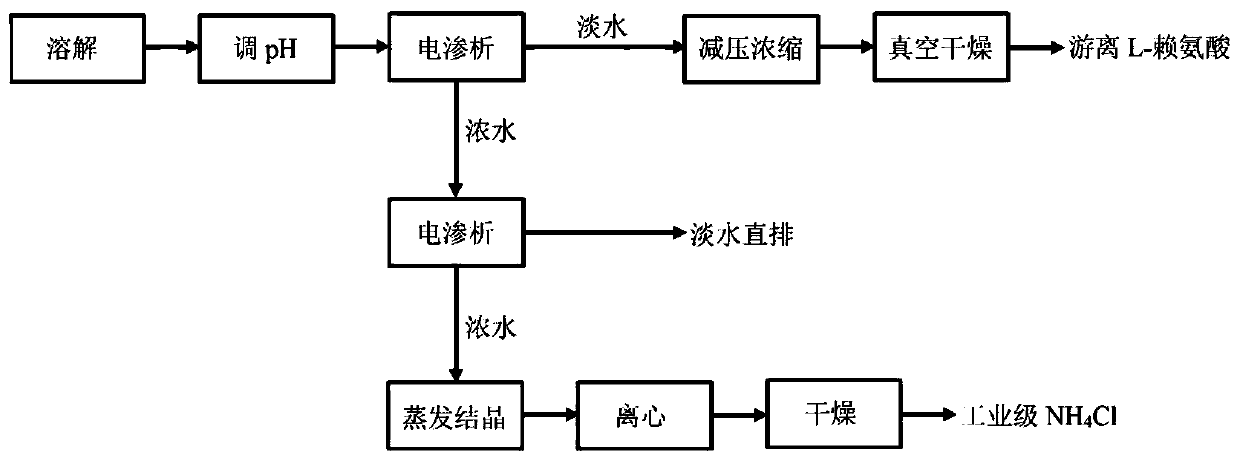

Method for extracting free L-lysine from ammonia water eluate by membrane method

A technology of lysine and eluent, which is applied in the field of free L-lysine purification, can solve the problems of high energy consumption and large amount of wastewater, and achieve reduced energy consumption and operating costs, long life, reduced water consumption and The effect of water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 183g of L-lysine hydrochloride and dissolve it in 175g of 20% ammonia water. After fully reacting, add pure water to 1000g to simulate the eluent of ammonia water. At this time, the concentration of free L-lysine is 14.6%. 4 The Cl concentration was 5.85%, and the pH was 9.89. Alloy membrane electrodialysis device (effective membrane area is 0.055m 2 ) extract the method for L-lysine in the ammonia eluent, comprise the steps:

