Electrocatalytic oxidation filler, preparation method thereof and three-dimensional electrocatalytic oxidation device

A technology of electrocatalytic oxidation and metal catalyst, applied in chemical instruments and methods, water treatment parameter control, water/sewage treatment equipment, etc., can solve problems such as low current efficiency, long mass transfer distance, and no mature and effective industrialized treatment methods , to achieve the effects of low energy consumption, improved catalytic activity and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An electrocatalytic oxidation catalytic filler is prepared by roasting after mixing a catalyst carrier and a metal catalyst solution, wherein the catalyst carrier is a mixture of clay minerals and a curing agent, and the metal catalyst solution is Cu 2+ / Mn 2+ mixed solution.

[0031] In this embodiment, the clay mineral is a mixture of clay, diatomaceous earth and bentonite, wherein the mass ratio of clay, diatomaceous earth and bentonite is 5:2:3.

[0032] In this embodiment, the curing agent is a silica gel solution with a mass concentration of 30% (the solvent is water); the mass of the curing agent is 0.05% of the clay mineral mass.

[0033] In this example, Cu 2+ / Mn 2+ The mixed solution is a mixed solution of copper acetate and manganese acetate, wherein Cu in the mixed solution of copper acetate and manganese acetate 2+ , Mn 2+ The molar ratio is 1:1, and the mass percentage of copper acetate and manganese acetate in the mixed solution of copper acetate and ...

Embodiment 2

[0039] A three-dimensional electrocatalytic oxidation device, comprising an anode and a cathode, wherein the electrocatalytic oxidation filler prepared in Example 1 is filled between the anode and the cathode.

[0040] In this embodiment, the three-dimensional electrocatalytic oxidation device has a cylindrical structure, and the center is IrO 2 -RuO 2 The / Ti rod is used as the anode, and the surrounding stainless steel plate is used as the cathode.

[0041] In this example, IrO 2 -RuO 2 The diameter of the / Ti rod is 100mm; the diameter of the cathode is 400mm, and the effective height of the anode and cathode is 6000mm.

