Argon arc welding method for exhaust casing components

A technology of argon arc welding and exhaust machine, which is applied in the direction of welding equipment, arc welding equipment, manufacturing tools, etc. It can solve the problems of welding cracks and low pass rate of parts, achieve uniform heating, good welding quality, and ensure the formation of weld seams Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Joint preparation

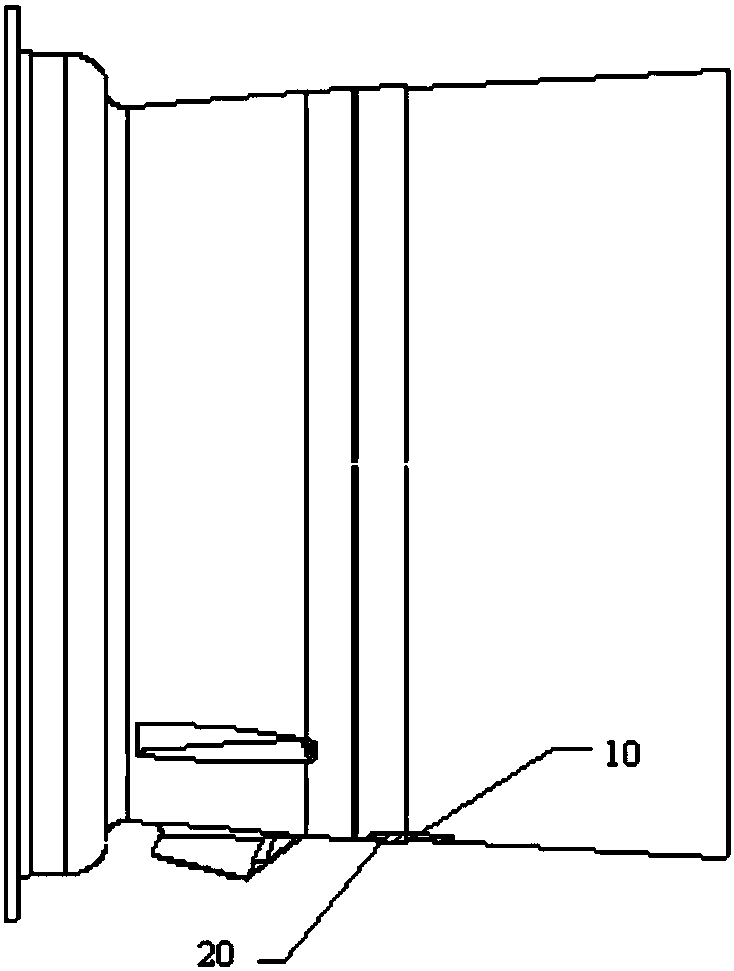

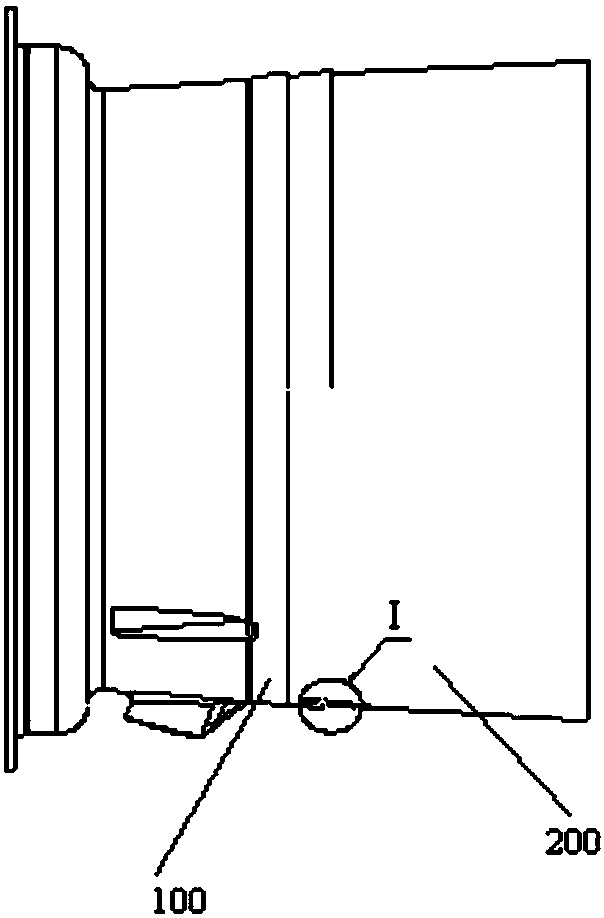

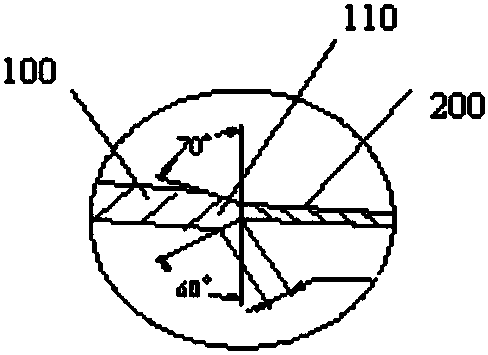

[0054] Machining is carried out on the part to be welded of the exhaust support 100, so that the wall thickness of the part to be welded of the exhaust support 100: the wall thickness of the part to be welded of the outer ring 200 of the exhaust section = 0.9: 1.1.

[0055] 2. Cleaning before welding

[0056] First, mechanically polish the exhaust bearing 100 to see metallic luster within 10mm to 15mm of the welded part, so as to remove the scale and so on. Then use a clean white silk cloth stained with analytical pure acetone to wipe the surface of the exhaust support 100 and the outer ring 200 of the exhaust section to be welded to remove dirt such as oil.

[0057] 3. Assembly combination

[0058] Put the exhaust casing assembly into the argon arc welding fixture, and then fix the assembled parts on the welding turntable of the automatic argon tungsten arc welding machine.

[0059] 4. Tack welding

[0060] The manual tungsten argon arc weldi...

Embodiment 2

[0073] 1. Joint preparation

[0074] Machining is performed on the part to be welded of the exhaust support 100 , so that the wall thickness of the part to be welded on the exhaust support 100 : the wall thickness of the part to be welded on the outer ring 200 of the exhaust section = 1:1.

