Graphene water-borne heating film conductive slurry

A conductive paste, alkene water technology, applied in heating element materials, electric heating devices, electrical components, etc., can solve the problems of agglomeration, difficult dispersion, poor compatibility, etc., achieve thin coating thickness, high energy conversion, high heat effect of radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

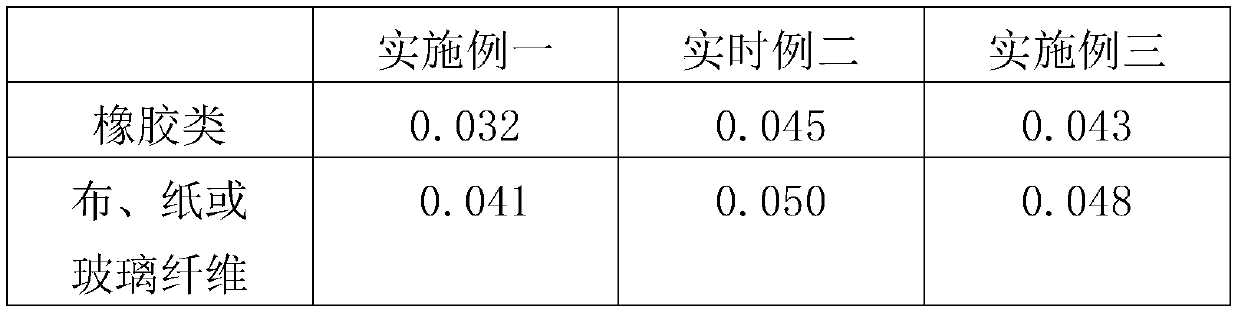

Examples

Embodiment 1

[0025] Preparation of slurry A, the choice of tube diameter is 7-15nm, tube length 8g of carbon nanotubes of 5-15um, the first dispersant is carbon nanotube dispersant (TNWDIS) 1.2g, deionized water 90.8g, then carry out Mix and stir, carry out pre-dispersion treatment, after standing for 5 minutes, stir at a speed of 600-1200r / min, stir for 10 minutes, and obtain about 100g of finely dispersed slurry A.

[0026] The particle size is 15-20nm and the specific surface area is greater than 1000m 2 / g spherical conductive carbon black 12g, amino acid ester copolymer dispersant 1.5g, deionized water 86.5g, mix and stir first, carry out pre-dispersion treatment, after standing for 5 minutes, stir with 600-1200r / min speed, After stirring for 10 minutes, about 100 g of finely dispersed slurry B was obtained.

[0027] Weigh 8.5g of modified graphene, 0.8g of polyethylene wax, 0.4g of one or more of polytetrafluoroethylene or polyvinylidene fluoride; 90.3g of deionized water, grind and...

Embodiment 2

[0029] Preparation of slurry A, the choice of tube diameter is 7-15nm, 5g of carbon nanotubes with a tube length of 5-15um, the first dispersant is 1g of carbon nanotube dispersant (TNWDIS), 94g of deionized water, and then mixed and stirred , carry out pre-dispersion treatment, after standing for 5 minutes, stir at a speed of 600-1200r / min, stir for 10 minutes, and obtain about 100g of finely dispersed slurry A.

[0030] The particle size is 15-20nm and the specific surface area is greater than 1000m 2 / g of spherical conductive carbon black 10g, amino acid ester copolymer dispersant 1.5g, deionized water 88.5g, mix and stir first, carry out pre-dispersion treatment, after standing for 5 minutes, stir with 600-1200r / min speed, After stirring for 10 minutes, about 100 g of finely dispersed slurry B was obtained.

[0031] Weigh 7g of modified graphene, 0.6g of polyethylene wax, 0.3g of one or more of polytetrafluoroethylene or polyvinylidene fluoride; 92.1g of deionized water,...

Embodiment 3

[0033] Preparation of slurry A, the choice of tube diameter is 7-15nm, 10g of carbon nanotubes with a tube length of 5-15um, the first dispersant is 3g of carbon nanotube dispersant (TNWDIS), 87g of deionized water, and then mixed and stirred , carry out pre-dispersion treatment, after standing for 5 minutes, stir at a speed of 600-1200r / min, stir for 10 minutes, and obtain about 100g of finely dispersed slurry A.

[0034] The particle size is 15-20nm and the specific surface area is greater than 1000m 2 / g of spherical conductive carbon black 15g, amino acid ester copolymer dispersant 3g, deionized water 82g, mix and stir first, carry out pre-dispersion treatment, stir with 600-1200r / min speed after standing for 5 minutes, stir 10 Minutes, about 100 g of finely dispersed slurry B was obtained.

[0035] Weigh 10g of modified graphene, 1g of polyethylene, 0.5g of one or more of polytetrafluoroethylene or polyvinylidene fluoride; deionized water is 88.5g, grind and disperse afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com