Premixed polyether for ocean buoys, polyurethane raw material composition, polyurethane foam and preparation method of polyurethane foam

A polyurethane foam and raw material composition technology, applied in the field of polyurethane, can solve the problems of low rigidity and strength of FRP, attenuation of FRP strength, insufficient rigidity, etc., and achieve the effect of light weight, excellent waterproof performance, and insensitivity to humidity and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

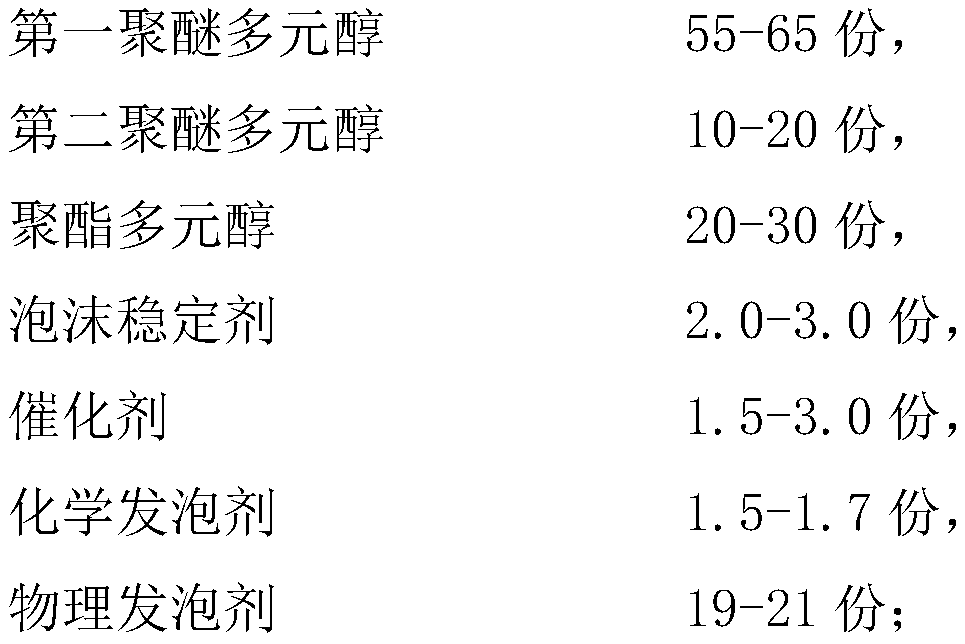

[0068] The parts by weight of the raw material composition of combined polyether and each component of isocyanate in embodiment 1-3 are specifically as shown in table 1:

[0069] Table 1 Combination of polyether and isocyanate components by weight.

[0070] Raw materials (Part A and Part B) Example 1 Example 2 Example 3 Example 4 Example 5 Polyether polyol NJ-6249 45 50 55 50 55 Polyether polyol NJ-8206H 30 35 25 25 30 Polyester polyol PEB-175 25 15 20 25 15 Foam stabilizer M-88608 2 2.5 2.5 2.5 3 pentamethyldiethylenetriamine 0.5 0.5 0.55 0.6 0.55 N, N-dimethylcyclohexylamine 1.0 1.0 0.9 0.7 0.8 N, N-dimethylbenzylamine 1.1 1.0 1.1 1.1 1.2 BX405 0.9 1.0 0.8 0.8 0.7 Deionized water 1.5 1.55 1.6 1.65 1.7 Cyclopentane 21 19 20 21 19 Combined polyether total components 128 125.55 127.45 129.35 126.95 Isocyanate PM200 153.6 150.66 152.94 155.22 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com