Machining equipment for key slot of platemaking roller plug head, and working method thereof

A technology of processing equipment and working methods, which is applied in the field of plate-making roller plug keyway processing equipment, can solve the problems that the manual grinding accuracy of keyways cannot be unified, and achieve the goals of improving manual grinding efficiency, facilitating grinding processing, and improving processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

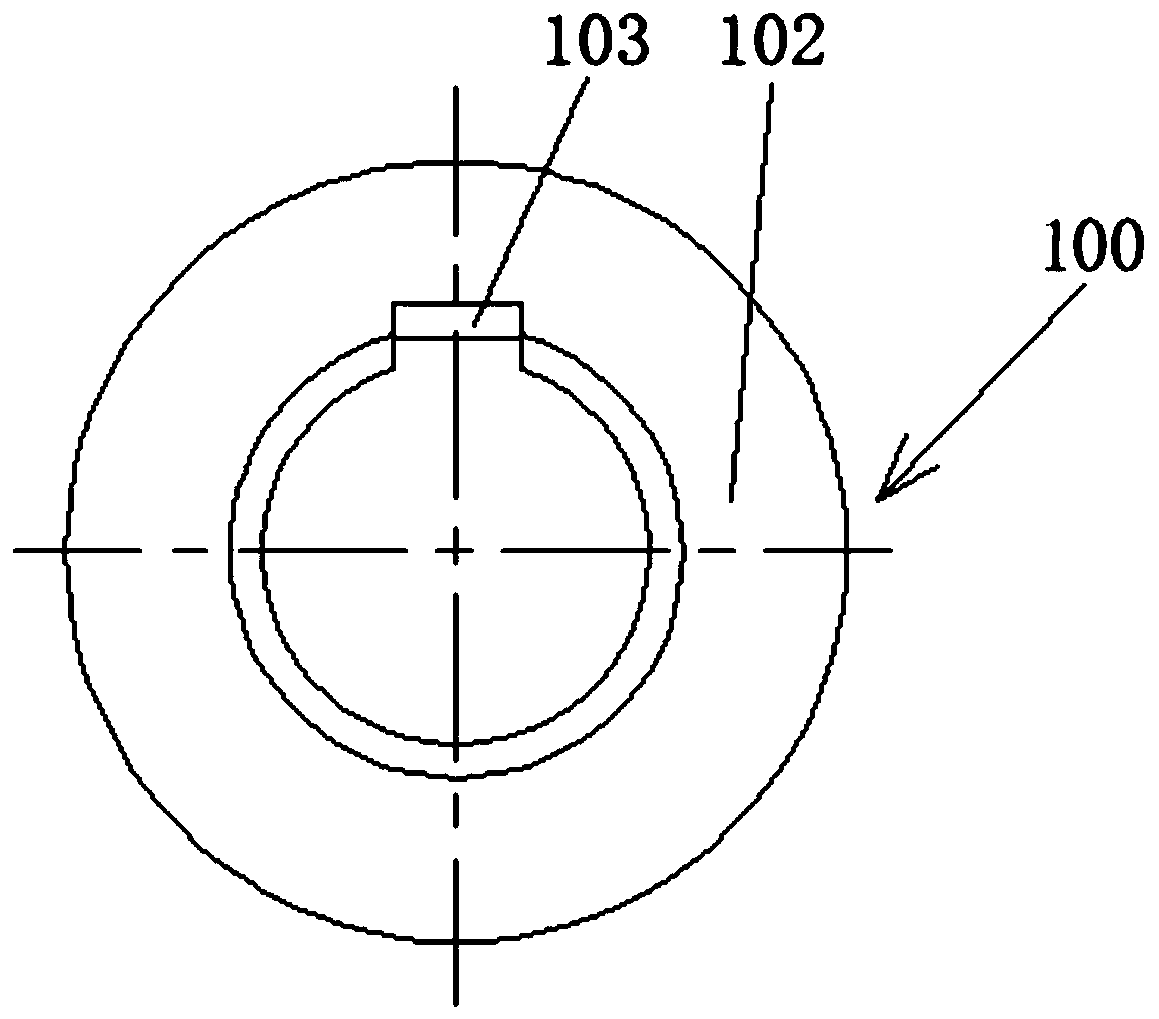

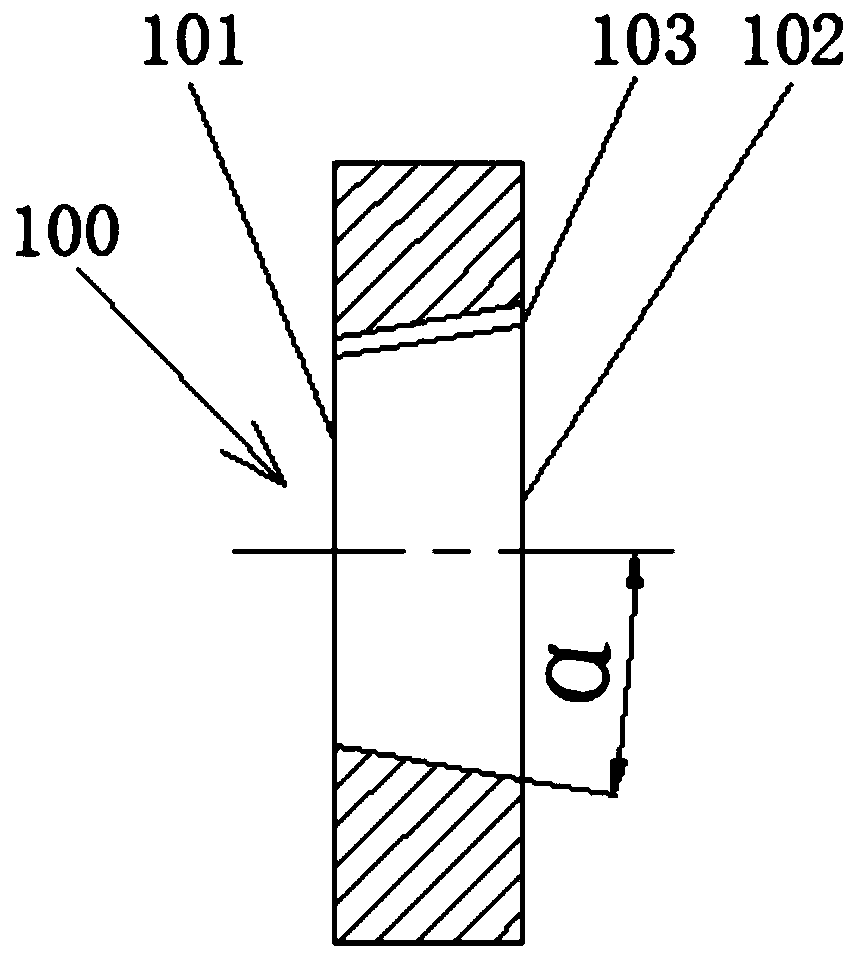

[0044] Such as Figure 1a with Figure 1b It shows a schematic diagram of the front view and a schematic diagram of the left view of the plate-making roller plug of the present invention according to an exemplary embodiment,

[0045] In this embodiment, the plate-making roller plug keyway processing equipment is characterized in that the plate-making roller plug 100 includes: a plug first surface 101, a plug second surface 102 and a keyway 103,

[0046] A through hole is formed between the first face 101 of the plug and the second face 102 of the plug, and the through hole extends from the first face 101 of the plug to the second face 102 of the plug in the shape of a bell mouth , and the single side of the bell mouth forms an angle α with the center line of the plate-making roller plug 100, the angle α is between 0-15°, preferably 10°, and the keyway 103 is along the first surface 101 of the plug Opening through the second face 102 of the plug, the keyway and the center line...