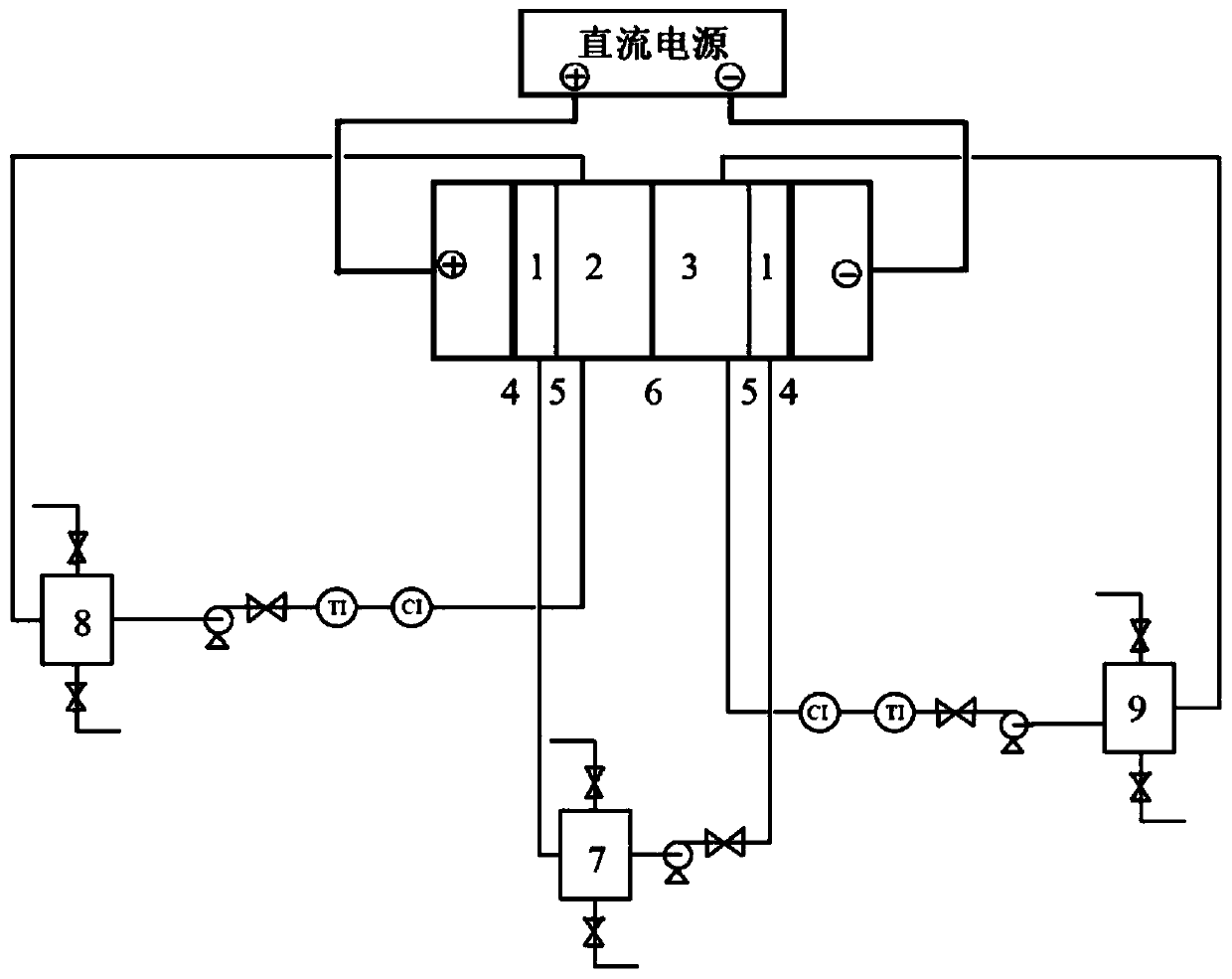

[0034] Step S1, refer to the attached figure 2 , prepared 4% (NH 4 ) 2 SO 4 The solution is placed in the polar water tank (7), 1000 g of pure water is placed in the concentrated water tank (8) of the electrodialysis device, and the eluent obtained above is placed in the fresh water tank (9). Set the operating voltage and current, turn on the power supply, and continue to add dilute acid to keep the pH of the solution at the isoelectric point of L-lysine. Free L-lysine remains in the fresh water chamber in the form of molecules (3), an...

Embodiment 2

[0039] Take 549g of L-lysine hydrochloride and dissolve it in 525g of 20% ammonia water. After fully reacting, add pure water to 3000g to simulate the eluent of ammonia water. At this time, the concentration of free L-lysine is 14.6%. 4 Cl concentration is 5.85%, pH is 10, alloy membrane electrodialysis device (effective membrane area is 1m 2 ) extract the method for L-lysine in the ammonia eluent, comprise the steps:

[0040] Step S1, refer to the attached figure 2 , prepared 4% (NH 4 ) 2 SO 4 The solution is placed in the pole water tank (7), 3000g of pure water is placed in the concentrated water tank (8) of the electrodialysis device, the eluent obtained above is placed in the fresh water tank (9), the operating voltage and current are set, and the power supply is switched on for a continuous The dilute acid keeps the pH of the solution at the isoelectric point of L-lysine, and the free L-lysine remains in the fresh water chamber in the form of molecules (3). The exp...

Embodiment 3

[0045] Get 91.5g of L-lysine hydrochloride and dissolve it in 87.5g of 20% ammonia water. After fully reacting, add pure water to 500g to simulate the ammonia eluent. At this time, the free L-lysine concentration is 14.6%. NH 4 Cl concentration is 5.85%, pH is 9.59, homogeneous membrane electrodialysis device (effective membrane area is 0.055m 2 ) extract the method for L-lysine in the ammonia eluent, comprise the steps:

[0046] Step S1, refer to the attached figure 2 , prepared 4% (NH 4 ) 2 SO 4 The solution is placed in the pole water tank (7), 700g of pure water is placed in the concentrated water tank (8) of the electrodialysis device, the eluent obtained above is placed in the fresh water tank (9), the operating voltage and current are set, and the power is turned on for a continuous Add dilute acid to keep the pH of the solution at the isoelectric point of L-lysine. Free L-lysine remains in the fresh water chamber (3) in the form of molecules. The experiment runs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com