A barrier layer, sintering mold and preparation method thereof

A barrier layer and mold technology, which is applied in the field of building decoration materials, can solve the problems of low mold/shelf board fit, easy breakage, pulverization, and work environment pollution, so as to prevent environmental pollution and affect health, reduce damage, Eliminate the effect of fitting the dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

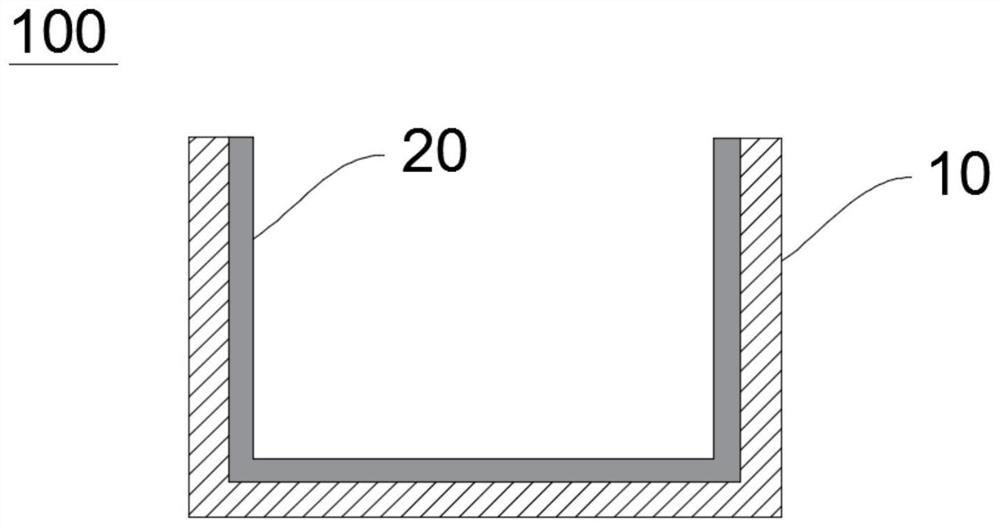

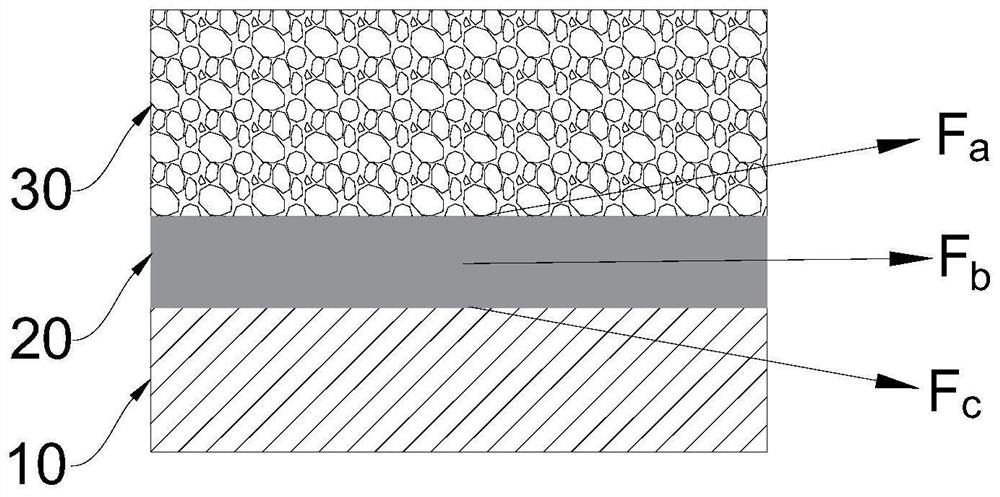

[0084] An embodiment of the present invention also provides a method for preparing a sintered mold, comprising the following steps:

[0085] Weigh the solid powder raw materials of quartz sand, zirconia, alumina, carbide and nitride, then add solvent, stir evenly to obtain a mixed slurry; the carbide includes one of silicon carbide, tungsten carbide and boron carbide or more, the nitride includes one or more of silicon nitride, boron nitride and tungsten nitride;

[0086] A sintered mold body is provided, the mixed slurry is evenly coated on the surface of the sintered mold body, and after drying, a barrier layer is formed on the surface of the sintered mold body to obtain a finished sintered mold.

