Refining method of crabapple seed crude oil

A technology of crabapple seeds and crude oil, applied in the field of edible oil, which can solve the problems of toxicity, high acid value, and not being developed and utilized as edible oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

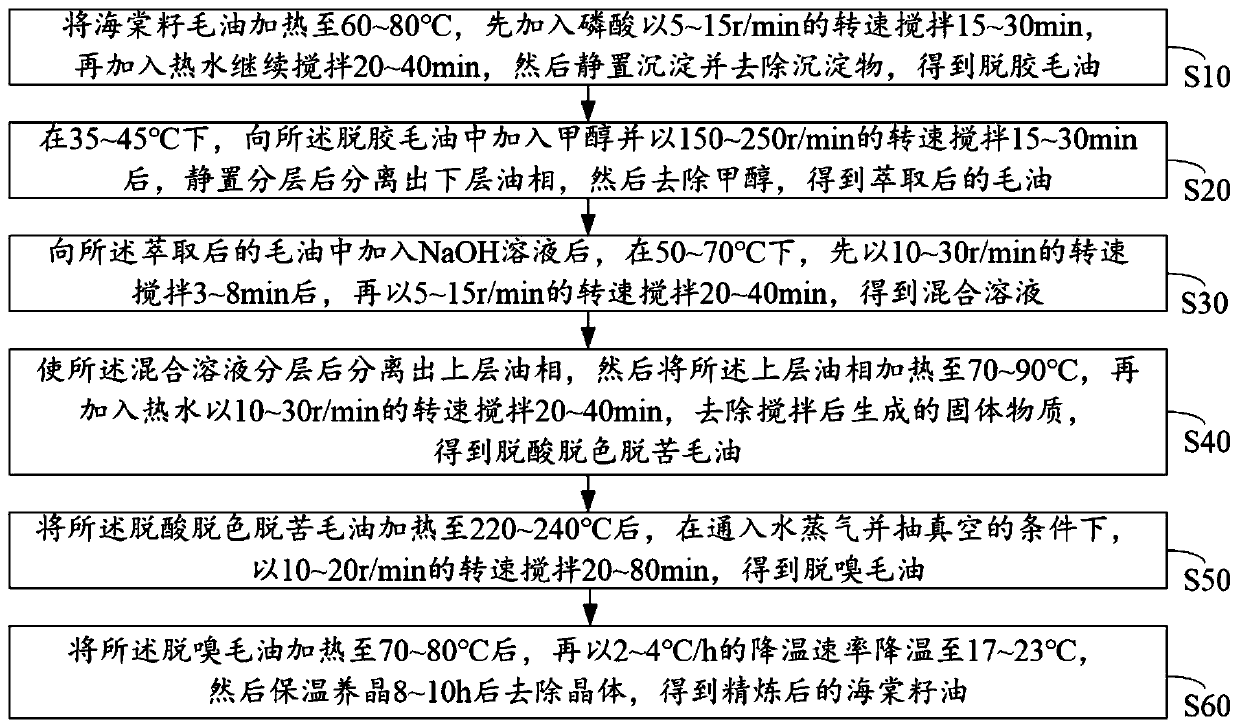

Method used

Image

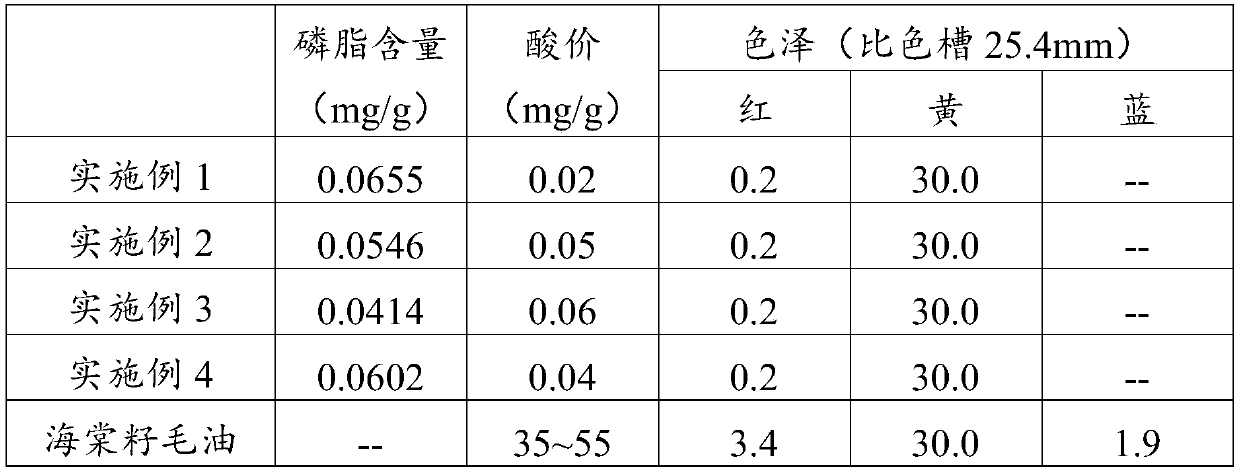

Examples

Embodiment 1

[0059] (1) Weigh the crabapple seed crude oil and heat it to 70°C, first add phosphoric acid with a mass concentration of 85% according to 0.1% of the mass of the crabapple seed crude oil, stir at a speed of 10r / min for 25min, and then Add 4% of the oil quality into hot water at a temperature of 90°C, continue stirring at the same rotational speed for 30 minutes, leave to settle for 2 hours after stirring, remove the precipitate, and obtain degummed crude oil;

[0060] (2) At 40°C, according to the ratio of degummed crude oil:methanol (mass:volume) = 1:2.5, add methanol to the degummed crude oil and stir rapidly at a speed of 200r / min for 25min, and then separate after standing for 2h The lower oil phase was taken out, and then the step of adding methanol to the lower oil phase and standing for stratification was repeated 3 times, and the lower oil phase obtained by the last separation was rotary-evaporated at 70° C. to remove methanol, and the extracted crude oil was obtained;...

Embodiment 2

[0066] (1) Heat the crabapple seed crude oil to 60°C after weighing, first add phosphoric acid with a mass concentration of 90% according to 0.05% of the mass of crabapple seed crude oil, stir at a speed of 5r / min for 30min, and then Add 2% of the oil mass into hot water at a temperature of 95°C, continue stirring at the same speed for 20 minutes, leave to settle for 3 hours after stirring, remove the precipitate, and obtain degummed crude oil;

