Sculpture cement and preparation method thereof

A cement and sculpture technology, applied in the field of sculpture cement and its preparation, can solve the problems such as stability, strength and toughness need to be further improved, anti-cracking and plasticity are poor, and achieve better construction performance and stability, anti-cracking and other problems. And the effect of good plasticity and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of described D-gluconic acid 2-propene-1-ester / allyl succinimidyl carbonate / acrylic acid ester / terpineol propionate copolymer comprises the steps of: making D-glucose Add 2-propene-1-sugaric acid, allyl succinimidyl carbonate, acrylate, terpineol propionate, and an initiator into a high-boiling solvent, and stir and react for 3-5 hours under a nitrogen atmosphere. Rear rotary evaporation removes solvent, obtains D-gluconic acid 2-propylene-1-ester / allyl succinimidyl carbonate / acrylic acid ester / terpinyl propionate copolymer; Said D-gluconate The mass ratio of acid 2-propen-1-ester, allyl succinimidyl carbonate, acrylate, terpineol propionate, initiator, and high boiling point solvent is 1:1:2:1:(0.04- 0.06): (15-20); The initiator is at least one of azobisisobutyronitrile and azobisisoheptanonitrile; the high boiling point solvent is N, N-dimethylformamide, N , at least one of N-dimethylacetamide and N-methylpyrrolidone.

[0024] Further, the ad...

Embodiment 1

[0029] Embodiment 1 provides a kind of sculpture cement, it is characterized in that, comprises the following components by weight: 40 parts of ordinary Portland cement, 20 parts of gypsum, 40 parts of borax, 5 parts of basalt powder, 8 parts of glue, shell 0.05 part of polysaccharide fiber, 0.3 part of additive; the particle diameter of the borax is 100 mesh; the particle diameter of the basalt powder is 120 mesh.

[0030]The glue is made from the following raw materials in parts by weight: 20 parts of hyperbranched polyglycidyl ether, 10 parts of carrageenan, 3 parts of glycerol monopalmitate, 2-propene-1-ester of D-gluconate / Allyl succinimidyl carbonate / acrylate / terpineol propionate copolymer 5 parts.

[0031] The preparation method of described D-gluconic acid 2-propene-1-ester / allyl succinimidyl carbonate / acrylic acid ester / terpineol propionate copolymer comprises the steps of: making D-glucose Add 100g of 2-propen-1-sugaric acid, 100g of allyl succinimidyl carbonat...

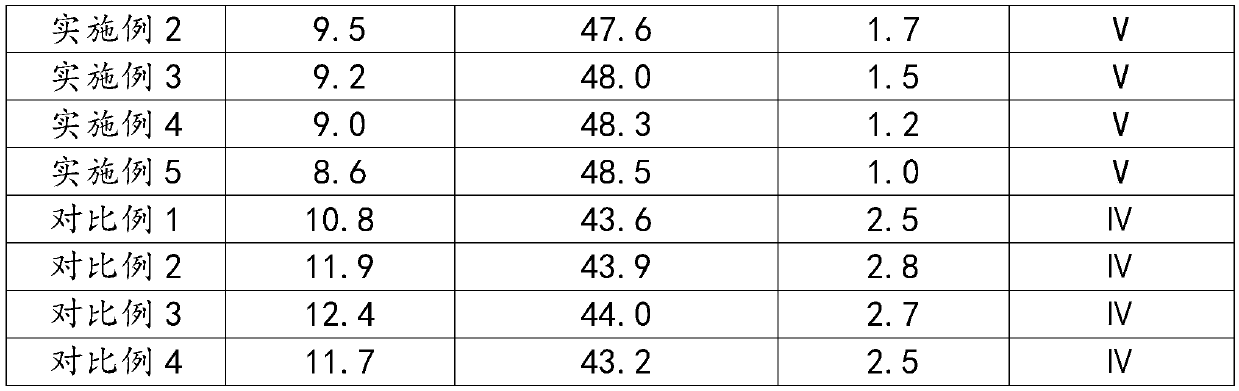

Embodiment 2

[0035] Embodiment 2 provides a kind of sculpture cement, its formulation and preparation method are basically the same as in Example 1, the difference is that the sculpture cement is made of the following components by weight: 43 parts of ordinary portland cement, gypsum 22 parts, 42 parts of borax, 6 parts of basalt powder, 9 parts of glue, 0.2 part of chitosan fiber, 0.4 part of additive; The glue is made of the following raw materials in parts by weight: 23 parts of hyperbranched polyglycidyl ether , 12 parts of carrageenan, 3.5 parts of glycerol monopalmitate, 6 parts of 2-propene-1-D-gluconate / allyl succinimidyl carbonate / acrylate / terpineol propionate copolymer .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com