Environment-friendly mold release agent and preparation method thereof

A release agent, an environmentally friendly technology, applied in the field of environmentally friendly release agents and their preparation, can solve the problems of waste of raw materials, easy access to pouring fluid, and reduced strength of finished products, so as to reduce the contact area, ensure the strength of finished products, and prevent excessive outflow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

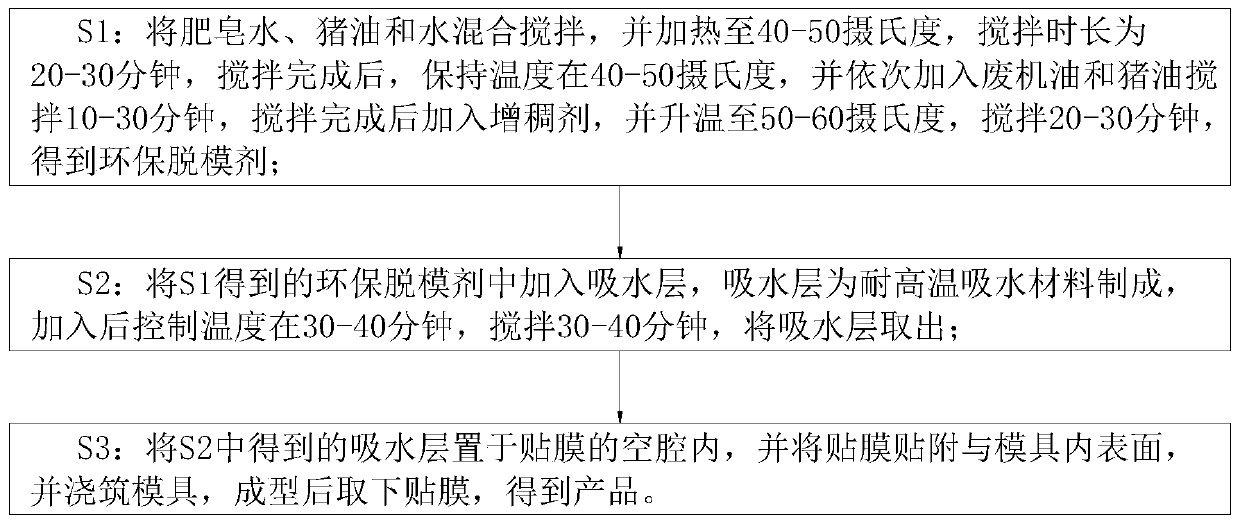

Method used

Image

Examples

Embodiment approach

[0029] As an embodiment of the present invention, the thickener is alkali-resistant thickening powder; the water is distilled water; the soapy water is a solution obtained by mixing laundry soap and water in a mass ratio of 1:3, and the soapy water After defoaming treatment.

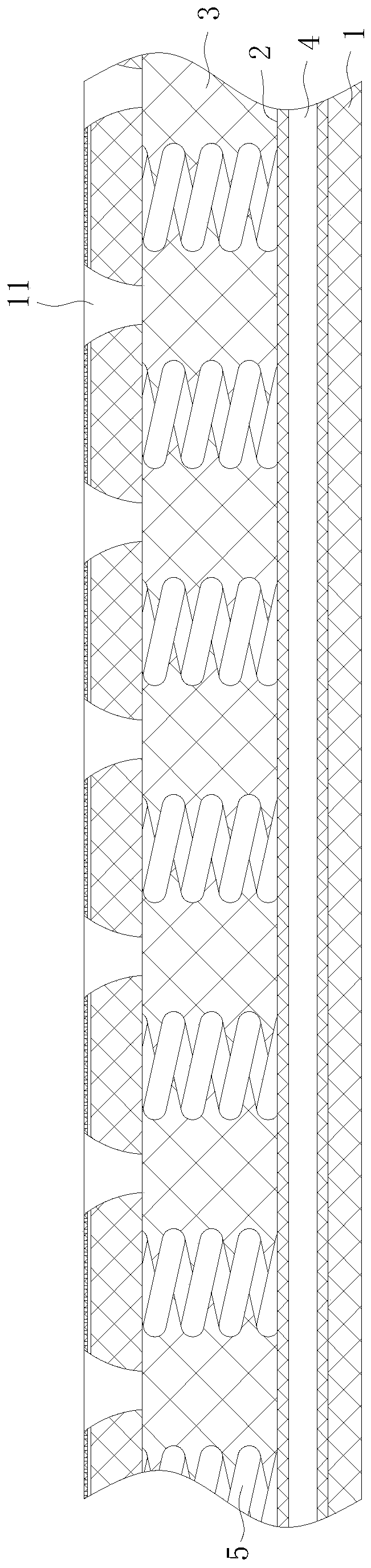

[0030] As an embodiment of the present invention, the film used in S3 wraps the membrane body 1; the membrane body 1 is provided with a cavity 2; a water-absorbing layer 3 is placed in the cavity 2; the membrane body 1- The side surface is designed with rough surface, which can be adhered to the surface of the mold by high temperature resistant glue; the side of the film body 1 opposite to the surface adhered to the mold is provided with evenly arranged through holes 11; the inner wall of the through hole 11 is arc-shaped design, and the through hole 11 communicates with the cavity 2; the membrane body 1 is provided with uniformly arranged micropores on the surface of the through hole 11; each of the mic...

Embodiment 1

[0038] 10-30 parts of waste engine oil, 2-6 parts of soapy water, 2-6 parts of thickener, 3-6 parts of lard and the remaining water are used to produce finished products according to the method provided by the invention;

Embodiment 2

[0040] 10-30 parts of waste engine oil, 2-6 parts of soapy water, 2-6 parts of thickener, 3-6 parts of lard and the remaining water are directly applied to the surface of the mold to produce finished products;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com