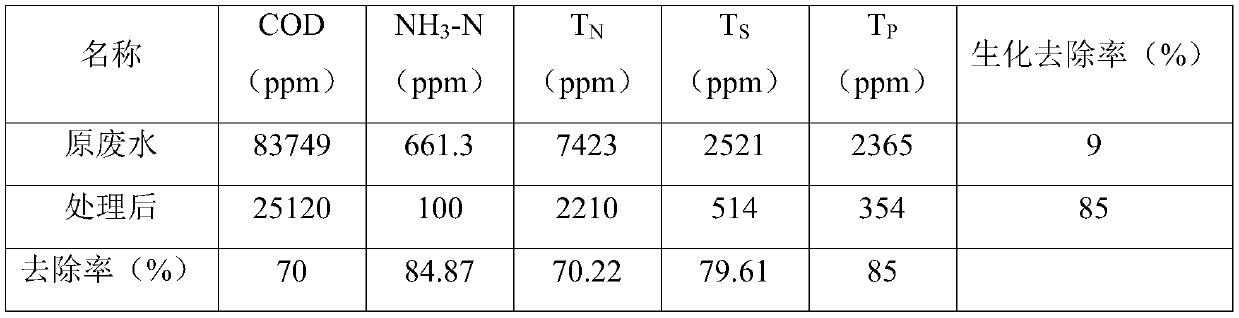

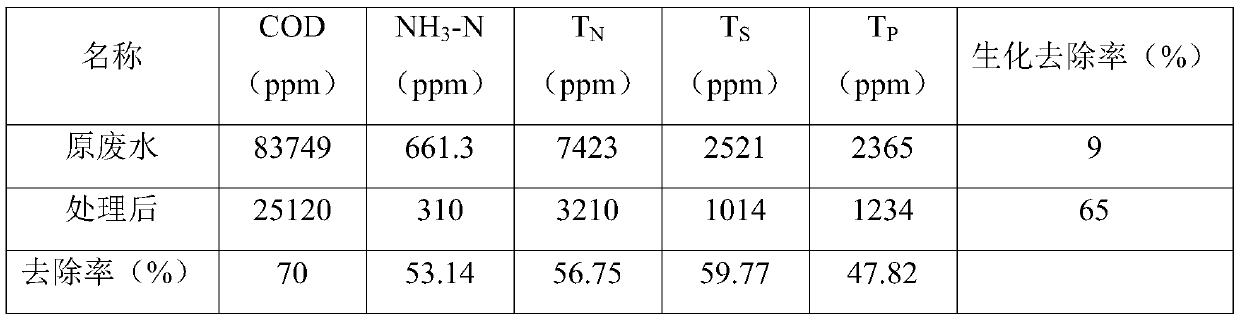

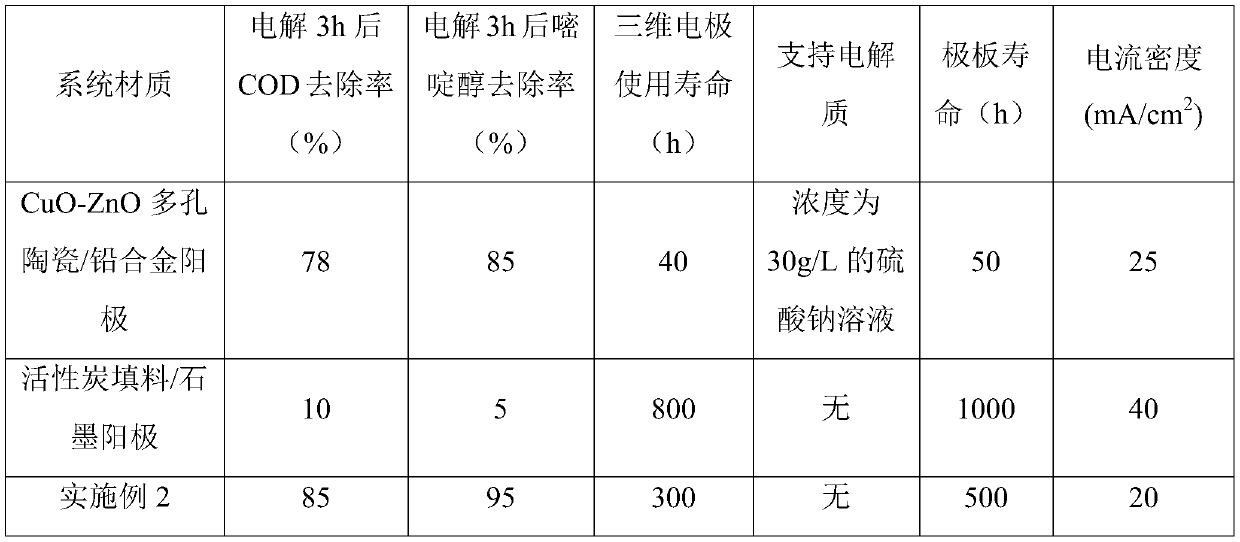

[0042] The three-dimensional electrocatalytic oxidation device in Example 2 is organically combined with the stripping tower to form a three-dimensional electrocatalytic oxidation stripping tower, and the treatment effect of the three-dimensional electrocatalytic oxidation stripping tower on pyrimiphos-methyl wastewater is investigated at the same time,...

Embodiment 3

[0061] An electrocatalytic oxidation catalytic filler is prepared by roasting after mixing a catalyst carrier and a metal catalyst solution, wherein the catalyst carrier is a mixture of clay minerals and a curing agent, and the metal catalyst solution is Cu 2+ / Mn 2+ mixed solution.

[0062] In this embodiment, the clay mineral is a mixture of clay, diatomite and bentonite, wherein the mass ratio of clay, diatomite and bentonite is 6:3:1.

[0063] In this embodiment, the curing agent is water glass with a mass concentration of 30%; the quality of the curing agent is 0.05% of the clay mineral weight.

[0064] In this example, Cu 2+ / Mn 2+ The mixed solution is a mixed solution of copper acetate and manganese acetate, wherein Cu in the mixed solution of copper acetate and manganese acetate 2+ , Mn 2+ The molar ratio is 1:2, and the mass percent content of copper acetate and manganese acetate in the mixed solution of copper acetate and manganese acetate is 10%; the mass perc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com