Graphene-doped tin oxide-based lithium nanobattery anode material and preparation method

A tin oxide-based lithium and battery negative electrode technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as specific capacity decline, and achieve the effects of promoting the integrity of the eutectic phase, prolonging cycle life, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0025] A kind of graphene-doped tin oxide-based lithium nano-battery anode material implementation method of the present invention is as follows:

[0026] S1. A graphene oxide solution of 10-50 mg / ml is prepared by an oxidation exfoliation graphite method. Dissolve 10-25g SnCl in 100mL 10-50mg / ml graphene oxide distilled aqueous solution 4 ·5H 2 O, add AMP-95 (2-amino-2-methyl-1-propanol) dropwise while stirring until the pH value is 7-9, after standing and aging for 4-10 hours, wash with distilled water and ethanol 2-3 times, and then formulated into 100ml of the above ethanol gel containing graphene oxide;

[0027]S2. Put the gel into a 2L high-pressure reactor, fill it with 500ml of absolute ethanol, raise the temperature and pressure to 250-300°C, and the pressure is 7-9MPa. After stabilizing for 1-5 hours, release the pressure and release the fluid slowly , and then purging with nitrogen for 20-40min, take out the dry gel;

[0028] S3. Put the dried gel into a high-te...

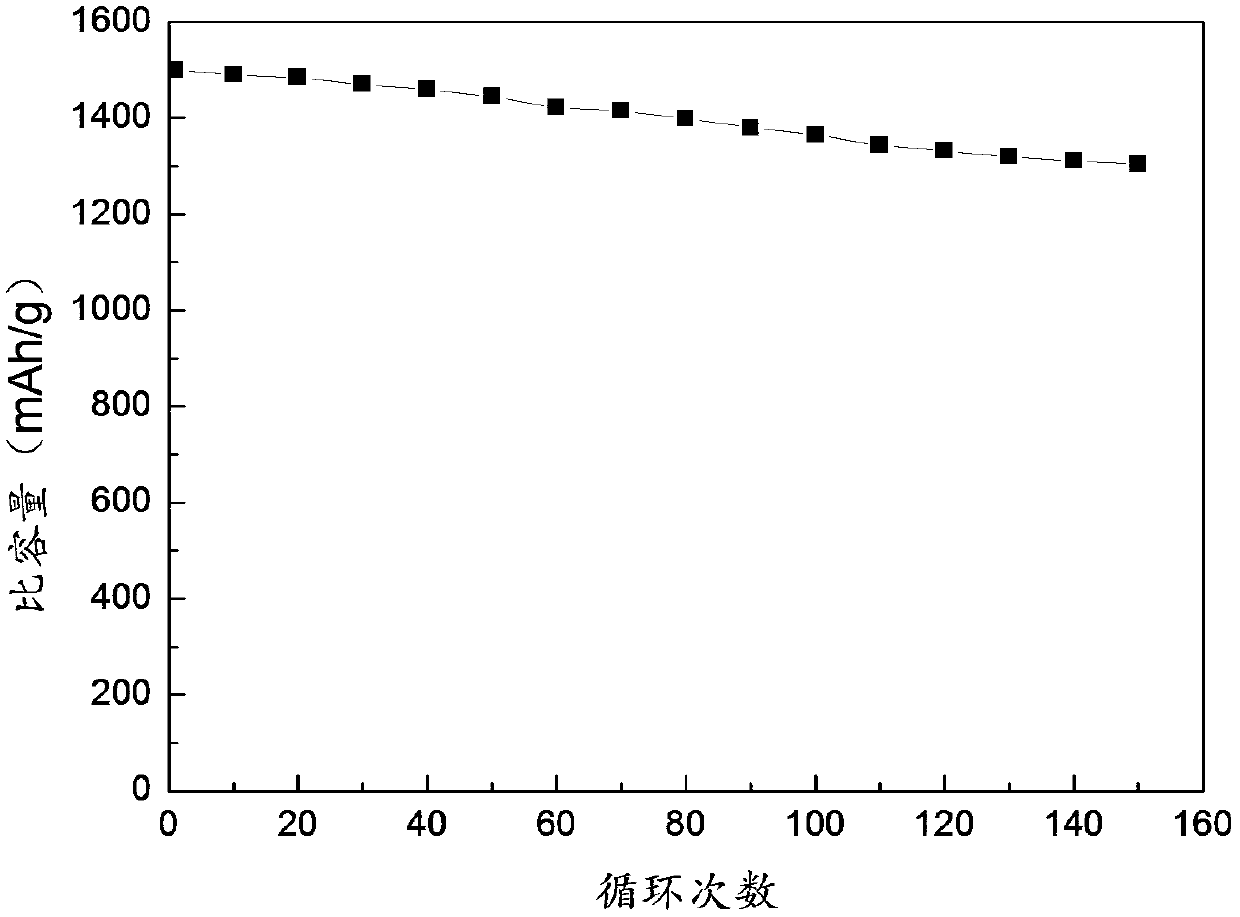

Embodiment 1

[0031] The preparation method of the tin oxide-based lithium nano battery negative electrode material doped with graphene in this embodiment comprises the following steps:

[0032] S1. Prepare a 20 mg / ml graphene oxide solution by using the oxidation-exfoliated graphite method. Dissolve 10 g of SnCl in 100 mL of graphene oxide distilled aqueous solution with a concentration of 20 mg / ml 4 ·5H 2 0, add AMP-95 (2-amino-2-methyl-1-propanol) dropwise while stirring until the pH value is 8, after standing and aging for 4 hours, wash 3 times with distilled water and ethanol respectively, and then Be mixed with the above-mentioned ethanol gel containing graphene oxide of 100ml;

[0033] S2. Put the gel into a 2L high-pressure reactor, fill it with 500ml of absolute ethanol, raise the temperature and pressure to 280°C, and the pressure is 7.5MPa. After stabilizing for 1 hour, release the pressure and slowly release the fluid, and then blow it with nitrogen. Sweep for 30min, take out...

