Heat-conducting graphene-polymer composite thin film and preparation method and application thereof

A technology of composite film and heat-conducting graphite, which is applied in the field of heat-conducting polymer composite materials, shape-memory polymer composite materials, and functional composite materials. The effects of industrialized manufacturing and low-cost promotion and application, compact process, and easy-to-obtain components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

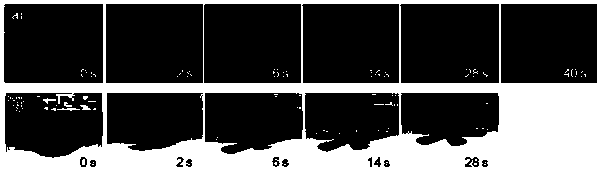

[0031] See attached Figure 1~3 , the heat-driven shape memory heat-conducting graphene-polymer composite film material provided by this embodiment is made of the following components by weight percentage:

[0032] Graphene 10-30,

[0033] Nanocellulose 35-45,

[0034] Polyethylene glycol 35-45.

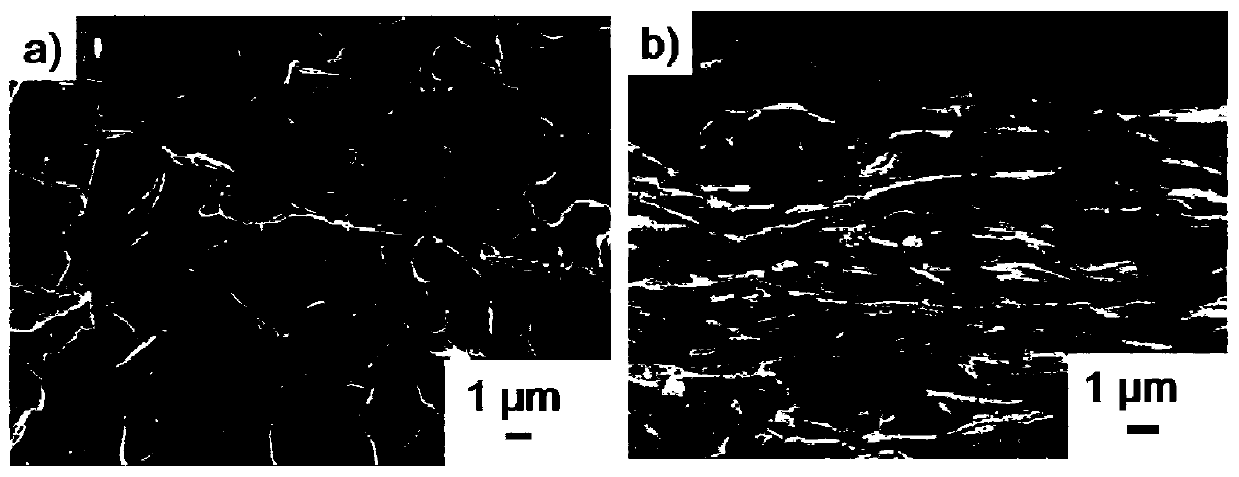

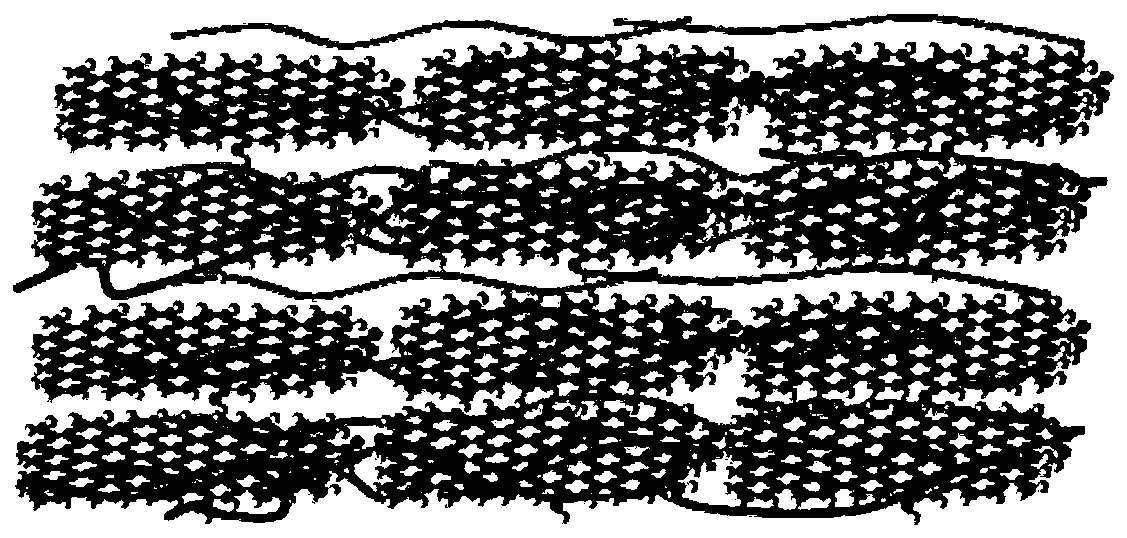

[0035] The average horizontal size of the graphene is 5-10 μm, the average thickness is 6-8 nm, and the oxygen element content is ≤2.50%; the diameter of the nanocellulose is 5-100 nm, and the aspect ratio is 100-1000; polyethylene Diols have a molecular weight of 6,000 to 10,000.

[0036] The preparation method of the heat-conducting graphene-polymer composite film of aforementioned heat-driven shape memory, comprises the following steps:

[0037] (1) Graphene is added into deionized water, ultrasonically dispersed for 0.5-1 h, and a graphene dispersion with a concentration of 1-5 mg / mL is prepared;

[0038] (2) Nanocellulose is added to deionized water, ultrasonically disperse...

Embodiment 2

[0045] The thermally-driven shape memory heat-conducting graphene-polymer composite film material, preparation method and application thereof provided in this embodiment are basically the same as in Example 1, except that:

[0046] The weight percentage of graphene, nanocellulose and polyethylene glycol for preparing the composite film material is 20:40:40.

[0047] The preparation method of the thermally-driven shape memory heat-conducting graphene-polymer composite film comprises the following steps:

[0048] (1) Graphene is added into deionized water, ultrasonically dispersed for 0.5h, and a graphene dispersion with a concentration of 5mg / mL is prepared;

[0049] (2) adding nanocellulose into deionized water, ultrasonically dispersing for 0.5 h, and preparing a nanocellulose dispersion with a concentration of 5 mg / mL;

[0050] (3) Polyethylene glycol was added to deionized water, ultrasonically dispersed for 0.5 h, and a polyethylene glycol dispersion with a concentration of...

Embodiment 3

[0055] The steps of this embodiment are the same as those of Example 1, the difference being the weight ratio of graphene, nanocellulose and polyethylene glycol in the thermally conductive graphene-polymer composite film of heat-driven shape memory described in this embodiment For 25:37.5:37.5.

[0056] The thermal conductivity of the thermally actuated shape memory thermally conductive graphene-polymer composite film prepared in Example 3 was tested with a laser thermal conductivity meter LFA447 from the German Netzsch Company, and the test result was: the transverse thermal conductivity was 12.46W m -1 ·K -1 , and has very good flexibility, after bending 500 degrees, the thermal conductivity ranges from 0 to 10%. The shape recovery rate of the composite film within 60s at 70°C is greater than 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com