Preparation method of microporous polymethacrylimide foaming agent

A technology of polymethacrylimide and polyether methacrylate diester, which is applied in the field of preparation of microporous polymethacrylimide foam, can solve the problem of low elongation at toughness and uniform fine cells and micropores Poor resistance and other problems, to achieve the effect of increased tensile modulus, good compatibility, and small cell size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

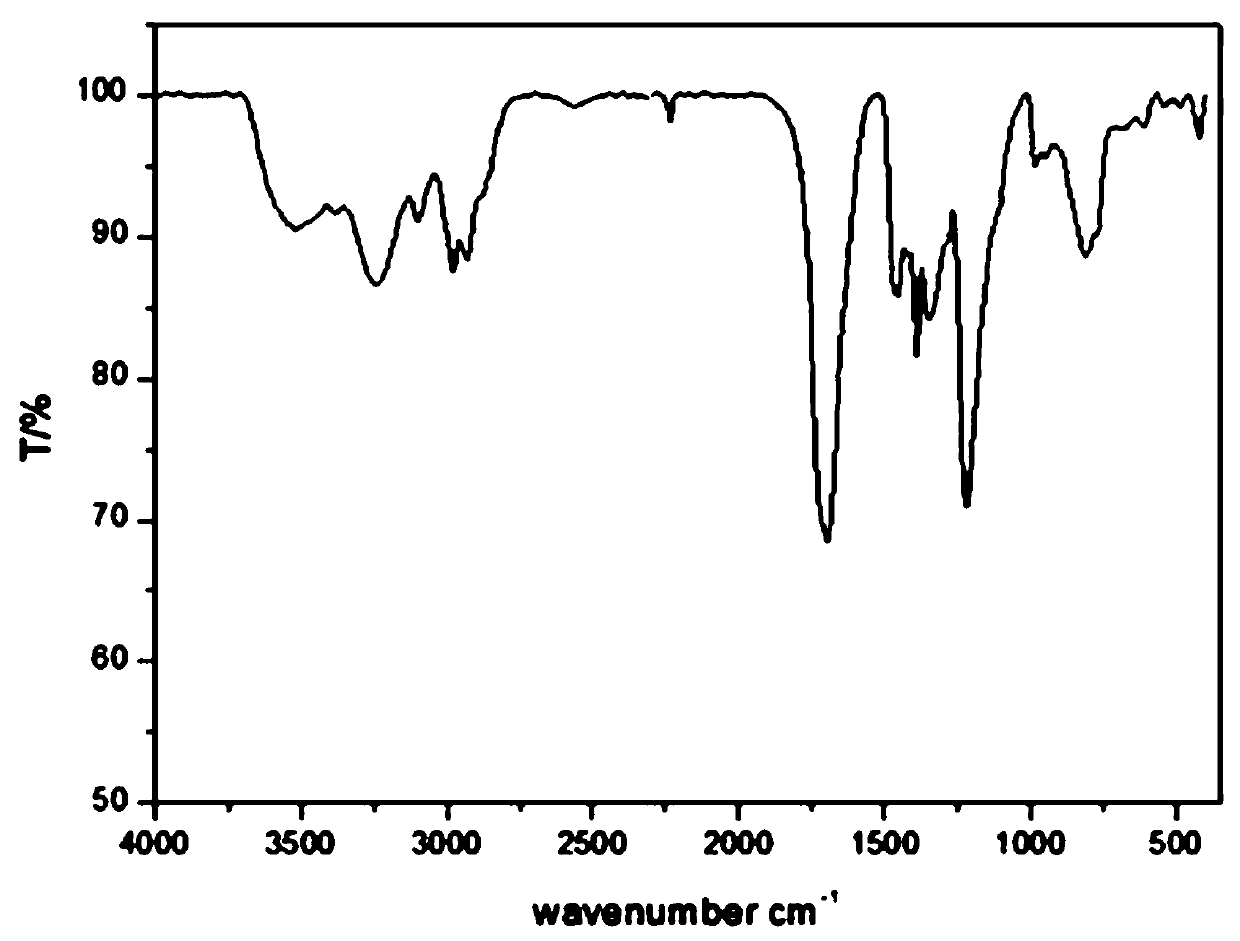

Image

Examples

Embodiment 1

[0026] A preparation method of microporous polymethacrylimide foam is prepared according to the following scheme:

[0027] A preparation method of microporous polymethacrylimide foam is prepared according to the following scheme:

[0028] According to the number of parts by mass, 55 parts of (meth)acrylonitrile, 35 parts of (meth)acrylic acid, 5 parts of polyether methacrylate diester, 3 parts of new microcellular foaming agent, 0.2 part of initiator Agent, 0.3 parts of nucleating agent, 1 part of crosslinking agent were added to the reaction kettle, under the protection of nitrogen, the temperature was raised to 35°C, stirred and reacted for 28 hours, then heated to 80°C, and continued to react for 10 hours to obtain a microporous polyformaldehyde The base acrylimide plastic plate is crushed and subjected to an in-mold foaming process to obtain a product, which is then cut and tested.

[0029] The in-mold foaming process is pre-foaming and rapid re-foaming, comprising the fo...

Embodiment 2

[0039] A preparation method of microporous polymethacrylimide foam is prepared according to the following scheme:

[0040] A preparation method of microporous polymethacrylimide foam is prepared according to the following scheme:

[0041] According to the number of parts by mass, 30 parts of (meth)acrylonitrile, 25 parts of (meth)acrylic acid, 1 part of polyether methacrylic diester, 0.5 part of new microcellular foaming agent, 0.01 part of initiator agent, 0.1 part of nucleating agent, 0.1 part of cross-linking agent were added to the reactor, under the protection of nitrogen, the temperature was raised to 30°C, stirred and reacted for 24 hours, then heated to 70°C, and continued to react for 5 hours to obtain a microporous polyformaldehyde The base acrylimide plastic plate is crushed and subjected to an in-mold foaming process to obtain a product, which is then cut and tested.

[0042] The in-mold foaming process is pre-foaming and rapid re-foaming, comprising the following...

Embodiment 3

[0052] A preparation method of microporous polymethacrylimide foam is prepared according to the following scheme:

[0053] According to the number of parts by mass, 65 parts of (meth)acrylonitrile, 70 parts of (meth)acrylic acid, 30 parts of polyether methacrylate diester, 10 parts of new microcellular foaming agent, 2.5 parts of initiator agent, 0.5 parts of nucleating agent, 3 parts of cross-linking agent were added to the reaction kettle, under the protection of nitrogen, the temperature was raised to 40°C, stirred and reacted for 36 hours, then heated to 95°C, and continued to react for 15 hours to obtain microporous polyformaldehyde The base acrylimide plastic plate is crushed and subjected to an in-mold foaming process to obtain a product, which is then cut and tested.

[0054] The in-mold foaming process is pre-foaming and rapid re-foaming, comprising the following steps:

[0055] The obtained polymethacrylimide particles are heated to a pre-expansion temperature of 27...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com