Double-drive structure of roller cam single-output shaft

A technology of roller cam and output shaft, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc. It can solve the problems of affecting the indexing precision of the rotary table, difficult space configuration, and enlarging the volume of the servo motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

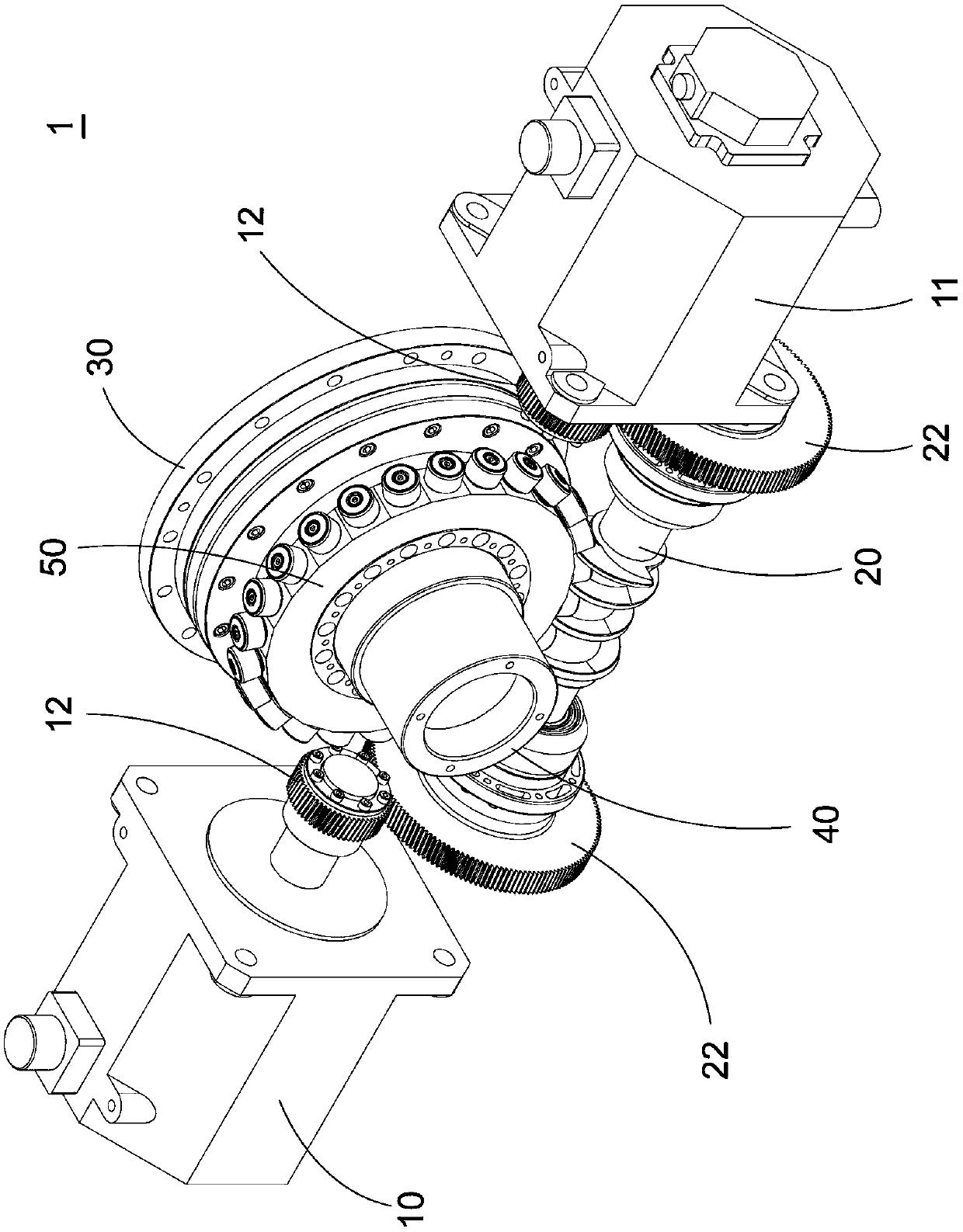

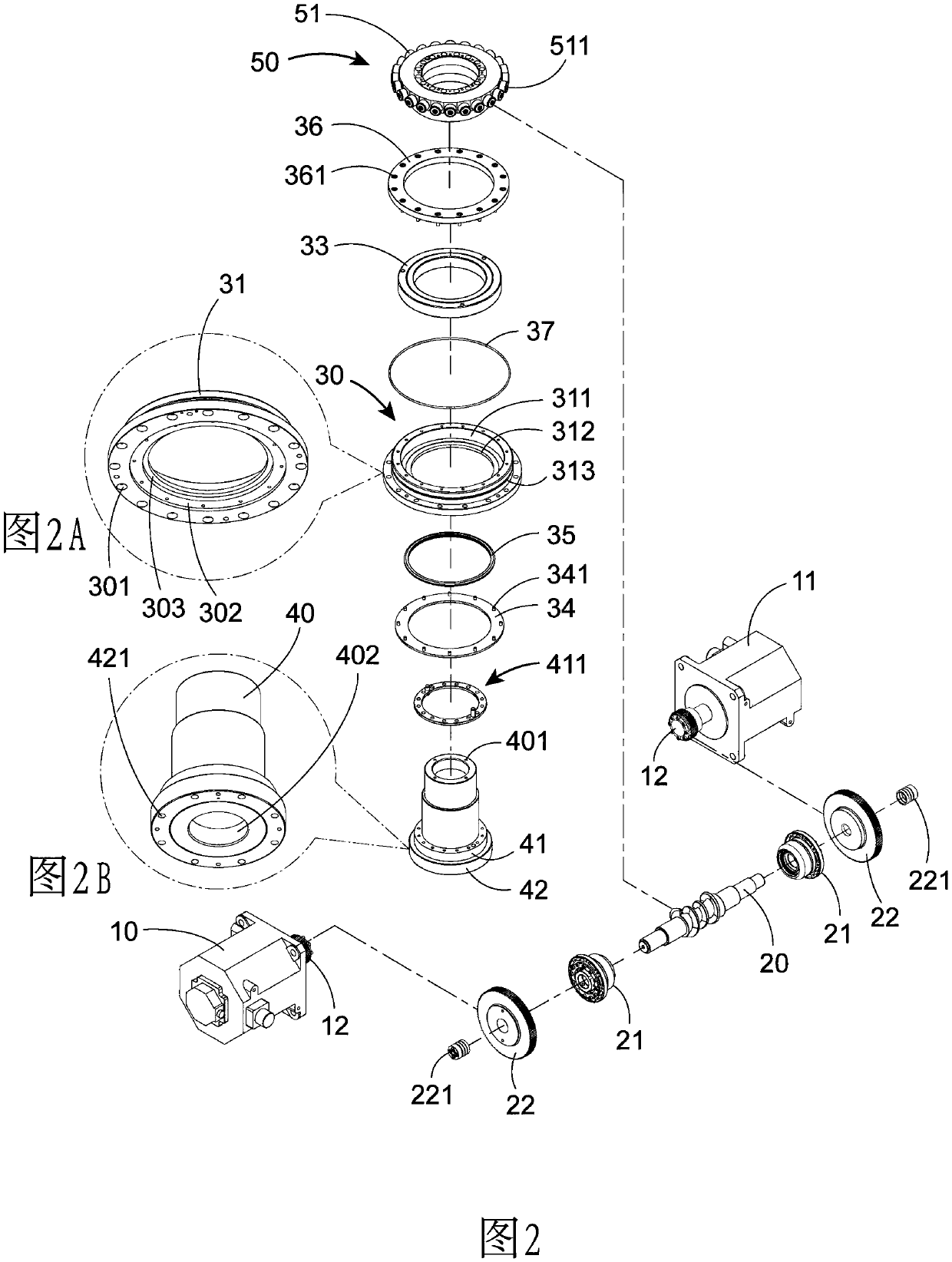

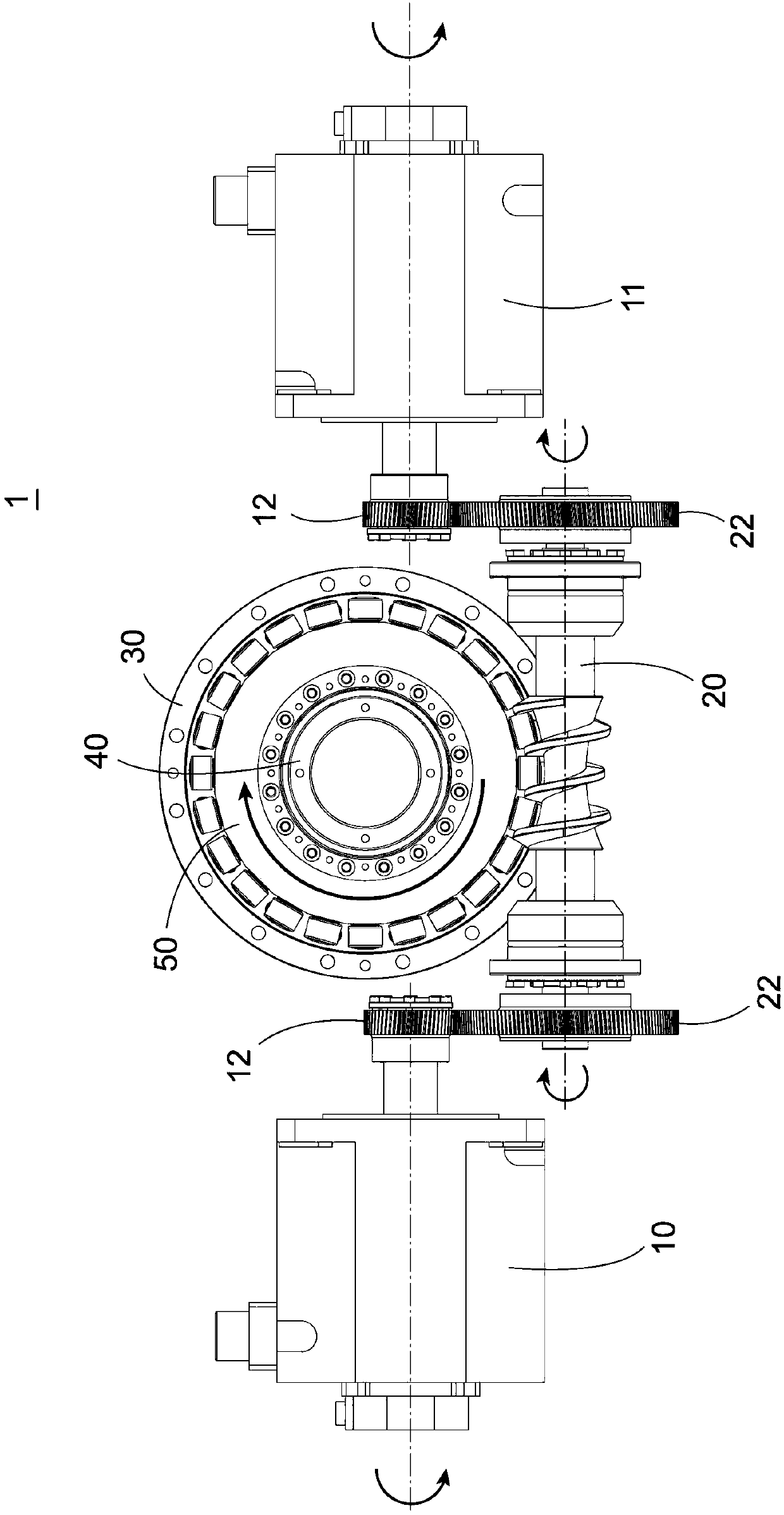

[0029] see Figure 1 to Figure 4 As shown, the preferred embodiment of the dual drive structure of the roller cam single output shaft of the present invention, but these embodiments are for illustration purposes only, and are not limited by this structure in patent applications, which include:

[0030] see Figure 1 to Figure 2 As shown, a double drive structure 1 with a roller cam and a single output shaft is used to give a driving force to a turning-milling composite swing head or a rotary table (index plate) of a horizontal processing machine, which includes A main power base 10 and at least one auxiliary power base 11, the output axis of the auxiliary power base 11 is parallel to the output axis of the main power base 10, the main power base 10 and the auxiliary power base 11 are respectively connected with a power wheel 12, The main power base 10 and the auxiliary power base 11 are driving motors, and the driving motors are controlled by a computer numerical control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com