[0075] 2. Cleaning before welding

[0076] First, mechanically polish the exhaust bearing 100 to see metallic luster within 10mm to 15mm of the welded part, so as to remove the scale and so on. Then use a clean white silk cloth stained with analytical pure acetone to wipe the surface of the exhaust support 100 and the outer ring 200 of the exhaust section to be welded to remove dirt such as oil.

[0077] 3. Assembly combination

[0078] Put the exhaust casing assembly into the argon arc welding fixture, and then fix the assembled parts on the welding turntable of the automatic argon tungsten arc welding machine.

[0079] 4. Tack welding

[0080] The manual tungsten argon arc welding me...

Embodiment 3

[0094] 1. Joint preparation

[0095] Machining is carried out on the part to be welded of the exhaust support 100, so that the wall thickness of the part to be welded on the exhaust support 100: the wall thickness of the part to be welded on the outer ring 200 of the exhaust section=1.1:0.9.

[0096] 2. Cleaning before welding

[0097] First, mechanically polish the exhaust support 100 to see metallic luster within 10mm to 15mm of the welded part, so as to remove the scale and so on. Then use a clean white silk cloth dipped in analytical pure acetone to wipe the surface of the exhaust support 100 and the outer ring 200 of the exhaust section to be welded to remove dirt such as oil.

[0098] 3. Assembly combination

[0099] Put the exhaust casing assembly into the argon arc welding fixture, and then fix the assembled parts on the welding turntable of the automatic argon tungsten arc welding machine.

[0100] 4. Tack welding

[0101] The manual tungsten argon arc welding met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com