Preparation method of silicon dioxide material with hierarchical pore structure

A technology of silica and hierarchical pores, which is applied in the direction of silica, silicon oxide, chemical instruments and methods, etc., can solve the problems of complex synthesis methods of hierarchical porous structures and inability to prepare large-scale The effect of preparation production, high yield and simple preparation procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

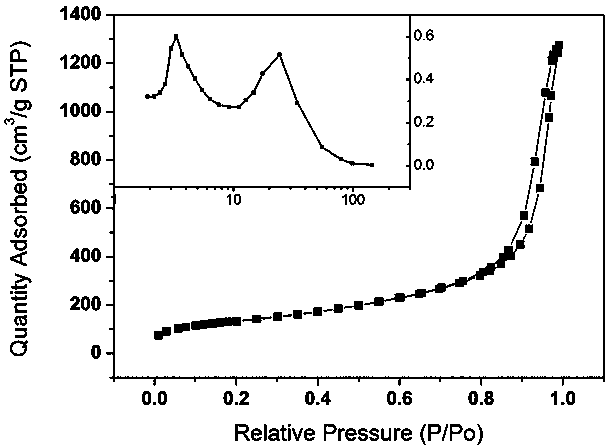

[0028] Weigh 100 mg of sodium salicylate and 1000 mg of cetyltrimethylammonium bromide, add 60 ml of deionized water, and stir at 60°C for 1 hour to form a homogeneous solution. Add 200 mg of triethanolamine to the above solution and continue to stir for 0.5 hours. Add 9 ml of tetraethyl orthosilicate and stir for 12 hours at a constant temperature in an oil bath at 60°C. After cooling to room temperature, centrifuge at 10,000 rpm for 10 minutes, collect the precipitate, wash the precipitate 3 times with ethanol; dry; the obtained solid is calcined at 600°C for 6 hours to obtain 2.113 g of a hierarchical pore structure with a particle size of 50 nm Dendritic silica material with a yield of 88.0%.

Embodiment 2

[0030] Weigh 500 mg of sodium salicylate and 1000 mg of cetyltrimethylammonium bromide, add 60 ml of deionized water, and stir at 60°C for 1 hour to form a homogeneous solution. Add 200 mg of triethanolamine to the above solution and continue to stir for 0.5 hours. Add 9 ml of tetraethyl orthosilicate and stir for 12 hours at a constant temperature in an oil bath at 60°C. After cooling to room temperature, centrifuge at 10,000 rpm for 10 minutes, collect the precipitate, wash the precipitate 3 times with ethanol; dry; the obtained solid is calcined at 600°C for 6 hours to obtain 2.169 g of a 300-nanometer particle with a hierarchical pore structure Dendritic silica material with a yield of 90.3%.

Embodiment 3

[0032] Weigh 1000 mg of sodium salicylate and 1000 mg of cetyltrimethylammonium bromide, add 60 ml of deionized water, and stir at 60°C for 1 hour to form a homogeneous solution. Add 200 mg of triethanolamine to the above solution and continue to stir for 0.5 hours. Add 9 ml of tetraethyl orthosilicate and stir for 12 hours at a constant temperature in an oil bath at 60°C. After cooling to room temperature, centrifuge at 10,000 rpm for 10 minutes, collect the precipitate, wash the precipitate 3 times with ethanol; dry; the obtained solid is calcined at 600°C for 6 hours to obtain 2.215 g of a hierarchical pore structure with a particle size of 500 nm Dendritic silica material with a yield of 92.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com