Sodium combustion experimental device and method for obtaining sodium aerosol with extreme low concentration

An experimental device, sodium gas technology, applied in the field of reactors, can solve the problems of uncontrollable reaction, difficult operation, and extremely violent reaction of sodium water, etc., to avoid the generation of large-concentration aerosol, simple operation process, and small action area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to illustrate the technical solution of the present disclosure more clearly, the following describes in detail in conjunction with specific implementation methods:

[0029] The sodium combustion experimental device of the present disclosure is characterized in that the device comprises: a sodium combustion reactor 3 and an igniter 5; wherein the igniter 5 is for the sodium combustion reactor 3 to ignite;

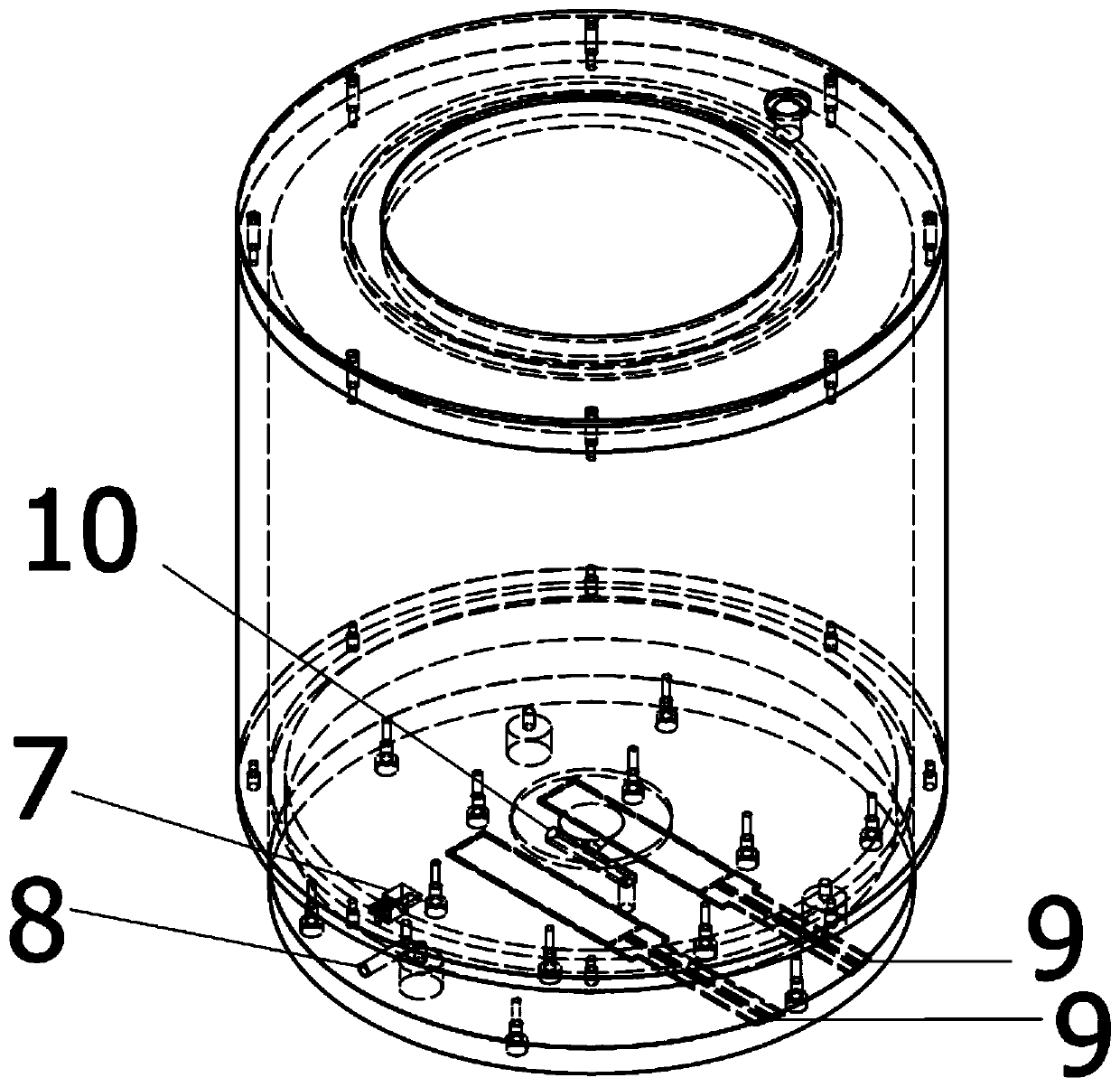

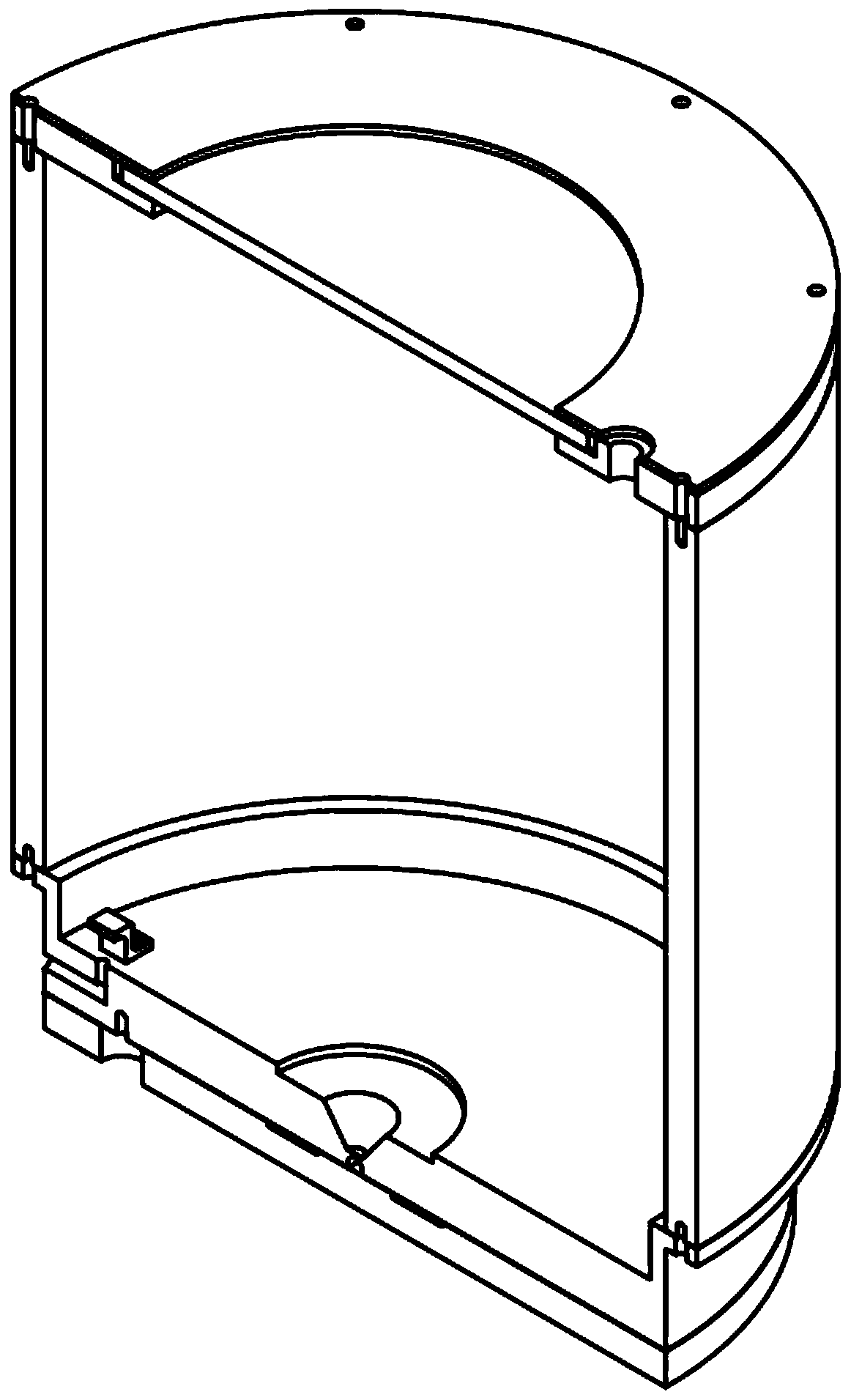

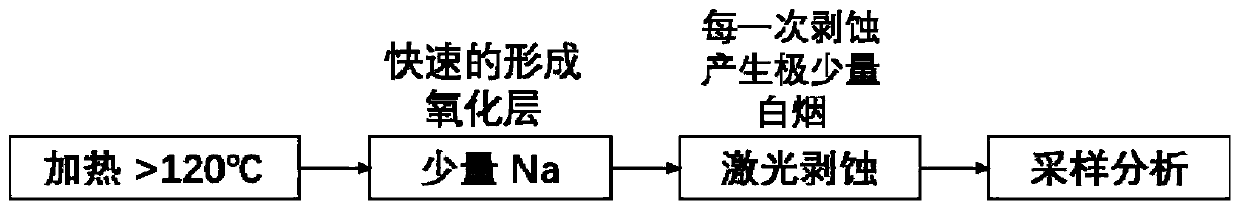

[0030] The sodium combustion reactor 3 is designed as a cylindrical structure, made of stainless steel, and has a conical groove and a cylindrical groove at the bottom as a sodium pool. The sodium pool is heated by a ceramic electric heater, which can preheat the metal sodium 6 placed therein and melt it into a liquid state. The heating temperature is controlled and monitored by the thermocouple 10 and the temperature control circuit installed under the sodium pool. The top of the cylinder is a quartz window, which can be used for combustion state observation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com