[0067] (2) At 45°C, according to the ratio of degummed crude oil: methanol (mass: volume) = 1:2, methanol was added to the degummed crude oil and stirred rapidly at a speed of 150r / min for 15min, and then separated after standing for 3h The lower oil phase was taken out, and then the step of adding methanol to the lower oil phase and standing for stratification was repeated 3 times, and the lower oil phase obtained by the last separation was rotary-evaporated at 80° C. to remove methanol, and the extracted crude oil was obtained;

[0...

Embodiment 3

[0073] (1) Weigh the crabapple seed crude oil and heat it to 80°C, first add phosphoric acid with a mass concentration of 80% according to 0.15% of the mass of the crabapple seed crude oil, stir at a speed of 15r / min for 15min, and then follow the crabapple seed hair Add 5% of the oil mass into hot water at a temperature of 95°C, continue stirring for 40 minutes at the same rotational speed, and leave to settle for 1.5 hours after stirring, remove the precipitate, and obtain degummed crude oil;

[0074] (2) At 35°C, according to the ratio of degummed crude oil:methanol (mass:volume) = 1:2.8, add methanol to the degummed crude oil and stir rapidly at a speed of 250r / min for 30min, then let it stand for 1.5h The lower oil phase was separated, and then the step of adding methanol to the lower oil phase and standing for stratification was repeated twice, and the lower oil phase obtained by the last separation was rotary-evaporated at 60° C. to remove methanol to obtain the extracte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com