Barrier layer, sintering mold and preparation method thereof

A barrier layer and mold technology, applied in the field of building decoration materials, can solve problems such as difficult laying, easy tearing, and work environment pollution, and achieve the effects of easy demoulding, good high temperature resistance, and reduced environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

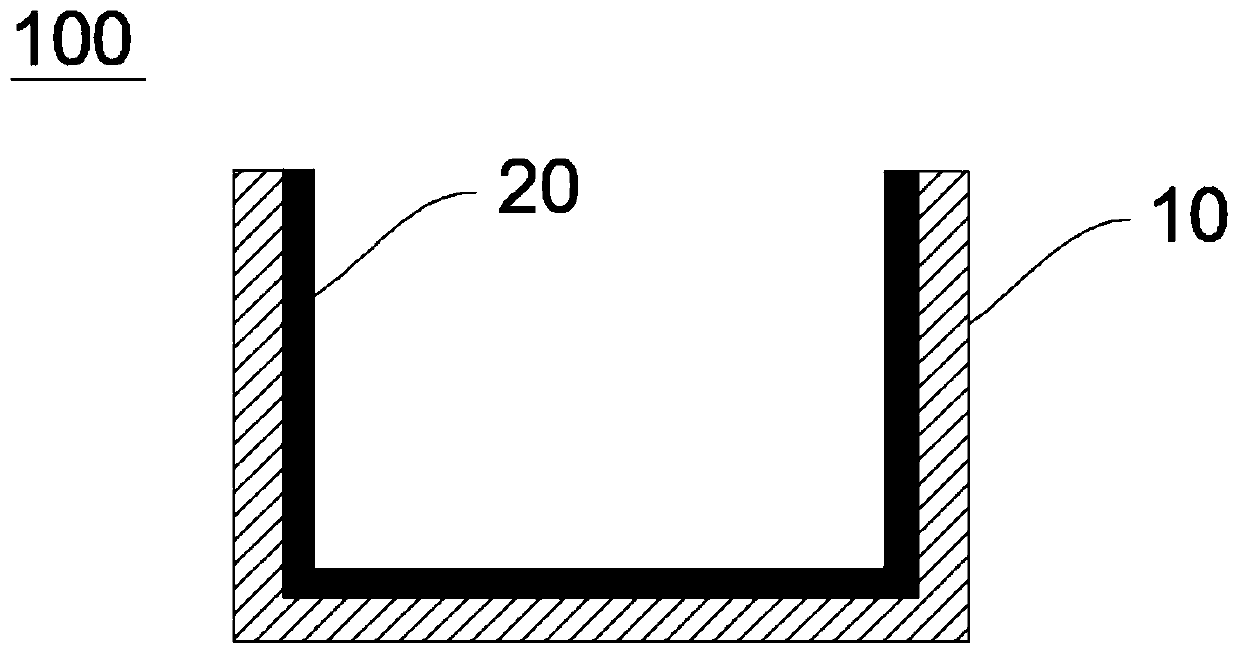

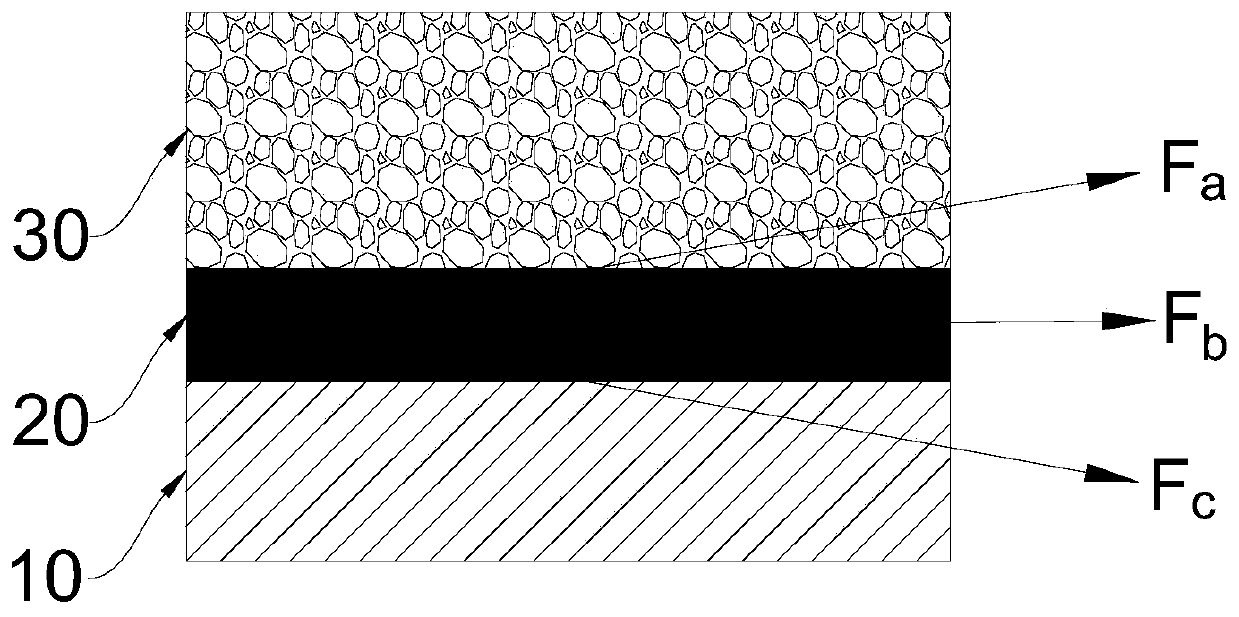

[0084] An embodiment of the present invention also provides a method for preparing a sintered mold, comprising the following steps:

[0085] Weigh the solid powder raw materials of quartz sand, zirconia, alumina, carbide and nitride, then add solvent, stir evenly to obtain a mixed slurry; the carbide includes one of silicon carbide, tungsten carbide and boron carbide or more, the nitride includes one or more of silicon nitride, boron nitride and tungsten nitride;

[0086] A sintered mold body is provided, the mixed slurry is evenly coated on the surface of the sintered mold body, and after drying, a barrier layer is formed on the surface of the sintered mold body to obtain a finished sintered mold.

[0087] Optionally, the sintering mold body includes one or more of high temperature resistant kiln furniture, high temperature resistant mold and shelving. The high-temperature-resistant kiln furniture or high-temperature-resistant mold can be traditional existing kiln furniture ...

Embodiment 1

[0126] A method for preparing a sintered mould, comprising:

[0127] Weigh 10g of quartz sand, 2g of zirconia, 2.5g of alumina, 2g of tungsten carbide and 2g of boron nitride as solid powder raw materials, then add 30mL of 50% ethanol solution, and stir to obtain a mixed slurry;

[0128] Provide a mold and shed plate enclosed by four side plates and a bottom plate, apply the mixed slurry evenly on the inner surface of the mold and the surface of the shed plate, and dry at 100°C for 2 hours to obtain a barrier on the surface Layers of sintering molds and shelving boards.

Embodiment 2

[0130] A method for preparing a sintered mould, comprising:

[0131] Weigh 15g of quartz sand, 2g of zirconia, 10g of alumina, 2g of tungsten carbide and 2g of boron nitride as solid powder raw materials, then add 40mL of 50% ethanol solution, and stir to obtain a mixed slurry;

[0132] Provide a mold and shed plate enclosed by four side plates and a bottom plate, evenly coat the mixed slurry on the inner surface of the mold and the surface of the shed plate, and then sinter at 1600-1700°C for 10 hours to obtain a surface A sintering mold and a shelving plate with a barrier layer are formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com