Device and process for preparing methanol and butyl acetate

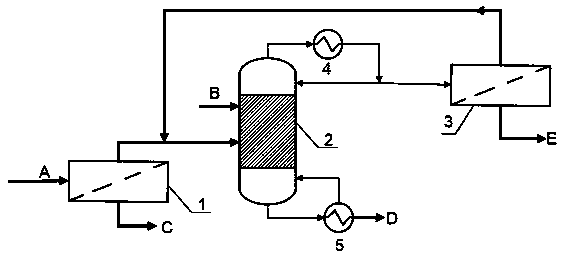

A technology of butyl acetate and methyl acetate, which is applied in the field of reactive distillation-pervaporation integrated methanol and butyl acetate preparation equipment, can solve the problems of high technical energy consumption and complicated equipment, and achieve simple technical route, low equipment investment and low cost. The effect of reduced production cost and easy source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Using the above-mentioned device to prepare methanol and butyl acetate, the working temperature of the membrane module is 40°C, as follows:

[0055] The polyvinyl alcohol (PVA) industry by-produces a large number of methyl acetate-methanol compounds, a typical composition of which is MM20 (70 wt% methanol, 30 wt% methyl acetate). As a typical by-product in the polyvinyl alcohol production industry, methyl acetate-methanol mixture A (70 wt% methanol and 30 wt% methyl acetate) first enters the second pervaporation membrane system 1 for the separation of methyl acetate and methanol. Complete separation, methanol C (99.2mol%) is obtained on the permeate side, and the retentate side is mixed with the return stream and enters the tower from the inlet of methyl acetate, and carries out transesterification reaction with the raw material n-butanol B in the presence of AMBERLYST™ 15 solid acid catalyst, The amount of catalyst used is 10% of the mass of the feed methyl acetate. T...

Embodiment 2

[0057] Using the above-mentioned device to prepare methanol and butyl acetate, the working temperature of the membrane module is 60°C, the details are as follows:

[0058] Polyvinyl alcohol (PVA) industry produces a large number of methyl acetate-methanol compounds, a typical composition of which is MM80 (35 mol% methanol, 65 mol% methyl acetate, approximately azeotropic composition). A typical azeotrope methyl acetate-methanol mixture A (53.5°C, 35 mol% methanol and 65 mol% methyl acetate) in the polyvinyl alcohol production industry first enters the second pervaporation membrane system 1 for methyl acetate and methanol The complete separation of methanol C (99.0mol%) is obtained on the permeate side, and the retentate side is mixed with the return stream and enters the tower from the inlet of methyl acetate, and the raw material n-butanol B is in the ionic liquid [HSO 3 -bHim]HSO 4 The transesterification reaction is carried out in the presence of a catalyst, and the amount...

Embodiment 3

[0060] Using the above device to prepare methanol and butyl acetate, the working temperature of the membrane module is 30°C, the details are as follows:

[0061] Polyvinyl alcohol (PVA) industry produces a large number of methyl acetate-methanol compounds, a typical composition of which is MM80 (35 mol% methanol, 65 mol% methyl acetate, approximately azeotropic composition). A typical azeotrope methyl acetate-methanol mixture A (53.5°C, 35 mol% methanol and 65 mol% methyl acetate) in the polyvinyl alcohol production industry first enters the second pervaporation membrane system 1 for methyl acetate and methanol The complete separation of methanol C (99.0mol%) is obtained on the permeate side, and the retentate side is mixed with the return stream and enters the tower from the inlet of methyl acetate, and carries out transesterification reaction with the raw material n-butanol B in the presence of AMBERLYST™ 15 solid acid catalyst , The amount of catalyst used is 20% of the qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com