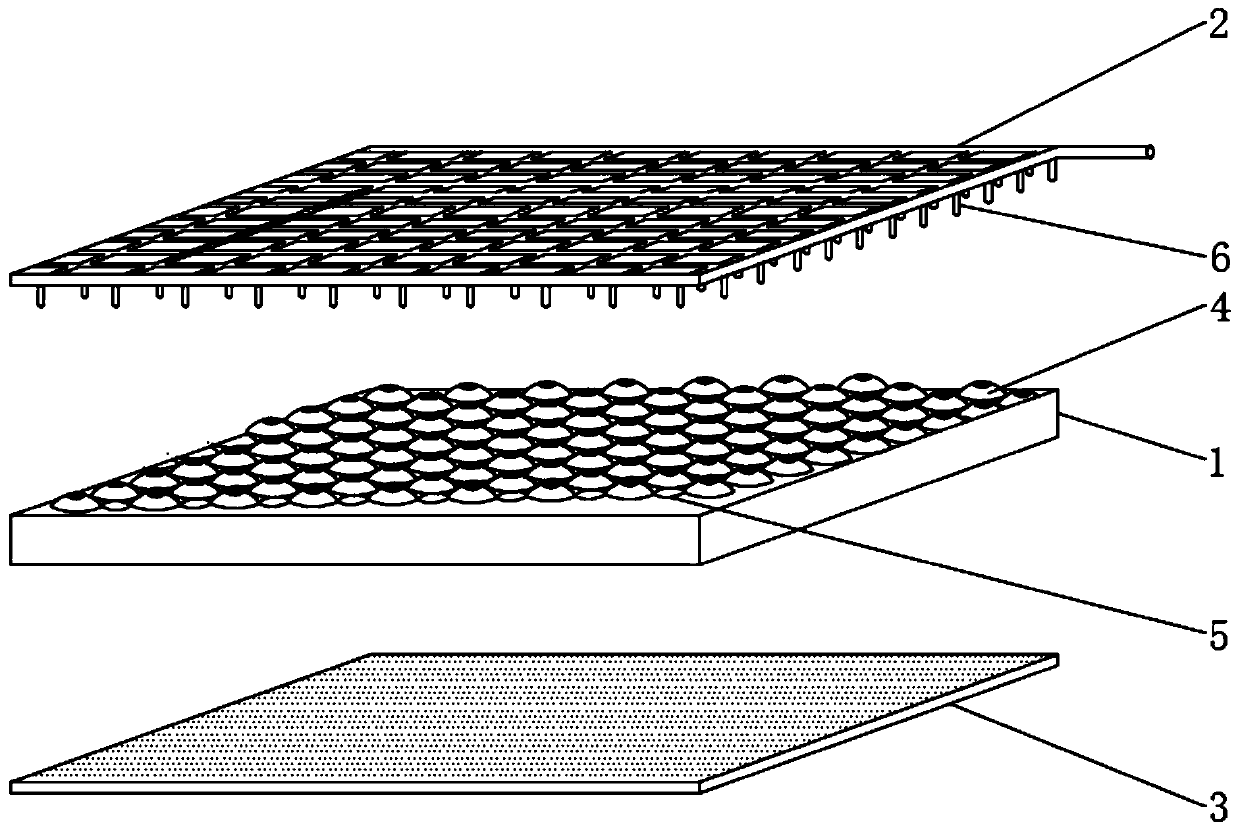

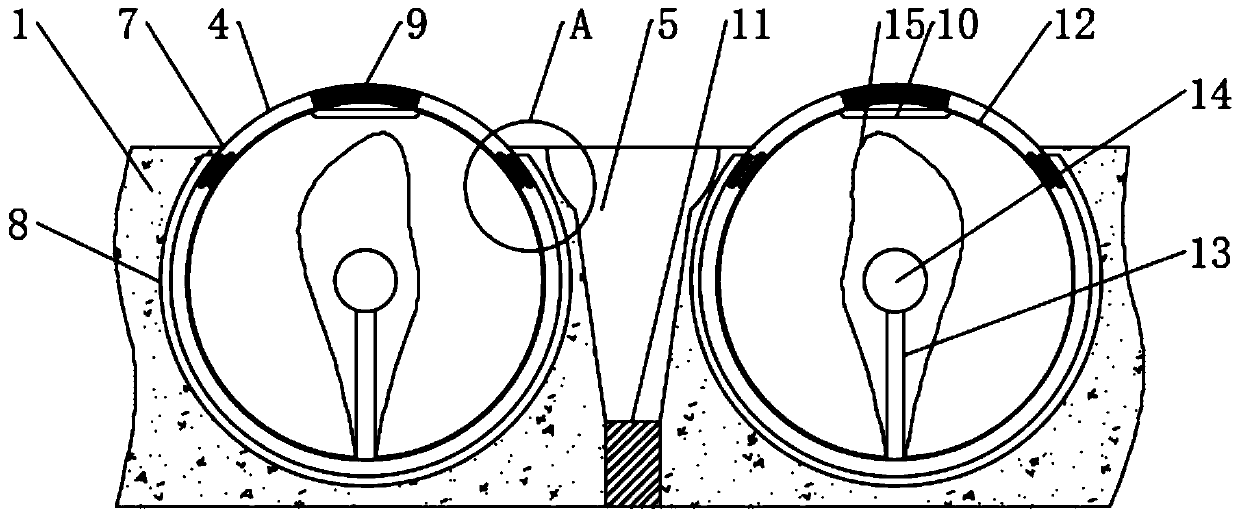

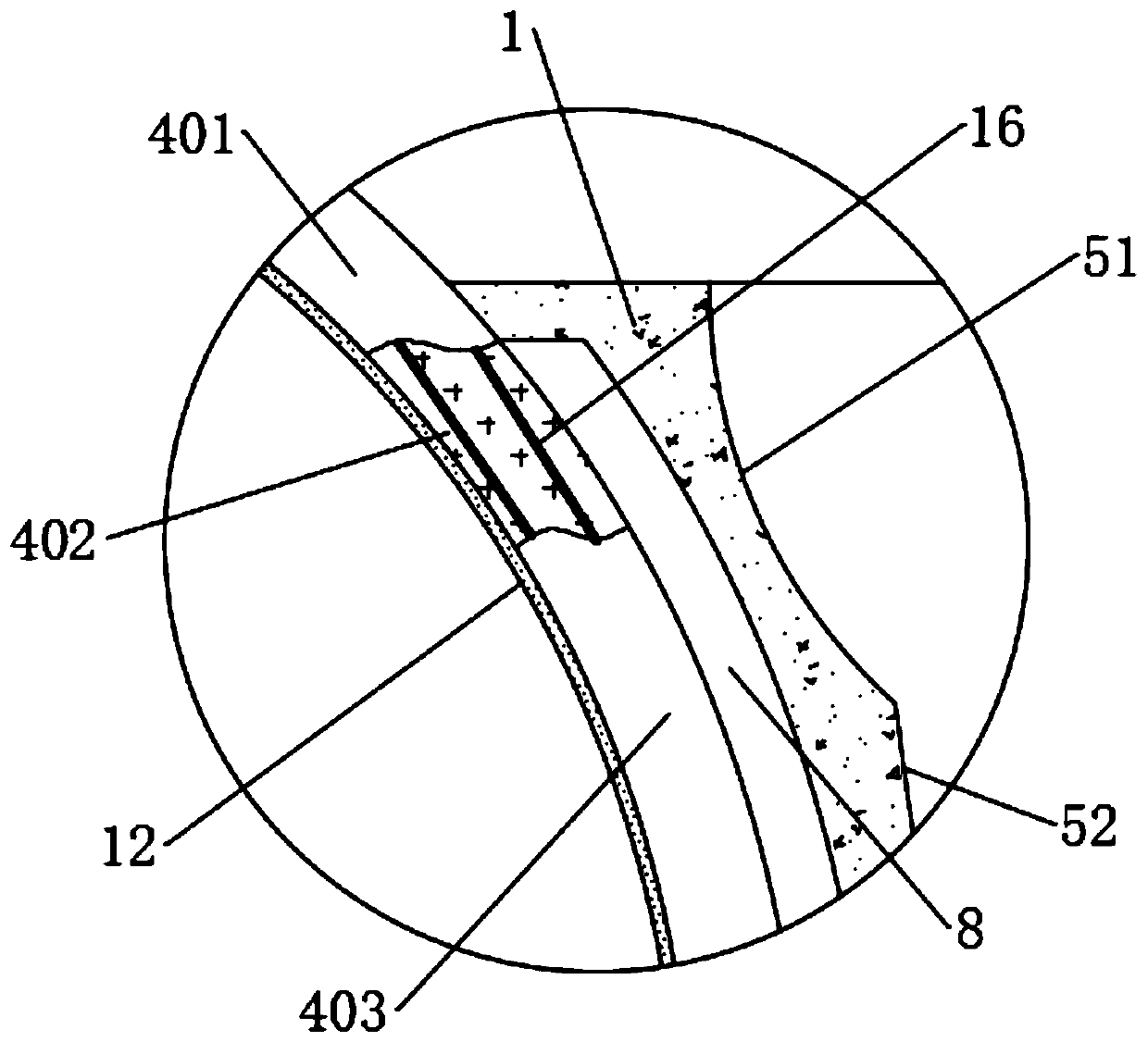

[0044] see figure 1 , a closed self-dragging type biofiltration membrane assembly, including a self-dragging filter 1, microorganisms are cultivated on the self-dragging filter 1, and a tubular filter 2 and a microfiltration membrane 3 are respectively installed at the upper and lower ends of the self-dragging filter 1 , the inner end of the tubular filter 2 is dug with a net-shaped flow channel, the outer end of the tubular filter 2 is fixedly connected with a connected air intake pipe, and the lower end of the tubular filter 2 is fixedly connected with a plurality of evenly distributed air supply pipes 6, and The gas filling pipe 6 matches the deformed oxygen storage ball 4 and communicates with the mesh flow channel. The tubular filter 2 reduces the filtration pressure of the self-draining filter 1 and the tubular filter 2 while preliminarily filtering large-diameter pollutants. At the same time, a connecting pipeline can be established with the deformed oxygen storage ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com