Inner hole welding protection tool and inner hole welding method

A technology for protecting tooling and inner holes. It is applied in the direction of providing/removing shielding gas devices, welding equipment, welding accessories, etc. It can solve the problems of reduced intergranular corrosion resistance, poor protection of pipe joints, and large welding stress. Good quality, convenient installation and positioning, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

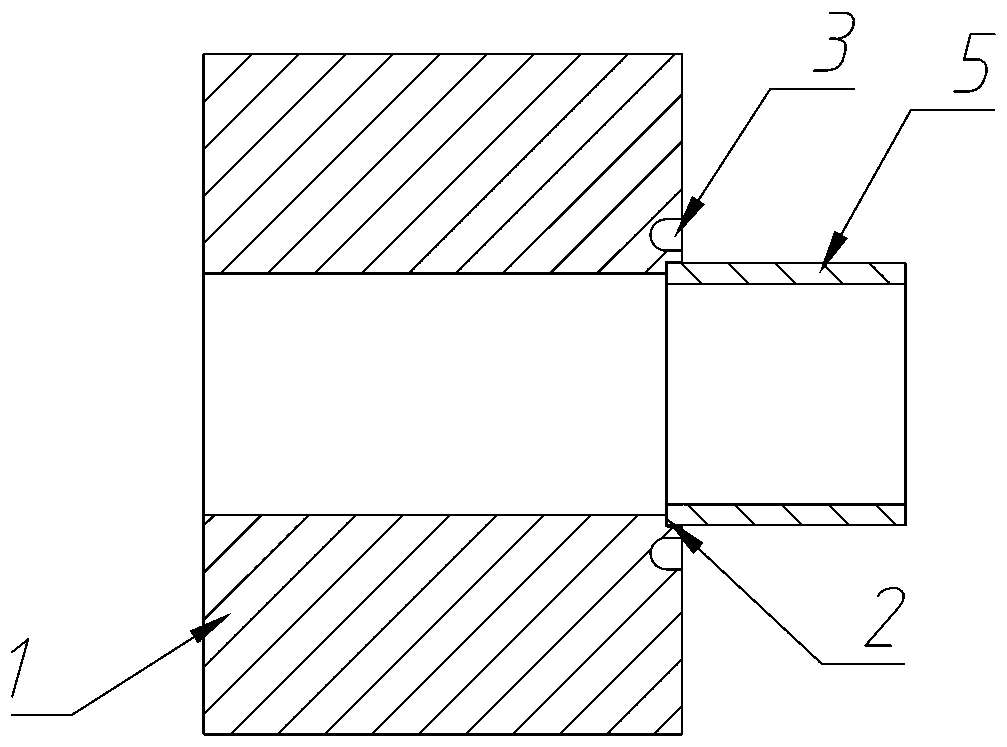

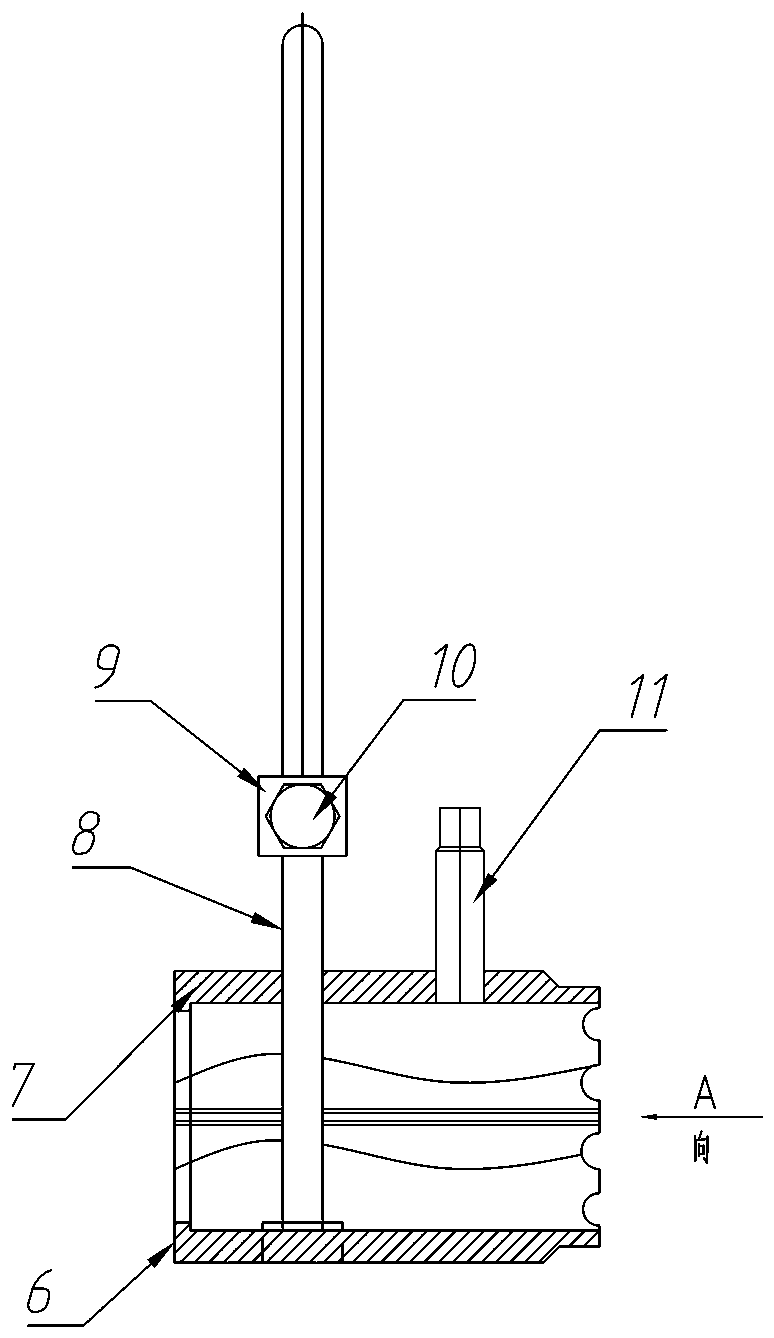

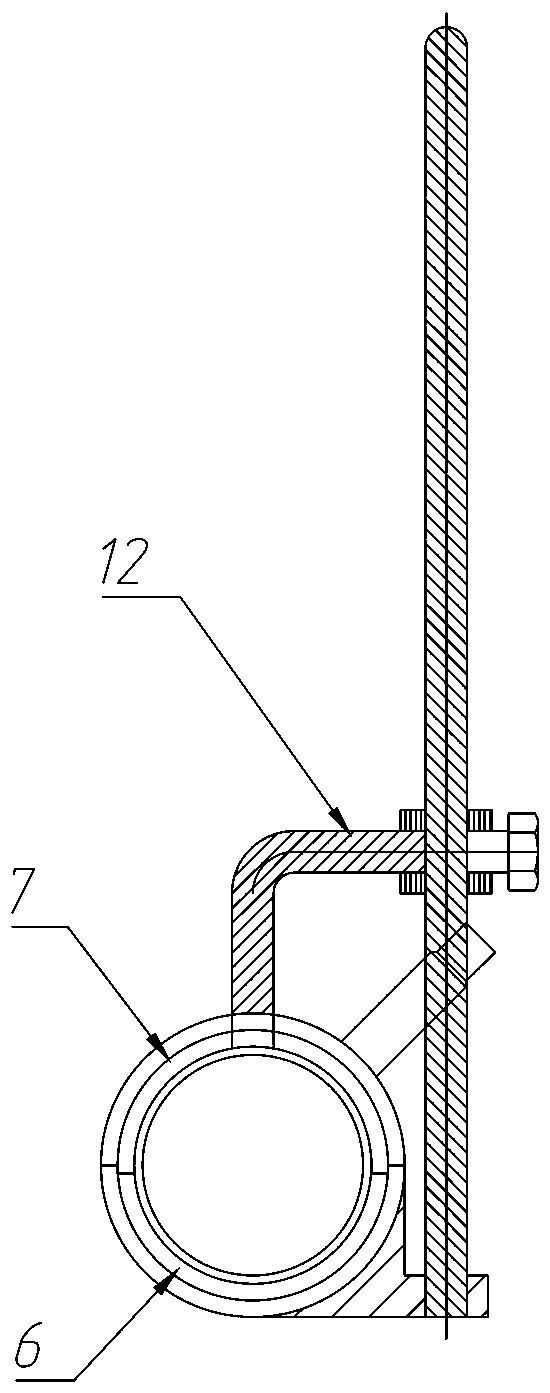

[0035] An inner hole welding protection tool of the present invention comprises an upper clamp body 7 and a lower clamp body 6, the upper clamp body 7 and the lower clamp body 6 are connected to form a hollow cylindrical clamp body, the upper clamp body 7 and the lower clamp body The clamp body 6 is connected by a sealing structure, and a fixed seat is fixedly connected to the outer peripheral surface of the lower clamp body 6 , and a pressure rod 12 is connected to the upper clamp body 7 , and a sleeve is connected to the end of the pressure rod 12 away from the upper clamp body 7 9. A slide rail 8 is fixedly connected to the fixed seat, and the sleeve 9 is sleeved on the slide rail 8 and connected with the slide rail 8 through a locking device. When the sleeve 9 slides on the slide rail 8, the upper clamp The concrete 7 and the lower clamp body 6 are close to or far away from each other;

[0036] The clamp body is also provided with an air intake pipe 11, and the vent pipe c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com