Embodiment 2

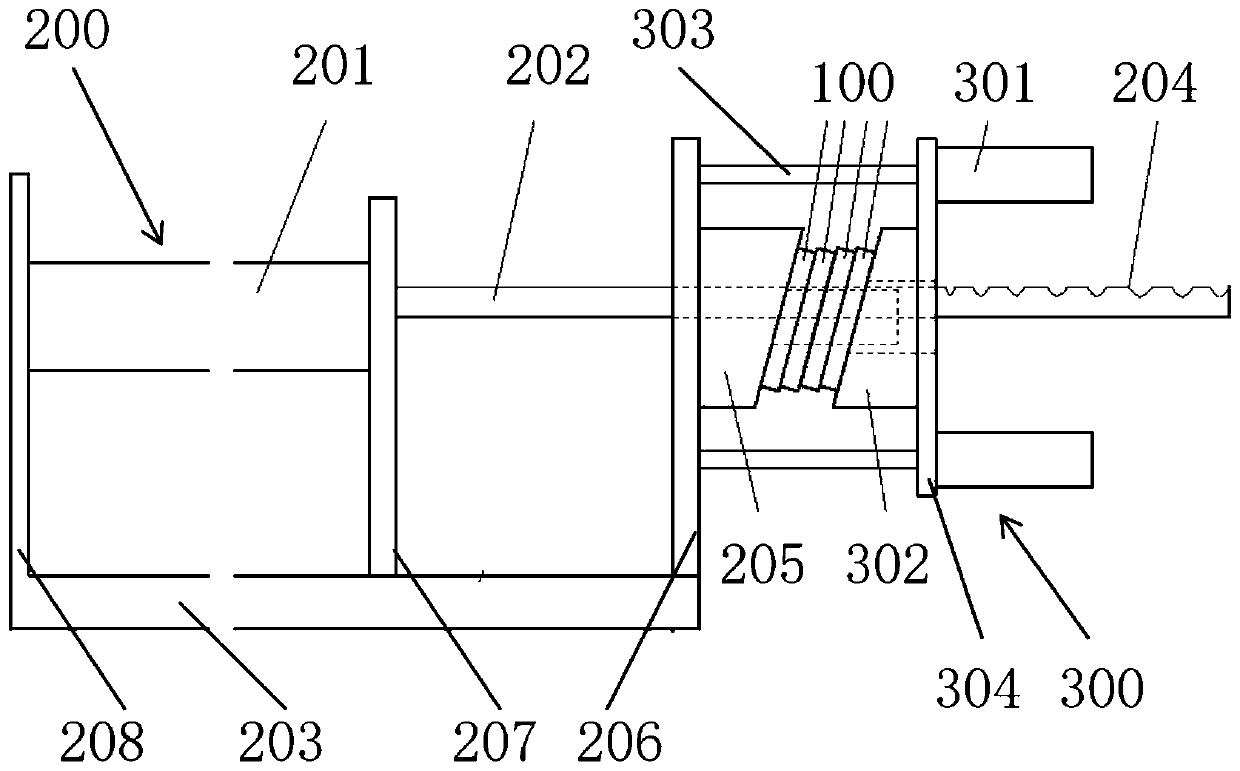

[0051] The present invention also relates to a working method of the plate-making roller plug keyway processing equipment, characterized in that the plate-making roller plug keyway processing equipment includes: a keyway processing part 200 and a keyway clamping part 300; the keyway processing part 200 It is used to process the keyway of the plate-making roller plug 100. The keyway clamping part 300 is used to clamp and fix the plate-making roller plug at the same time as the keyway processing part 200. The keyway processing part 200 includes: a first linear drive 201, the first driving rod 202, the base 203, the broach 204, the first clamping part 205, the first side plate 206, the second side plate 207 and the third side plate 208; the keyway clamping part 300 includes: the first Two linear drivers 301, a second clamping part 302, a second driving rod 303 and a fourth side plate 304; the plate-making roller plug 100 includes: a plug first face 101, a plug second face 102 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com