Glass punching device facilitating positioning and processing

A punching device and glass technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of wasting resources, glass parts punching and breaking, affecting production efficiency, etc., to achieve a clean and tidy working environment, drilling The hole is stable, reliable and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

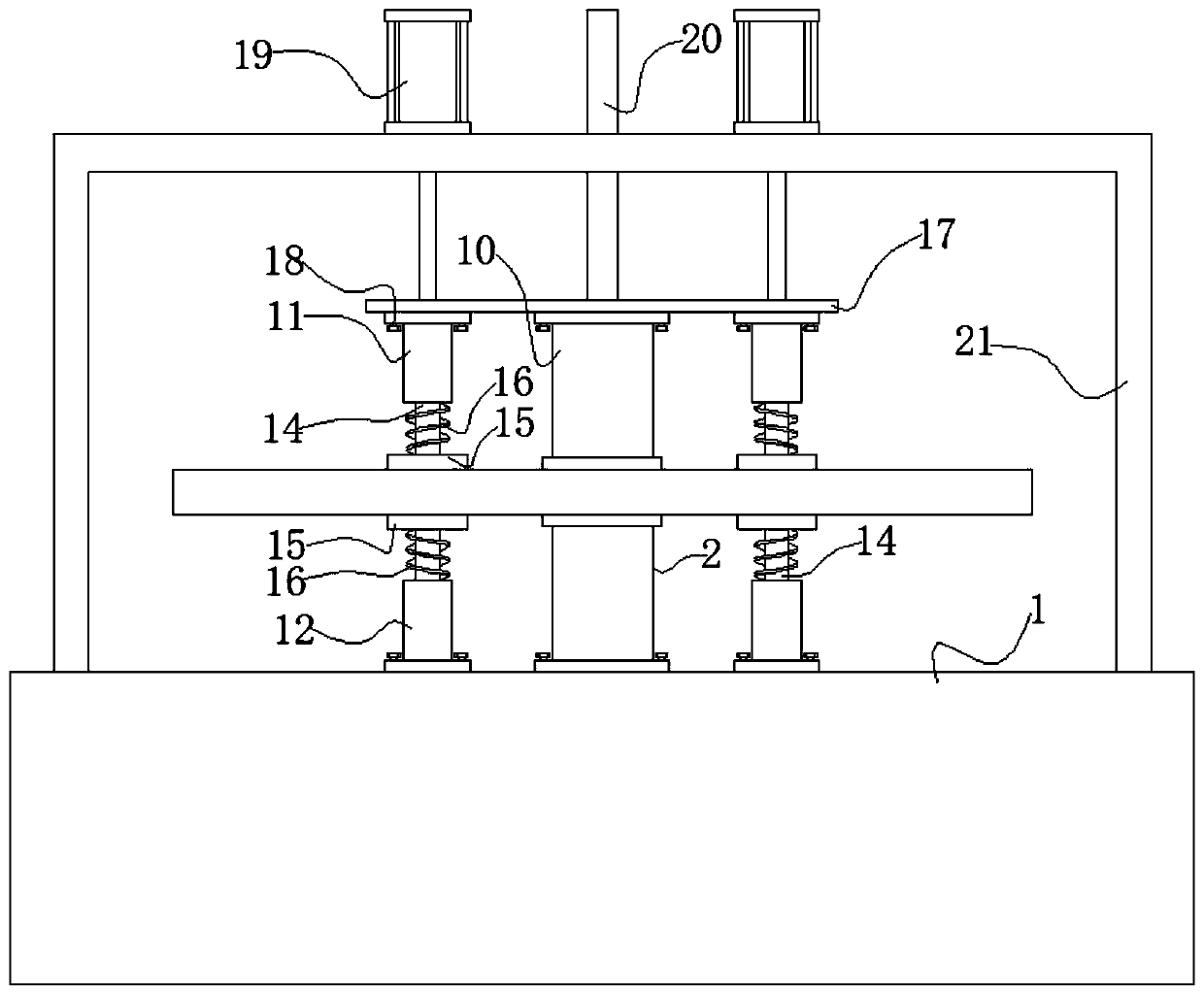

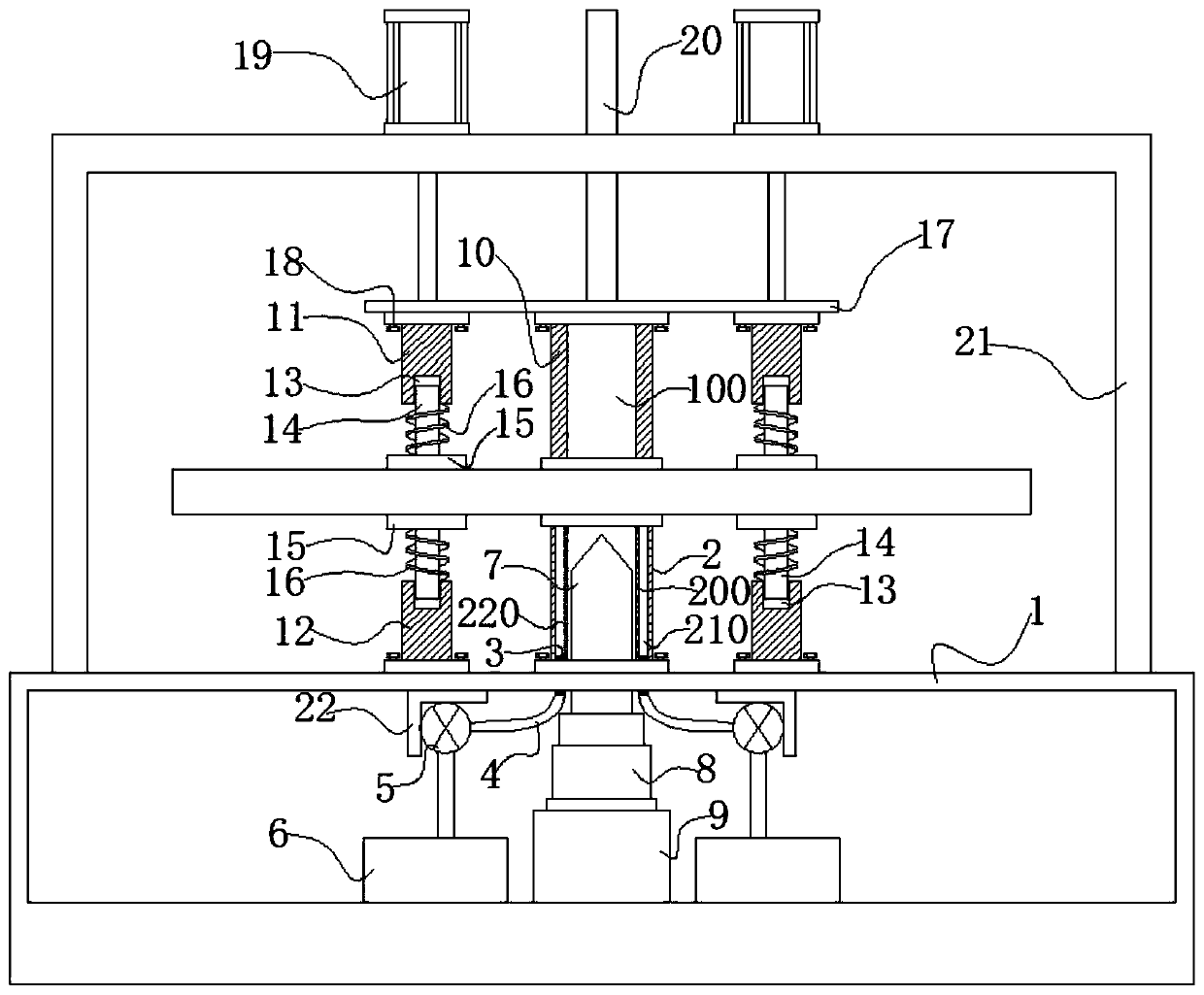

[0019] Such as Figure 1-2 As shown, the specific embodiment of the present invention is: a glass punching device that is convenient for positioning and processing, including a base box 1 and a lower positioning seat 2. The lower positioning seat 2 is fixedly installed at the middle position of the base box 1, so that The inner cavity of the lower positioning seat 2 is provided with an inner casing 200 of an integral structure, and several evenly distributed slag through holes 220 are provided on the inner casing 200. The inner casing 200 and the lower positioning seat 2 A gap cavity is formed between the outer walls of the outer walls, and the formed gap cavity is a slag material absorption cavity 210, and the bottom of both sides of the slag material absorption cavity 210 is inserted with a hard short tube 3, and the hard short tube 3 The bottom end extends downwards into the interior of the base box 1, and the bottom end of the hard short pipe 3 that extends downwards is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com