Injectable high-strength composite hydrogel based on colloidal particle-iPRF double network structure, and preparation method and application thereof

A technology of compounding hydrogels and colloidal particles, which is applied in the directions of inactive components of polymer compounds, prostheses, and liquid transportation, can solve the problems of short degradation period, limited regeneration potential, poor mechanical strength of materials, etc. volume increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

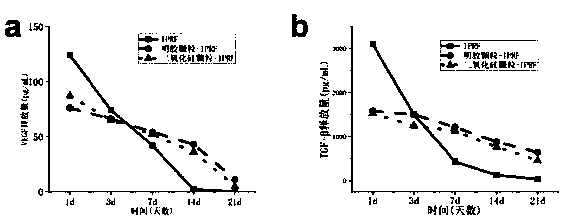

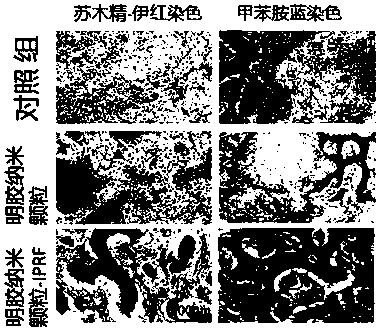

Examples

Embodiment 1

[0044] (1) Different sizes of silica and iprf

[0045] Commercially available silica nanoparticles with a particle size of 100,500 nm (purchased from Sigma Chemical Co., Ltd.) were used. The potential of the particles obtained by testing with a nanometer particle size analyzer is -30mV.

[0046] (2) Positive electrochemistry of silicon dioxide

[0047] Weigh 24g of purchased 100,500nm silica, disperse it into 600mL of ethanol, ultrasonically disperse for 15min, and prepare a 15mg / mL silica suspension. Place it in a water bath at 40°C, add 3 mL of silane coupling agent APTMS within 20 minutes using a syringe pump, and stir at 1000 rpm. Subsequently, the reaction was carried out at 40° C. for 5 h. After the reaction, ethanol (1 time), ethanol-water (1 time), and water (4 times) were used to centrifuge and then disperse the cleaning particles for 6 times to prepare positively charged silica nanoparticles. The potential of the particles obtained by testing with a nanometer par...

Embodiment 2

[0055] (1) Different proportions of silica

[0056] Commercially available silica nanoparticles with a particle size of 100,500 nm (purchased from Sigma Chemical Co., Ltd.) were used. The potential of the particles obtained by testing with a nanometer particle size analyzer is -30mV.

[0057] (2) Positive electrochemistry of silicon dioxide

[0058] Weigh 24g of purchased 100,500nm silicon dioxide, disperse it into 600mL of ethanol, ultrasonically disperse for 15min, and prepare a 15mg / mL silicon dioxide suspension. Place it in a water bath at 40°C, add 3 mL of silane coupling agent APTMS within 20 minutes using a syringe pump, and stir at 1000 rpm. Subsequently, the reaction was carried out at 40° C. for 5 h. After the reaction, ethanol (1 time), ethanol-water (1 time), and water (4 times) were used to centrifuge and redisperse the cleaning particles for 6 times to prepare positively charged silica nanoparticles. The potential of the particles obtained by testing with a n...

Embodiment 3

[0066] (1) Different sizes of silica and iprf

[0067] Commercially available silica nanoparticles with a particle size of 100,500 nm (purchased from Sigma Chemical Co., Ltd.) were used. The potential of the particles obtained by testing with a nanometer particle size analyzer is -30mV.

[0068] (2) Positive electrochemistry of silicon dioxide

[0069] Weigh 24g of purchased 100,500nm silicon dioxide, disperse it into 600mL of ethanol, ultrasonically disperse for 15min, and prepare a 15mg / mL silicon dioxide suspension. Place it in a water bath at 40°C, add 3 mL of silane coupling agent APTMS within 20 minutes using a syringe pump, and stir at 1000 rpm. Subsequently, the reaction was carried out at 40° C. for 5 h. After the reaction, ethanol (1 time), ethanol-water (1 time), and water (4 times) were used to centrifuge and redisperse the cleaning particles for 6 times to prepare positively charged silica nanoparticles. The potential of the particles obtained by testing with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com