Non-fluorosilicon supercritical carbon dioxide fluid tackifier, preparation method and application thereof

A carbon dioxide and supercritical technology, applied in the direction of chemical instruments and methods, bulk chemical production, drilling compositions, etc., can solve the problems of no economic value, high price, weak non-covalent interaction, etc., and achieve beneficial Environmental protection, increase drilling speed, and reduce the effect of greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

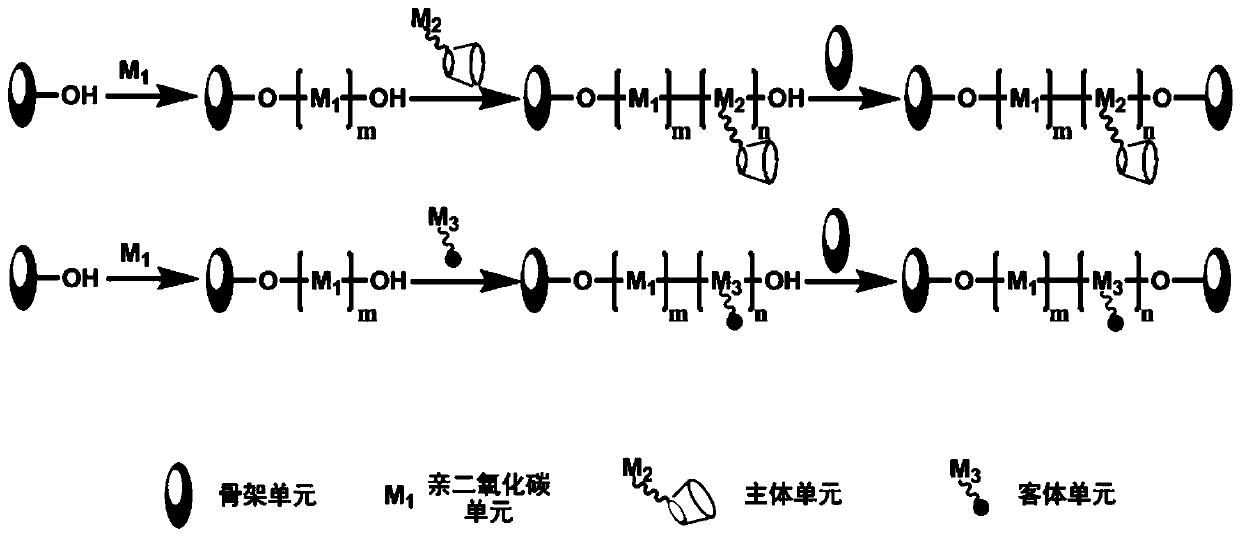

[0054] Aiming at the problems existing in the prior art, the present invention provides a non-fluorosilicone supercritical carbon dioxide fluid viscosifier, its preparation method and application. figure 1 to attach Figure 14 The present invention is described in detail.

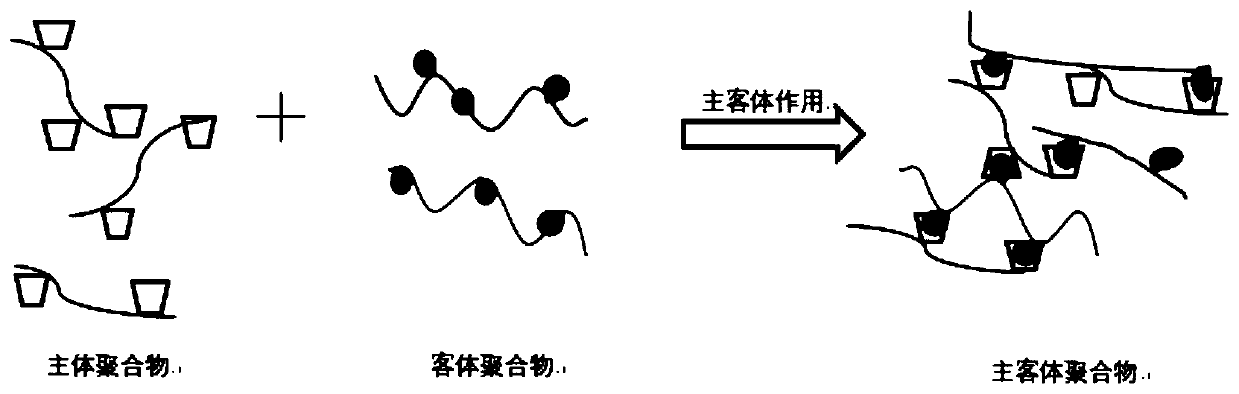

[0055] The non-fluorosilicone supercritical carbon dioxide fluid viscosity enhancer provided by the embodiment of the present invention uses cyclodextrin and its derivatives as the host compound, and uses alkyl, aryl or ether compounds as the guest compound. The molar ratio of the host compound to the guest compound is 1:1.

[0056] Such as figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com