Fast-crystallization and high-crystallinity polylactic acid modification method

A technology of high crystallinity and polylactic acid, which is applied in the field of rapid crystallization and high crystallinity polylactic acid modification, can solve the problems of low crystallinity of polylactic acid and limit the application of polylactic acid, shorten the molding cycle, improve mechanical properties, and reduce crystallization effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

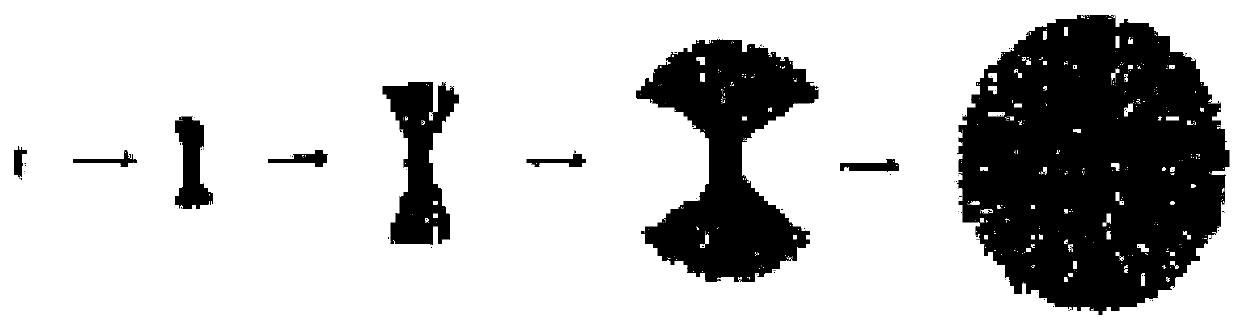

Image

Examples

Embodiment 1

[0024] A kind of rapid crystallization high crystallinity polylactic acid modification method, comprises the following steps:

[0025] Step 1: Melt and extrude carbon fiber, L-polylactic acid, D-polylactic acid, polyglycolic acid, and starch through a twin-screw extruder according to a certain ratio, and the extrusion temperature is 160°C to obtain a nucleating agent. Among them, The starch content is 5%, wherein the ratio of the L-polylactic acid, D-polylactic acid, talcum powder and polymethacrylate is 80:50:1.2:1;

[0026] Step 2: In parts by weight, 55 parts of semi-crystalline polylactic acid, 0.5 part of polymer-type crystallization accelerator, 0.1 part of nucleating agent, and 1 part of plasticizer, the semi-crystalline polylactic acid is preferably semi-crystalline Poly L-lactic acid, stir evenly to obtain a mixture, mix 92 parts of the mixture and 2 parts of polymer crystallization accelerator in a ball mill, the mixing temperature is above 80°C, mix for 0.5h, and pl...

Embodiment 2

[0031] A kind of rapid crystallization high crystallinity polylactic acid modification method, comprises the following steps:

[0032] Step 1: Melt and extrude carbon fiber, L-polylactic acid, D-polylactic acid, polyglycolic acid, and starch through a twin-screw extruder according to a certain ratio, and the extrusion temperature is 190°C to obtain a nucleating agent. Among them, The starch content is 4%, wherein the ratio of the L-polylactic acid, D-polylactic acid, talcum powder and polymethacrylate is 100:75:2:1;

[0033] Step 2: In parts by weight, 95 parts of semi-crystalline polylactic acid, 2 parts of polymer crystallization accelerator, 10 parts of nucleating agent, and 3 parts of plasticizer, the semi-crystalline polylactic acid is preferably semi-crystalline Poly L-lactic acid, stir evenly to obtain a mixture, mix 98 parts of the mixture and 8 parts of polymer crystallization accelerator in a ball mill, the mixing temperature is above 85°C, mix for 1.5h, and place in...

Embodiment 3

[0038] A kind of rapid crystallization high crystallinity polylactic acid modification method, comprises the following steps:

[0039]Step 1: Melt and extrude carbon fiber, L-polylactic acid, D-polylactic acid, polyglycolic acid, and starch through a twin-screw extruder according to a certain ratio, and the extrusion temperature is 180°C to obtain a nucleating agent. Among them, The starch content is 3%, wherein the ratio of the L-polylactic acid, D-polylactic acid, talcum powder and polymethacrylate is 90:65:1.5:1;

[0040] Step 2: In parts by weight, 65 parts of semi-crystalline polylactic acid, 1.5 parts of polymer crystallization accelerator, 5 parts of nucleating agent, and 2 parts of plasticizer, the semi-crystalline polylactic acid is preferably semi-crystalline Poly L-lactic acid, stir evenly to obtain a mixture, mix 95 parts of the mixture and 6 parts of polymer crystallization accelerator in a ball mill, the mixing temperature is above 82°C, mix for 1 hour, and place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com