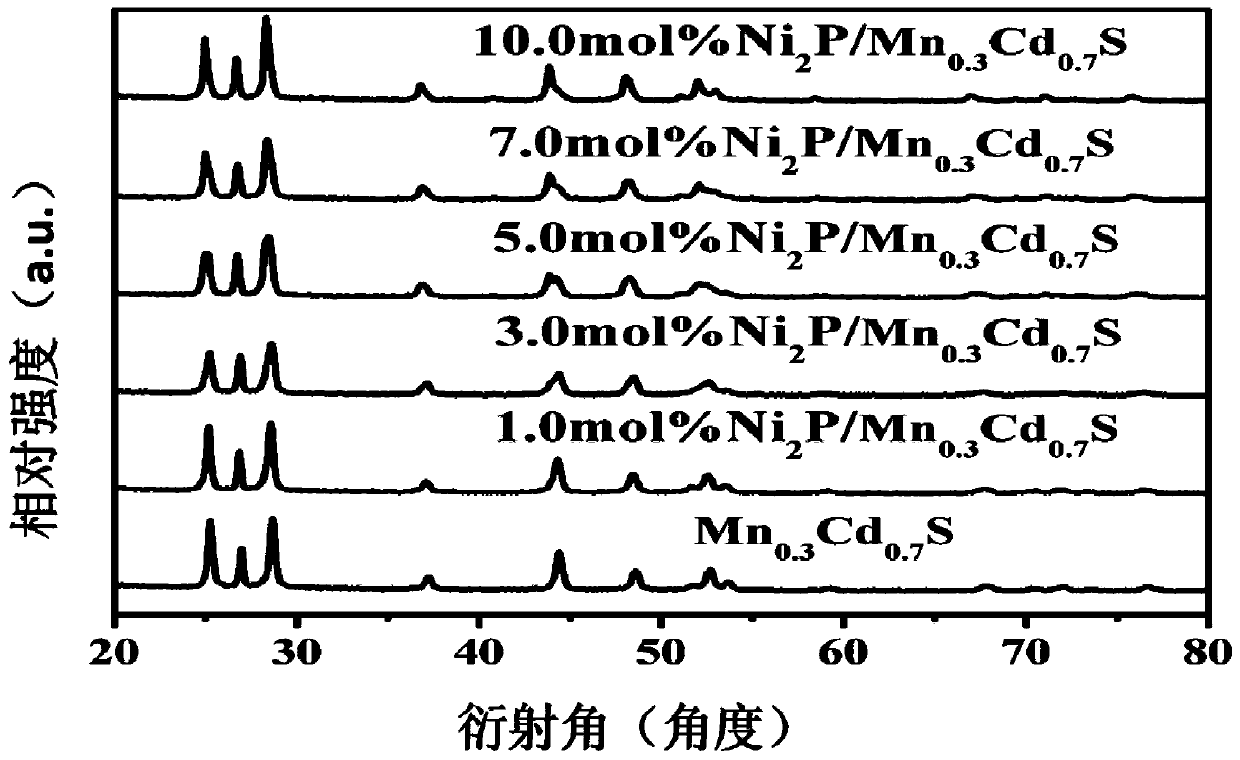

Ni2P/Mn0.3Cd0.7S photocatalytic water-decomposition composite catalyst and preparation method and application thereof

A composite catalyst, photocatalysis technology, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen/synthesis gas production, etc. problem, to achieve the effect of improving hydrogen production rate, low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of Ni 2 P / Mn 0.3 Cd 0.7 The preparation method of S photocatalytic water splitting composite catalyst, comprises the steps:

[0045] (1) Mix 5 g of commercial red phosphorus with 15 mL of organic solvent (ethylene glycol), put it into an agate jar, seal it, vacuumize it, and grind it under a protective atmosphere (argon atmosphere). The grinding time is 24 h, washing, drying in an argon atmosphere at 100°C for 10 h to obtain pretreated red phosphorus, the particle size of the pretreated red phosphorus is 1-3 μm;

[0046] (2) Add 500 mg of Mn 0.3 Cd 0.7 The S catalyst was added into an aqueous solution of ethanol (volume percent concentration: 33.3 vol%), stirred, the speed of the stirring treatment was 200 rpm, the time of the stirring treatment was 30 min, and then the ultrasonic treatment was performed, the frequency of the ultrasonic treatment was 25 KHz, and the ultrasonic treatment was performed. The treatment time is 1 h, so that Mn 0.3 Cd 0.7 The S ...

Embodiment 2

[0050] A kind of Ni 2 P / Mn 0.3 Cd 0.7 The preparation method of S photocatalytic water splitting composite catalyst, comprises the steps:

[0051] (1) Mix 5 g of commercial red phosphorus with 15 mL of organic solvent (ethylene glycol), put it into an agate jar, seal it, vacuumize it, and grind it under a protective atmosphere (argon atmosphere). The grinding time is 24 h, washing, drying in an argon atmosphere at 100°C for 10 h to obtain pretreated red phosphorus, the particle size of the pretreated red phosphorus is 1-3 μm;

[0052] (2) Add 500 mg of Mn 0.3 Cd 0.7 The S catalyst was added into an aqueous solution of ethanol (volume percent concentration: 33.3 vol%), stirred, the speed of the stirring treatment was 200 rpm, the time of the stirring treatment was 30 min, and then the ultrasonic treatment was performed, the frequency of the ultrasonic treatment was 25 KHz, and the ultrasonic treatment was performed. The treatment time is 1 h, so that Mn 0.3 Cd 0.7 The S ...

Embodiment 3

[0056] A kind of Ni 2 P / Mn 0.3 Cd 0.7 The preparation method of S photocatalytic water splitting composite catalyst, comprises the steps:

[0057] (1) Mix 5 g of commercial red phosphorus with 15 mL of organic solvent (ethylene glycol), put it into an agate jar, seal it, vacuumize it, and grind it under a protective atmosphere (argon atmosphere). The grinding time is 24 h, washing, drying in an argon atmosphere at 100°C for 10 h to obtain pretreated red phosphorus, the particle size of the pretreated red phosphorus is 1-3 μm;

[0058] (2) Add 500 mg of Mn 0.3 Cd 0.7 The S catalyst was added into an aqueous solution of ethanol (33.3vol% by volume), stirred, the rate of stirring was 200 rpm, the time of stirring was 30 min, and then ultrasonic treatment was performed, the frequency of ultrasonic treatment was 25 KHz, and the ultrasonic The treatment time is 1 h, so that Mn 0.3 Cd 0.7 The S catalyst is evenly dispersed to obtain a suspension;

[0059] (3) Mix 93 mg of NiC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com