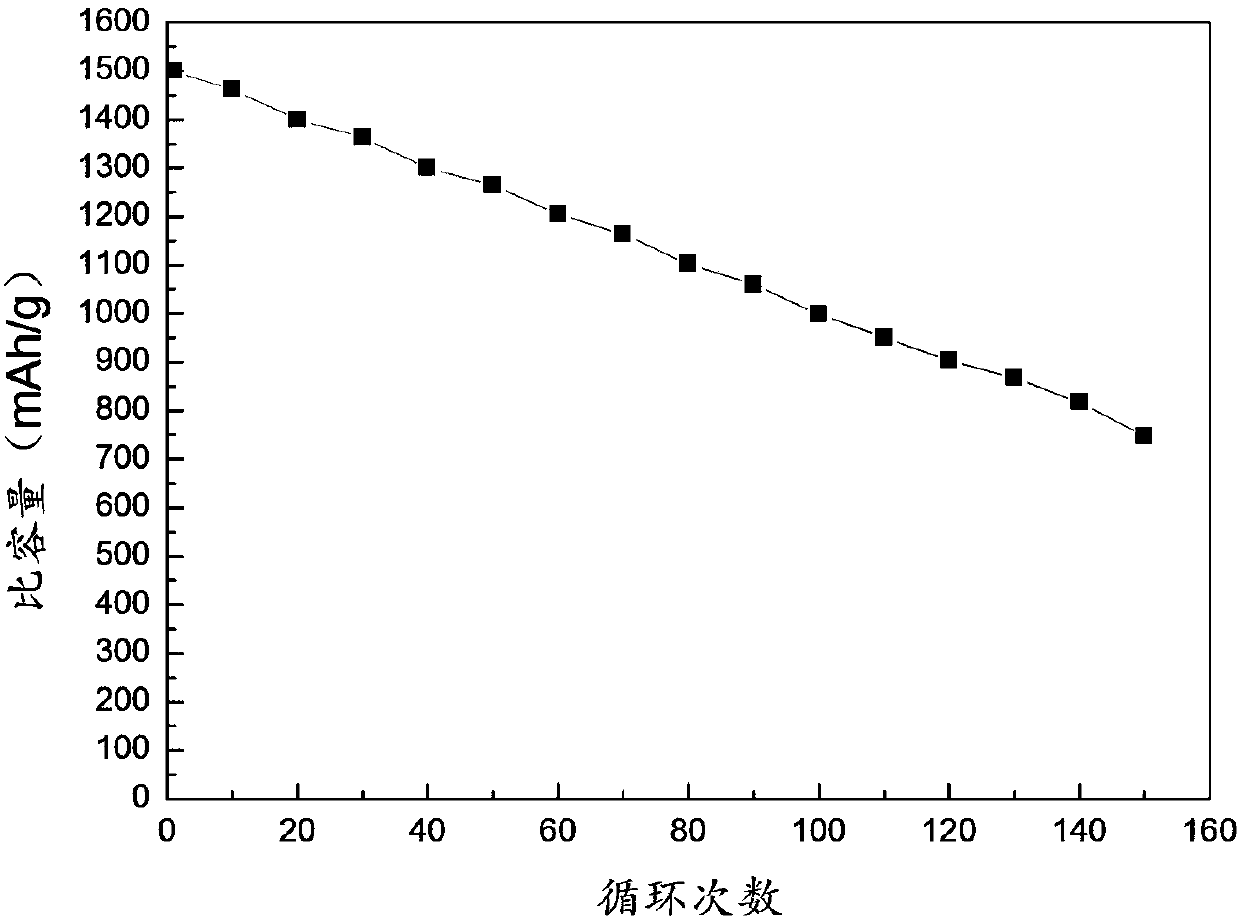

Embodiment 2

[0037] The preparation method of the tin oxide-based lithium nano battery negative electrode material doped with graphene in this embodiment comprises the following steps:

[0038] S1. A graphene oxide solution of 25 mg / ml was prepared by oxidizing and exfoliating graphite. Dissolve 10 g of SnCl in 100 mL of graphene oxide distilled aqueous solution with a concentration of 20 mg / ml 4 ·5H 2 0, add AMP-95 (2-amino-2-methyl-1-propanol) dropwise while stirring until the pH value is 8, after standing and aging for 4 hours, wash 3 times with distilled water and ethanol respectively, and then Be mixed with the above-mentioned ethanol gel containing graphene oxide of 100ml;

[0039] S2. Put the gel into a 2L high-pressure reaction kettle, fill it with 500ml of absolute ethanol, raise the temperature and pressure to 285°C, and the pressure is 8MPa. After stabilizing for 1 hour, release the pressure and slowly release the fluid, and then purge with nitrogen. 30min, take out the dry g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com