A conductive polymer-coated silicon-based negative electrode sheet and its preparation method and application

A conductive polymer and silicon-based negative electrode technology, applied in negative electrodes, battery electrodes, active material electrodes, etc., to achieve environmental friendliness, controllable reaction rate, improved interface performance and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

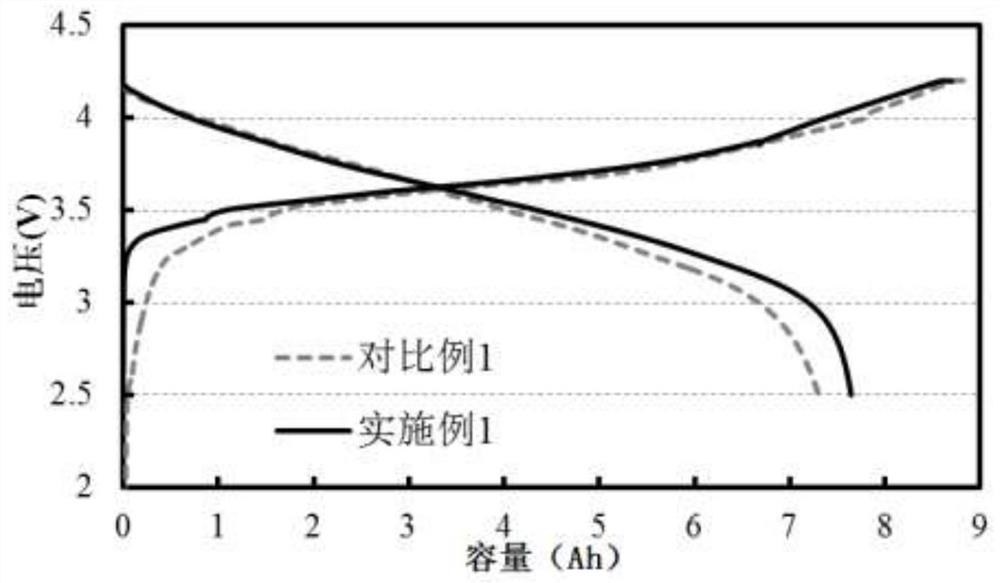

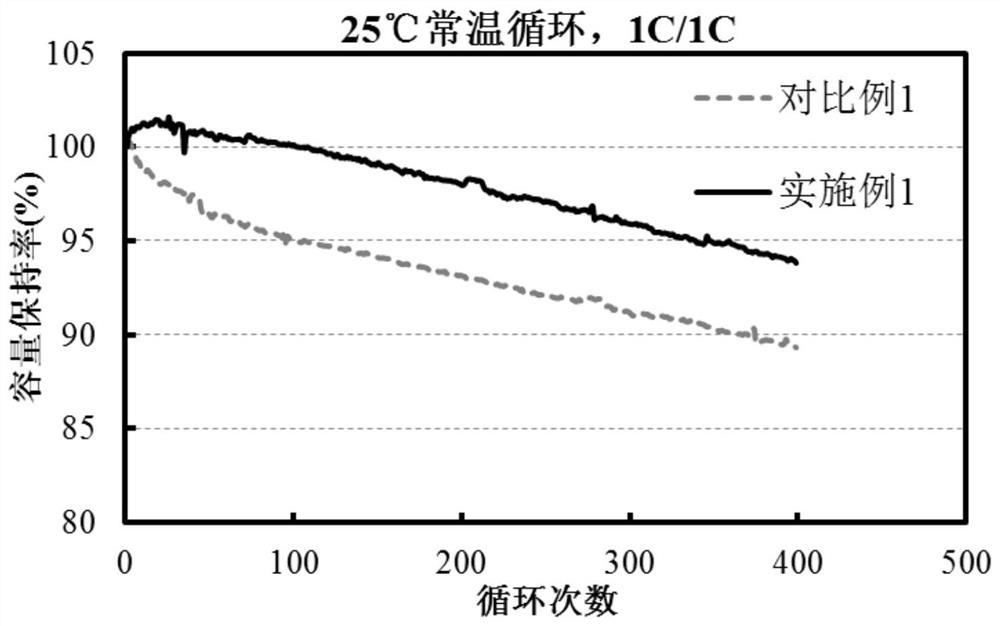

[0027] Example 1

[0028] The commercialized SiO / C material (600mAh / g in Example 1) is mixed with conductive agent and binder according to the mass ratio of 94.5:2:3.5, coated, rolled, slitting, die-cutting, A silicon-based negative electrode sheet is obtained.

[0029] Dissolve 1mol LiCl in 1L 1-ethyl-3-methylimidazolium tetrafluoroborate ([EMIm][BF 4]), add 1 mol of pyrrole (py) monomer, magnetically stir to dissolve and disperse evenly to obtain a mixed solution. Add the above mixed solution, silicon-based negative electrode sheet, and metal lithium sheet into the electrolytic cell respectively, apply an external power supply, control the voltage to 0.5V, and the reaction time is 6h. Carry out electrochemical self-polymerization reaction, and generate a conductive polymer film with a thickness of 20nm on the surface of the silicon-based negative electrode sheet; after the reaction, use the silicon-based negative electrode sheet as the positive electrode and the metal lith...

Embodiment 2

[0034] Example 2

[0035] The commercialized SiO / C material (420mAh / g in Example 2) is mixed with conductive agent and binder according to the mass ratio of 94.5:2:3.5, coated, rolled, slitting, die-cutting, A silicon-based negative electrode sheet is obtained.

Embodiment 3

[0037] Example 3

[0038] The commercialized SiO / C material (450mAh / g in Example 3) is mixed with conductive agent and binder according to the mass ratio of 94.5:2:3.5, coated, rolled, slitting, die-cutting, A silicon-based negative electrode sheet is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com