A kind of austenitic stainless steel for preparing sporks and its manufacturing method and application

An austenitic stainless steel and manufacturing method technology, applied in the field of stainless steel, can solve the problems of limited production efficiency in the polishing process, prone to center delamination, and increased production costs, so as to save annealing and pickling operations, low grinding and polishing costs, The effect of high grinding processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

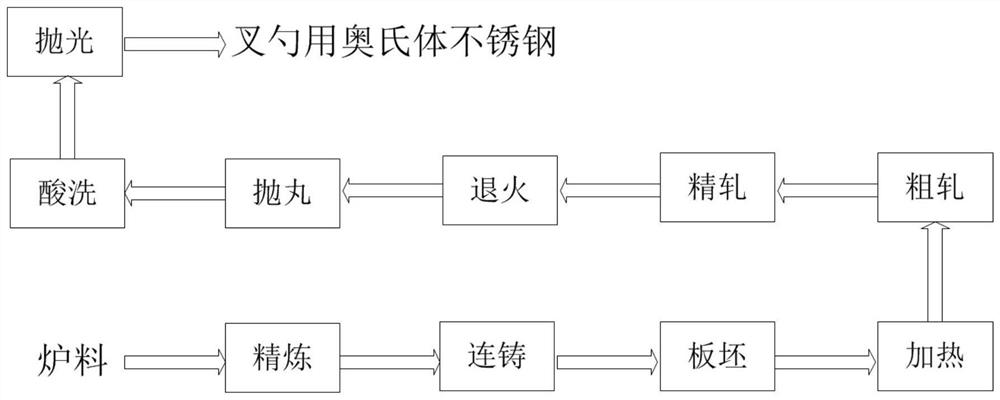

[0051] This embodiment provides a kind of manufacturing method for the austenitic stainless steel that is used to prepare spork and spoon, such as figure 1 As shown, the manufacturing method includes:

[0052] Furnace material: The raw material composition of the furnace used is: C: 0.05%, Si: 0.5%, Mn: 1.1%, P: 0.035%, S: 0.03%, Cr: 18.2%, Ni: 8.1%, Cu: 0.15%, N: 0.04%, and the balance of Fe; Md30: 7.32 ℃;

[0053]Refining: Feed the charge into the electric furnace for heating and then refining;

[0054] Continuous casting, the refined charge is continuously cast, wherein the molten steel flow rate is controlled to 2.5 tons / min through the stopper rod, the insertion depth of the nozzle is 120mm, and then the crystallizer liquid level fluctuation MLAC is controlled to 100%; the solidification end uses continuous casting light Reduction technology, the total reduction of continuous casting light pressure at the end of solidification is 3mm;

[0055] Continuous casting, heati...

Embodiment 2

[0062] This embodiment provides a method for manufacturing an austenitic stainless steel for preparing a spork, the manufacturing method comprising:

[0063] Furnace material: The raw material composition of the furnace used is: C: 0.06%, Si: 0.4%, Mn: 1.1%, P: 0.035%, S: 0.03%, Cr: 18.2%, Ni: 8.03%, Cu: 0.35%, N: 0.045%, and the rest of Fe; Md30: -4°C;

[0064] Refining: Feed the charge into the electric furnace for heating and then refining;

[0065] Continuous casting, heating, rough rolling, finishing rolling (including layer cooling and coiling), and annealing are performed sequentially on the refined charge;

[0066] Continuous casting, the refined charge is continuously cast, wherein the molten steel flow rate is controlled to 2.7 tons / min through the stopper rod, the insertion depth of the nozzle is 130mm, and the crystallizer liquid level fluctuation MLAC is controlled to 100%; the solidification end is controlled by continuous casting light Reduction technology, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com