[0087] Optionally, the sintering mold body includes one or more of high temperature resistant kiln furniture, high temperature resistant mold and shelving. The high-temperature-resistant kiln furniture or high-temperature-resistant mold can be traditional existing kiln furniture ...

Embodiment 1

[0126] A method for preparing a sintered mould, comprising:

[0127] Weigh 10g of quartz sand, 2g of zirconia, 2.5g of alumina, 2g of tungsten carbide and 2g of boron nitride as solid powder raw materials, then add 30mL of 50% ethanol solution, and stir to obtain a mixed slurry;

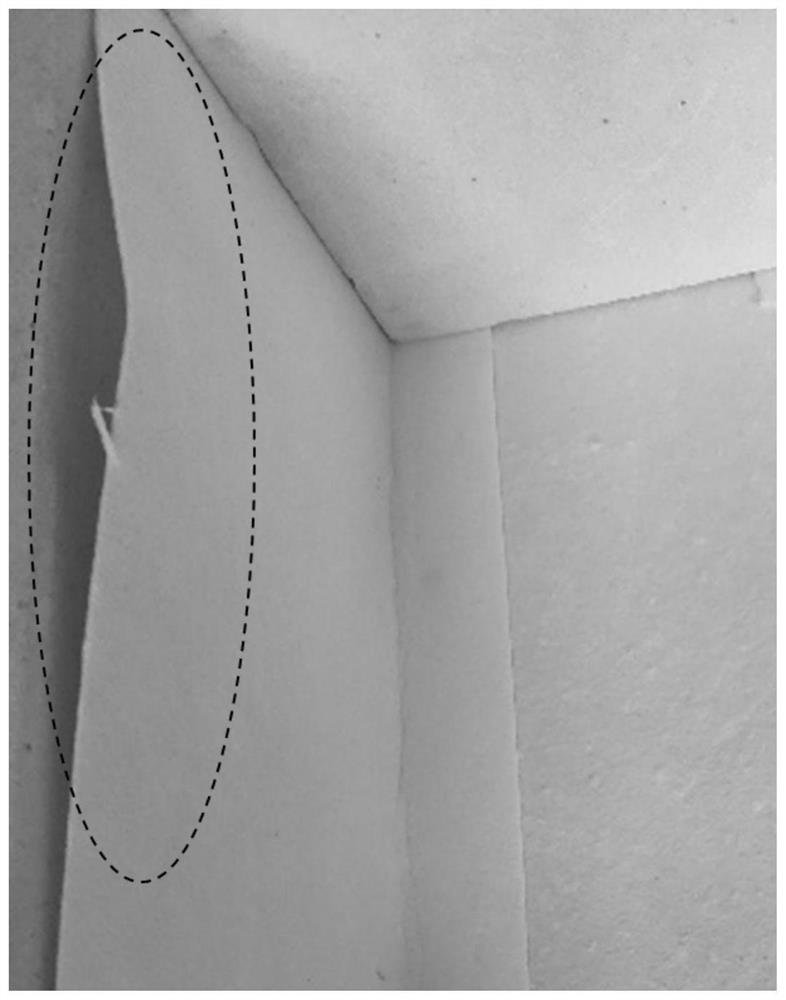

[0128] Provide a mold and shed plate enclosed by four side plates and a bottom plate, apply the mixed slurry evenly on the inner surface of the mold and the surface of the shed plate, and dry at 100°C for 2 hours to obtain a barrier on the surface Layers of sintering molds and shelving boards.

Embodiment 2

[0130] A method for preparing a sintered mould, comprising:

[0131] Weigh 15g of quartz sand, 2g of zirconia, 10g of alumina, 2g of tungsten carbide and 2g of boron nitride as solid powder raw materials, then add 40mL of 50% ethanol solution, and stir to obtain a mixed slurry;

[0132] Provide a mold and shed plate enclosed by four side plates and a bottom plate, evenly coat the mixed slurry on the inner surface of the mold and the surface of the shed plate, and then sinter at 1600-1700°C for 10 hours to obtain a surface A sintering mold and a shelving plate with a barrier layer are formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com