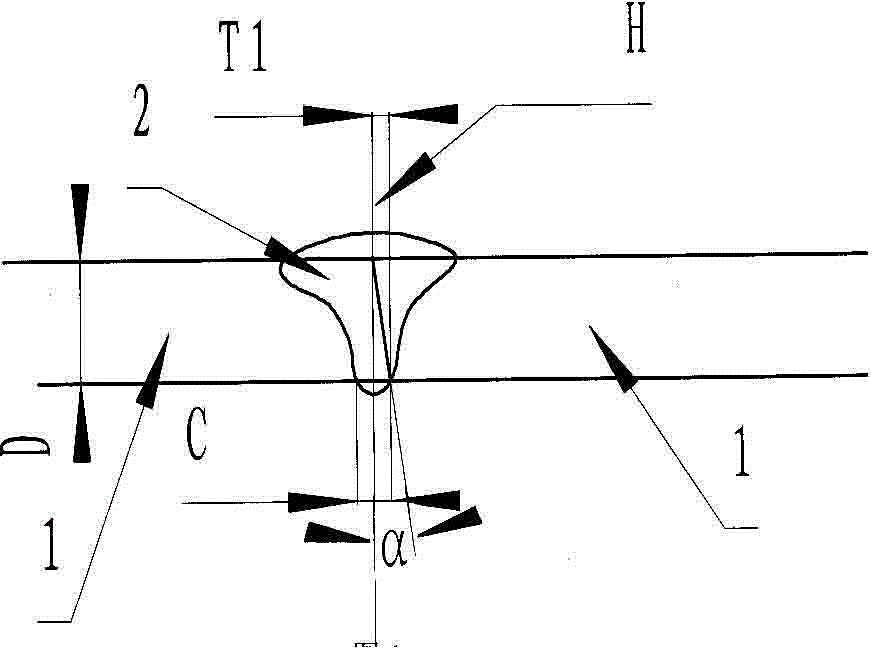

Compensating welding method of rake angle welding line of electron beam welding thin plate

A technology of electron beam welding and welding method, which is applied in the field of vacuum electron beam welding, which can solve the problems of undercut, shrinkage groove, influence on welding quality, and difficulty in ensuring back molding, etc., so as to avoid incomplete penetration and surface undercut , Improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

