Inorganic nano antibacterial hard PVC (polyvinyl chloride) and preparation method thereof

An inorganic nano and nano technology, applied in the field of antibacterial plastics, can solve the problems of poor antibacterial performance, small effective specific surface area, decomposition failure, etc., achieve remarkable bactericidal and antibacterial effects, ensure antibacterial and antibacterial ability, and improve antibacterial and antibacterial ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

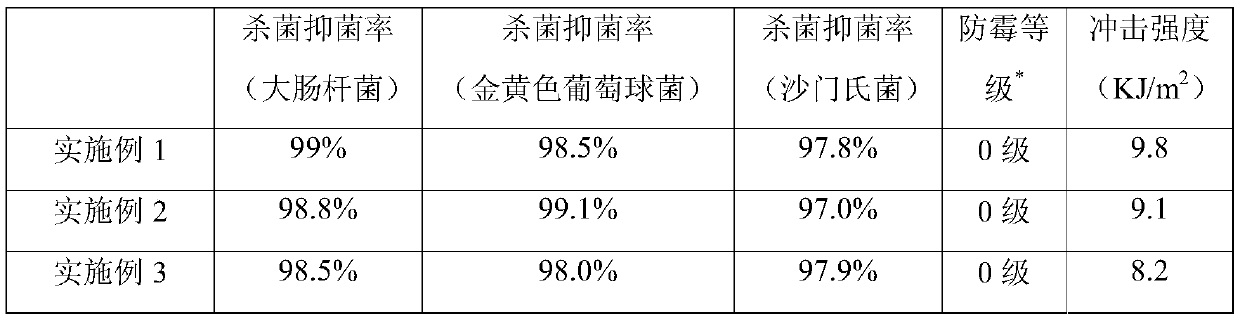

Examples

Embodiment 1

[0032] In parts by mass, the raw material formula of the inorganic nano antibacterial hard PVC of the present embodiment is as follows:

[0033] Rigid polyvinyl chloride (brand: UE508, Dongguan Feihua Plastic Co., Ltd.) 55 parts;

[0034] Inorganic non-metallic nanofillers (nano-SiO 2 , Brand: VK-SP30, Xuancheng Jingrui New Material Co., Ltd., particle size: 30nm) 15 parts;

[0035] Heat stabilizer (rare earth stabilizer, brand: 85795, Jinan Baijin Chemical Technology Co., Ltd.) 5 parts;

[0036] Coupling agent (silane coupling agent, brand: GF95, Shenzhen Huicheng Plastic Auxiliary Chemical Co., Ltd.) 13 parts;

[0037] Antioxidant (brand: 1076, Dongguan Kangjin New Material Technology Co., Ltd.) 7 parts;

[0038] UV absorber (brand: RQT-X-1, Henan Ruiqite Chemical Co., Ltd.) 5 parts;

[0039] During preparation, hard polyvinyl chloride, nano-SiO 2 Fillers, heat stabilizers, silane coupling agents, antioxidants, and ultraviolet absorbers are weighed according to the mass...

Embodiment 2

[0041] The difference from Example 1 is that in the raw material formula of this example, nano-ZnO is used as the inorganic non-metallic nano-filler, and other types of coupling agents and different proportions are selected.

[0042] In parts by mass, the raw material formula of inorganic nano antibacterial hard PVC is as follows:

[0043] Rigid polyvinyl chloride (brand: UE508, Dongguan Feihua Plastic Co., Ltd.) 60 parts;

[0044] Inorganic non-metallic nano-filler (nano-ZnO filler, Xuancheng Jingrui New Material Co., Ltd., particle size: 50nm) 10 parts;

[0045] Heat stabilizer (rare earth stabilizer, brand: 85795, Jinan Baijin Chemical Technology Co., Ltd.) 6 parts;

[0046] Coupling agent (aluminate coupling agent, brand: DL-411, Fuzhou Yuanke New Fine Materials Co., Ltd.) 10 parts;

[0047] Antioxidant (brand: 1076, Dongguan Kangjin New Material Technology Co., Ltd.) 8 parts;

[0048] UV absorber (brand: RQT-X-1, Henan Ruiqite Chemical Co., Ltd.) 6 parts;

[0049] Dur...

Embodiment 3

[0051] The difference with Example 1 is: adopt nano-TiO in the raw material formula of this example 2 As an inorganic non-metallic nano-filler, other types of coupling agents and different proportions are selected.

[0052] In parts by mass, the raw material formula of inorganic nano antibacterial hard PVC is as follows:

[0053] Rigid polyvinyl chloride (brand: UE508, Dongguan Feihua Plastic Co., Ltd.) 65 parts;

[0054] Inorganic non-metallic nanofillers (nano TiO 2 Filler, grade: 5484WJ, Nanjing Hongde Nano Material Co., Ltd., particle size: 20-50nm) 5 parts;

[0055] Heat stabilizer (rare earth stabilizer, brand: 85795, Jinan Baijin Chemical Technology Co., Ltd.) 8 parts;

[0056] Coupling agent (titanate coupling agent, brand: 201, Dongguan Shanyi Plastic Chemical Co., Ltd.) 5 parts;

[0057] Antioxidant (brand: 1076, Dongguan Kangjin New Material Technology Co., Ltd.) 9 parts;

[0058] 8 parts of ultraviolet absorber (brand: RQT-X-1, Henan Ruiqite Chemical Co., Ltd....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com