Polypropylene powder product for selective laser sintering and preparation method of polypropylene powder product

A technology of laser sintering and polypropylene, which is applied in the field of polymer material science, can solve problems such as the inability to achieve density reduction, material weight reduction, easy crushing, and automobile safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] A method for preparing a polypropylene powder product for selective laser sintering, comprising the following steps:

[0078] (a) Add polypropylene, elastomer and compatibilizer into the high-speed mixer, then add antioxidant and other additives, stir evenly, put them into the twin-screw feeding bin, use twin-screw extrusion to melt and mix evenly, and then make grain dry;

[0079] (b) Cooling the plastic particles obtained in step (a) with liquid nitrogen and then pulverizing them at low temperature to obtain plastic powder, the particle size of the powder is D10=10-40 μm, D50=50-90 μm, D98=100-150 μm;

[0080] (c) Add hollow glass microspheres to a high-speed mixer, then add a coupling agent and stir evenly, add the plastic powder and flow aid obtained in step (b), and stir evenly again to finally obtain the selectivity described in the present invention Polypropylene powder for laser sintering.

[0081] In the following examples, a laser particle size analyzer (M...

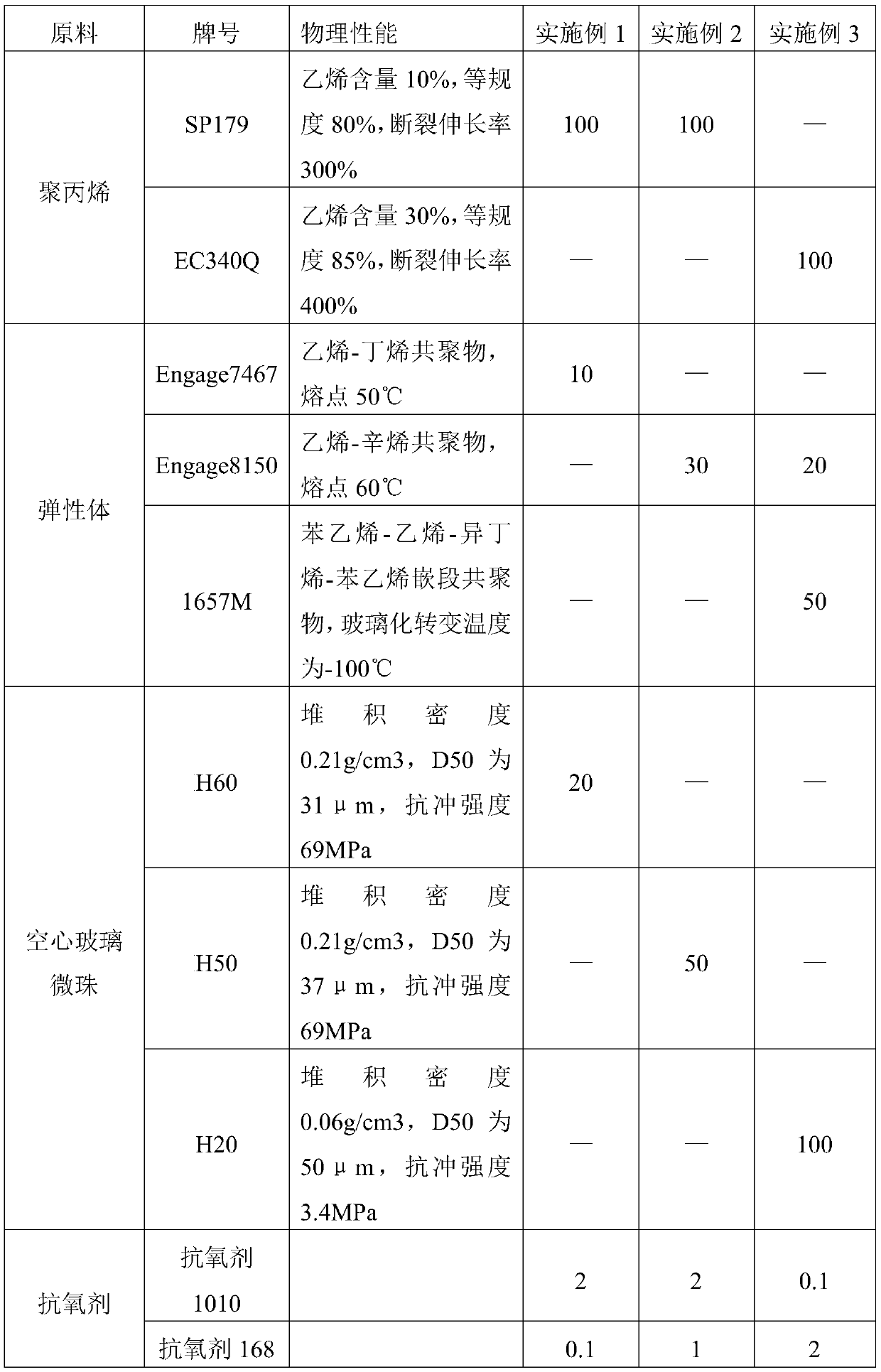

Embodiment 1-3

[0083] According to the composition of each component in Example 1-3, the polypropylene powder product was prepared according to the above-mentioned preparation method, and the hollow glass microspheres were purchased from Zhongke Yali Company. The polypropylene powder obtained in Examples 1-3 has a narrow particle size distribution, good fluidity, can well complete selective laser sintering, and the part does not warp and deform, and the density of the obtained part is far lower than that of the polypropylene resin (0.90 g / cm 3 ), high tensile properties, good toughness, and can be well applied.

[0084]

[0085]

[0086]

Embodiment 4-6

[0088]

[0089]

[0090]

[0091] According to the composition of each component in Example 4-6, the polypropylene powder product was prepared according to the above-mentioned preparation method, and the hollow glass microspheres were purchased from Zhongke Yali Company. The polypropylene powder particle size distribution obtained in embodiment 4-6 is narrow, fluidity is good, can finish selective laser sintering well, and warping deformation does not occur in the part, and the obtained part density is far lower than the polypropylene resin density (0.90 g / cm 3 ), high tensile properties, good toughness, and can be well applied.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com