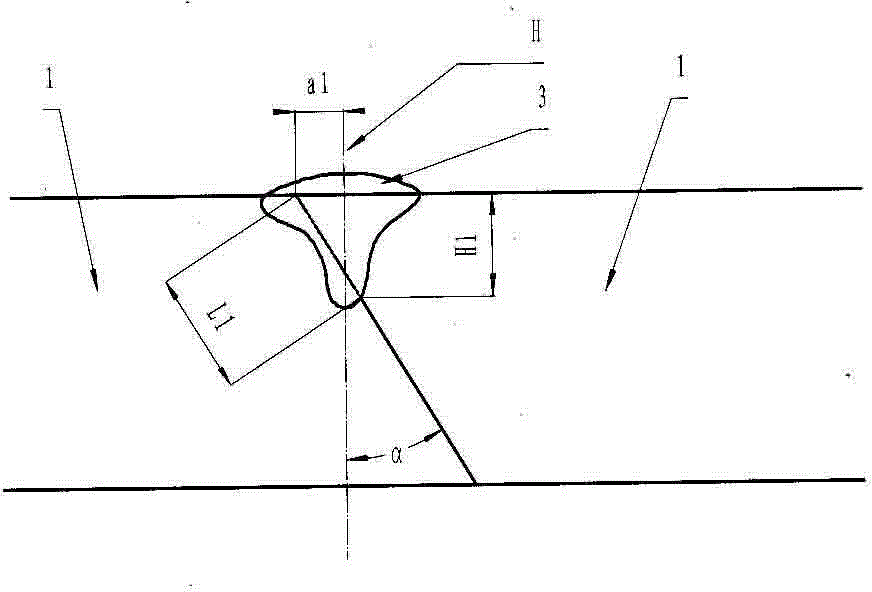

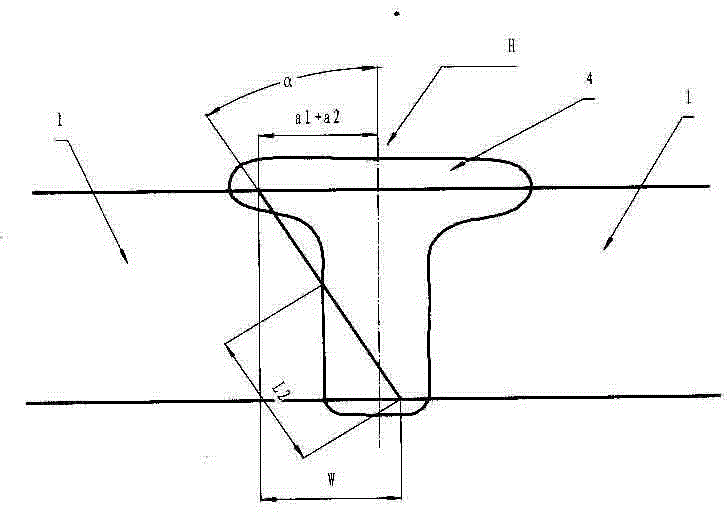

[0077] Example 1: The thickness of the part is 3mm, the butt joint angle of the oblique angle is 15.4°, the voltage of the electron gun is 55KV, and the distance between the electron gun is 190mm; the welding speed is 600mm / min, the welding current is 8mA, and the focusing current is 2.17-2.19A; take the positioning welding offset α1 =0.35 mm≤0.6 mm; for positioning welding, the surface weld width of the positioning welding is 1.5 mm, the stable minimum molten pool width is 0.6 mm, the stable penetration depth is 1 mm, and the end surface length of the oblique weld seam of the positioning welding is L1=1 / cos15.4° =1.037, such as Figure 4 shown.

[0078] Compensation welding: electron gun voltage 55KV, electron gun distance 190 mm; welding speed 700mm / min, welding current 35mA, focusing current 2.17A; offset α2=0.4 mm again on the basis of positioning welding offset, perform compensation welding, welding The thickness of the surface of the obtained weld is 3 mm, and the width...

Embodiment 1

[0103] 1.5 / L2=sin15.4°

[0104] L2=1.5 / sin15.4°=3.422

[0105] Part weld actual length

[0106] L=3 / cos15.4°=3.112

[0107] L1+L2=1.037+3.422=4.459>L=3.112

[0108] It can be seen from the above that through one offset compensation welding, the weld seam can make the weld seam of the 15.4° oblique angle butt joint parts completely merged.

Embodiment 2

[0109] Embodiment 2: The part thickness is 3mm, the butt joint angle of the oblique angle is 28.9°, the voltage of the electron gun is 55KV, and the distance between the electron gun is 190mm; the welding speed is 600mm / min, the welding current is 10mA, and the focusing current is 2.17-2.19A; take the positioning welding offset α1 =0.55 mm≤0.6 mm; for tack welding, the weld seam width on the tack welding surface is 1.5 mm, the minimum stable molten pool width is 0.6 mm, the stable penetration depth is 1 mm, and the molten pool includes the weld seam length L1=1 / cos28.9°=1.142 ,

[0110] Such as Figure 6 shown.

[0111] a1=0.55mm≤0.6mm

[0112] L1=1 / cos28.9°=1.142

[0113] Compensation welding: electron gun voltage 55KV, electron gun distance 190 mm; welding speed 600mm / min, welding current 29mA, focusing current 2.17A; offset α2=0.8 mm again on the basis of positioning welding offset, perform compensation welding, welding The formed thickness of the obtained weld surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com