Method and device for preventing root defects of friction stir welding of launch vehicle tank longitudinal seam

A technology for friction stir welding and launch vehicles, which is applied to the propulsion system devices of aerospace vehicles, welding equipment, non-electric welding equipment, etc., can solve the problem of inability to measure the distance between the stirring needle and the backing plate in real time, and prevent incomplete penetration defects. , The effect of preventing incomplete penetration

Active Publication Date: 2013-07-24

CAPITAL AEROSPACE MACHINERY

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the board, due to the obstruction of the workpiece, the distance between the stirring needle and the backing plate cannot be measured in real time, and there is a hidden danger of root defects

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0025] d. by placing the camera on the dial gauge 7, real-time observation of the welding process.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a method and a device for preventing the root defects of the friction stir welding of the longitudinal seam of the carrier rocket storage tank. It is provided with a flat ruler clamping mechanism on the flat ground on one side of the backing plate, and the flat ruler is erected on the flat ruler clamping mechanism. The plates are parallel; the clamping mechanism of the measuring tool is fixedly connected with the clamping mechanism of the stirring head, and the dial gauge is fixedly installed on the clamping mechanism of the measuring tool, and the dial gauge is vertically set close to the flat ruler; the vertical distance between the stirring needle and the backing plate The change value is equal to the vertical drop / rise distance value of the stirring head clamping mechanism read from the dial gauge along the ruler. The method and device of the invention realize the real-time measurement of the distance change between the stirring needle and the backing plate, thereby preventing the occurrence of incomplete penetration defects and the defects of the stirring needle piercing the backing plate, and effectively improving the success rate of friction stir welding.

Description

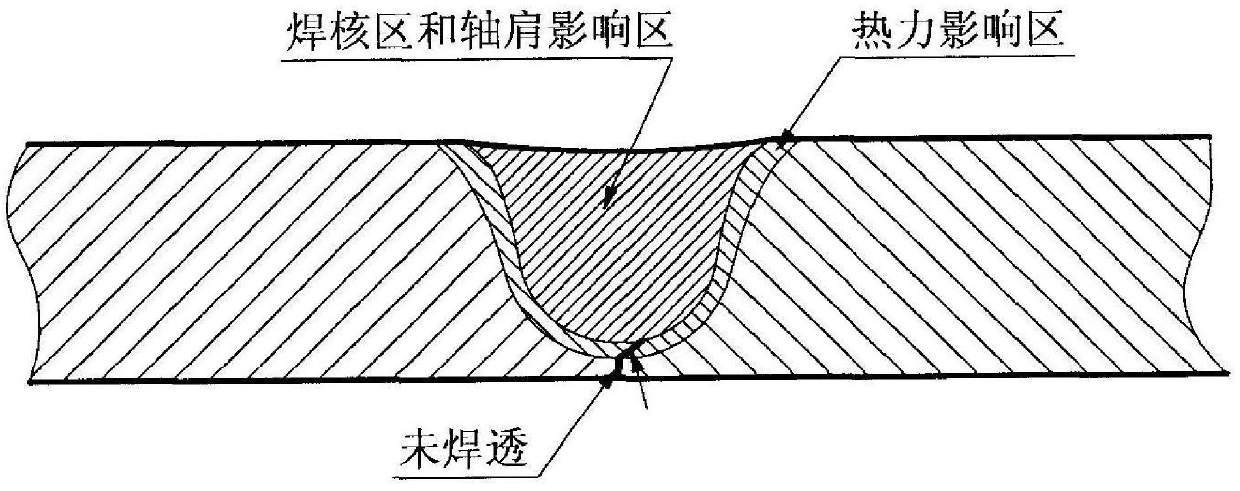

Method and device for preventing root defects of friction stir welding root of launch vehicle storage tank longitudinal seam Technical field The present invention belongs to aerospace product welding processing method and device, be specifically related to a kind of for preventing launch vehicle tank Method and device for root defect of longitudinal seam friction stir welding. Background technique Friction stir welding technology is a kind of solid phase connection new technology invented by British Welding Institute in 1991, which is based on This principle is shown in Figure 1. The high-speed rotating stirring head plunges into the workpiece and moves along the welding direction. When the stirring head is in contact with the workpiece Frictional heat is generated at the part, so that the nearby metal forms a plastic softening layer, and the softening layer is filled and stirred under the action of the rotation of the stirring head The cavity formed behind the needle...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K20/12B23K20/26B64G1/40

Inventor 刘宪力孙忠绍赵衍华杜岩锋刘景铎朱平萍

Owner CAPITAL AEROSPACE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com