Cleaning device for cleaning a transparent cover of an optical or optoelectronic device

A technology for cleaning equipment and photoelectric equipment, which is applied in the direction of optics, optical components, and vehicle cleaning, and can solve problems such as undesired optical distortion of camera images, unfavorable space utilization, weight and cost, and large cleaning fluids, so as to save the need to close And the effect of controlling equipment, saving consumption and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

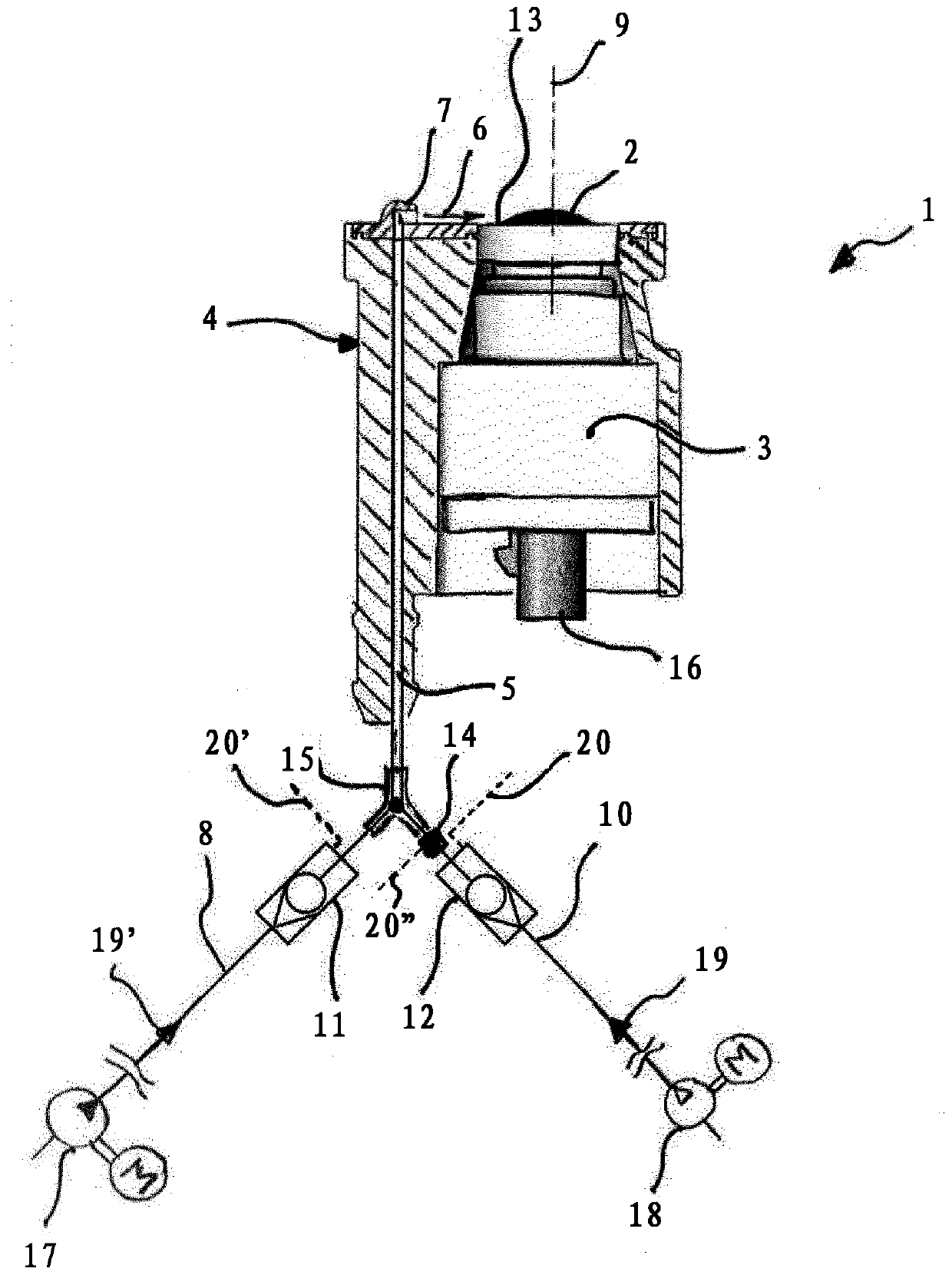

[0025] Arranged in the housing 4 of the cleaning device 1 is an optical device 3 designed as a camera with a transparent element 2 designed as a camera lens. The electrical interface 16 is used to connect the device 3 to one or more power supply means and electronic control units not shown here. The transparent element 2 is curved outwards and has an optical axis 9 .

[0026] Fluid inlet 5 is used to supply cleaning fluid to individual nozzles 7 . Within the present invention, the use of multiple nozzles 7 is allowed at any time.

[0027] The nozzle 7 is designed as a deflector or impingement nozzle. The nozzles form a flat cleaning agent jet 6 which runs transversely to the optical axis 9 in a plane substantially perpendicular to the optical axis. The cleaning agent jet 6 is oriented here in such a way that it hits approximately at the radially outer edge 13 of the transparent element 2 .

[0028] In this case, a property of the fluid called the Coanda effect in hydrodyna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com