Efficient fireproof heat-insulating coating layer for special compartment or shelter

A technology of thermal insulation coating and cabin, applied in fire-resistant coatings, coatings, epoxy resin coatings, etc., can solve the problem that fire-resistant coatings and thermal insulation coatings are not suitable for special vehicles or shelters, etc., and achieve good rust prevention. Anti-corrosion performance, good fire and heat insulation effect, small porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

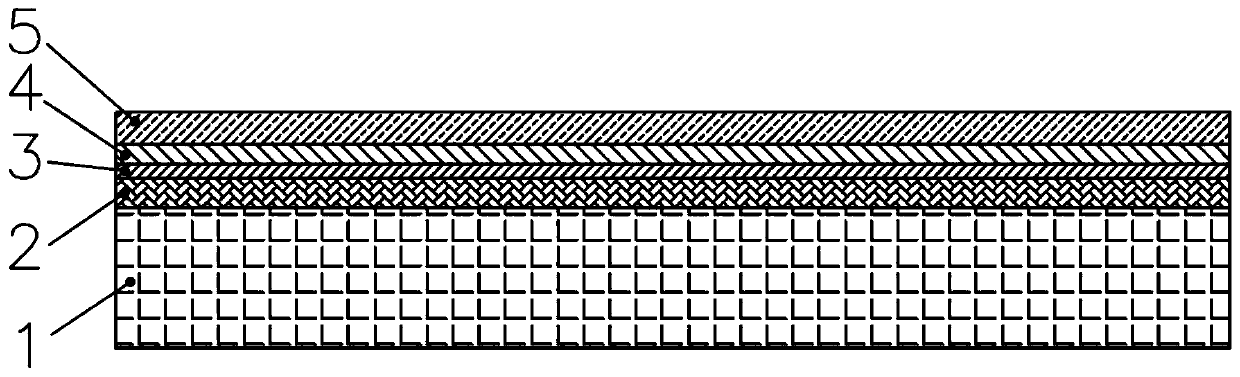

[0026] Such as figure 1 As shown, a high-efficiency fireproof and heat-insulating coating for a special carriage or shelter is coated on the outer wall of the carriage or shelter steel plate 1. The rust matrix layer 2 has a thickness of 60 μm, the heat insulation functional layer 3 has a thickness of 1 mm, the anti-burning functional layer 4 has a thickness of 0.8 mm, and the protective topcoat layer 5 has a thickness of 60 μm;

[0027] The heat-insulating functional layer 3 is composed of a film-forming substance a, a filler with low thermal conductivity, and a functional auxiliary agent, and its mass ratio is 18:29:1; the anti-burning functional layer 4 is composed of a film-forming substance b, a dehydrating agent, and a forming agent. Carbon agent, blowing agent composition, its mass ratio is 2:5:2.5:1; Wherein, film former a is silicone modified epoxy resin; Low thermal conductivity filler is silica airgel, six whisker The mixture of potassium titanate and ceramic hollow...

Embodiment 2

[0032] Such as figure 1 As shown, a high-efficiency fireproof and heat-insulating coating for a special carriage or shelter is coated on the outer wall of the carriage or shelter steel plate 1. The rust matrix layer 2 has a thickness of 80 μm, the heat insulation functional layer 3 has a thickness of 1.3 mm, the anti-burning functional layer 4 has a thickness of 1.5 mm, and the protective topcoat layer 5 has a thickness of 80 μm;

[0033]The heat-insulating functional layer 3 is composed of a film-forming material a, a low thermal conductivity filler, and a functional auxiliary agent in a mass ratio of 22:31:1; the anti-burning functional layer 4 is composed of a film-forming material b, a dehydrating agent, and a forming agent Carbon agent, blowing agent composition, its mass ratio is 3: 7: 3.5: 3; Wherein, film former a is silicone modified epoxy resin; The mixture of potassium titanate and ceramic hollow microspheres, the mass ratio is 5:3:4; the functional additive is a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com