A method for changing the color of cracked heavy resin embossed leather

An embossing and resin technology is applied in the field of color change of cracked heavy resin embossed leather, which can solve the problems of unfriendly environment and human body, uneven color of leather blank, performance discount such as hand feeling, etc., and achieve good fading effect, environment and human body. Friendly, feel and other properties maintain good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

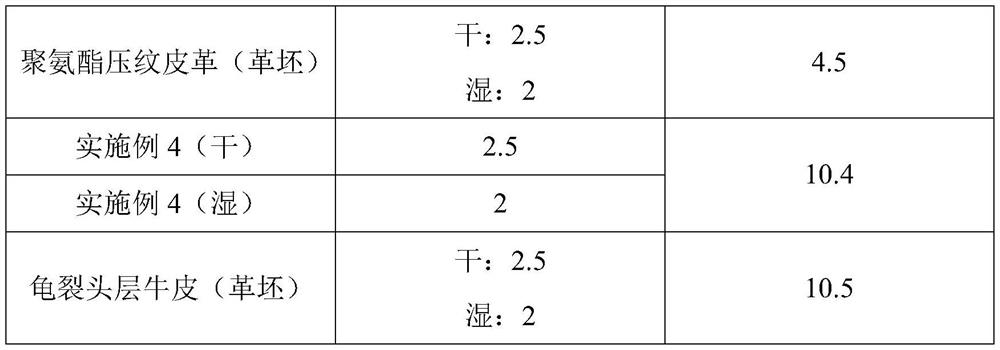

Examples

Embodiment 1

[0037] A method for changing the color of cracked heavy resin embossed leather, comprising the following steps:

[0038] S1. Use the stock leather as the leather base, add the leather base into the drum, and add 135-165% water into the drum according to the mass percentage of the leather base, control the water temperature at 48-52°C, and rotate for 25-35 minutes Back drain;

[0039] S2, according to the mass percentage of leather base, add 95~105% water, 2.5~3.5% ethylene glycol ether, 0.46~0.56% degreasing agent, 0.45~0.55% baking soda in the drum, control The water temperature is 48-52°C, continue to rotate for 110-130 minutes before draining;

[0040] S3, then wash the leather base processed in step S2 once, and drain;

[0041] S4, according to the mass percentage of leather base, add 95~105% water, 2.5~3.5% ethylene glycol ether, 0.46~0.56% degreasing agent, 0.45~0.55% baking soda in the drum, control The water temperature is 48-52°C, and the liquid is discharged after...

Embodiment 2

[0061] A method for changing the color of cracked heavy resin embossed leather, comprising the following steps:

[0062] S1, use the stock leather as the leather base, add the leather base into the drum, and add 135% water into the drum according to the mass percentage of the leather base, control the water temperature to 52°C, and drain the liquid after rotating for 25 minutes;

[0063] S2. Add 95% of water, 2.5% of ethylene glycol ether, 0.46% of degreaser, and 0.45% of sodium bicarbonate into the drum according to the mass percentage of the leather base, control the water temperature to 52°C, and continue to rotate for 110 min Back drain;

[0064] S3, then wash the leather base processed in step S2 once, and drain;

[0065] S4. According to the mass percentage of the leather base, add 95% water, 2.5% ethylene glycol ether, 0.46% degreaser, and 0.45% baking soda into the drum, control the water temperature to 52°C, and rotate for 82 minutes drainage;

[0066] S5, then per...

Embodiment 3

[0075] A method for changing the color of cracked heavy resin embossed leather, comprising the following steps:

[0076] S1, use the stock leather as the leather base, add the leather base into the drum, and add 165% water into the drum according to the mass percentage of the leather base, control the water temperature to 48°C, and drain the liquid after rotating for 35 minutes;

[0077] S2. Add 105% water, 3.5% ethylene glycol ethyl ether, 0.56% degreasing agent, and 0.55% baking soda to the drum according to the mass percentage of the leather base, control the water temperature to 48°C, and continue to rotate for 130 minutes Back drain;

[0078] S3, then wash the leather base processed in step S2 once, and drain;

[0079] S4. According to the mass percentage of the leather base, add 105% water, 3.5% ethylene glycol ether, 0.56% degreaser, and 0.55% baking soda into the drum, control the water temperature to 48°C, and rotate for 98 minutes drainage;

[0080] S5, then perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com