A method for preparing fto conductive glass by near space sublimation technology

A near-space sublimation, conductive glass technology, applied in coatings and other directions, can solve the problems of insufficient large-scale production development, easy shrinkage and cracking, large film thickness, etc., to improve the photon utilization rate or photoelectric conversion rate, and comprehensive photoelectric performance. The effect of optimization, heat radiation performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The present invention is not limited to this embodiment, and other embodiments may belong to the scope of the present invention as long as it conforms to the gist of the present invention.

[0047] In a preferred embodiment of the present invention, based on the above problems existing in the prior art, a method for preparing FTO conductive glass by using a near-space sublimation technology is provided, such as figure 1 shown, including:

[0048] Step S1, mixing CH3OH, HO(CH2)2NH2 and NH3·H2O according to a first ratio to obtain a first solution;

[0049] Step S2, adding SnCl to the first solution and stirring continuously to obtain a second solution;

[0050] SnCl4·5H2O and HO(CH2)2NH2 have a second ratio;

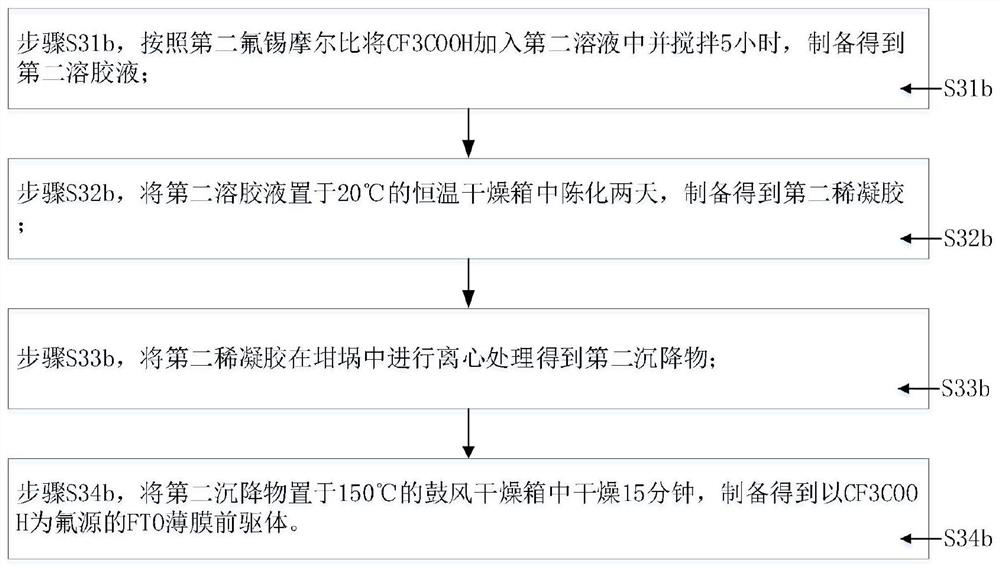

[0051] Step S3, doping the second solution with a fluorine source to prepare an FTO thin film precursor;

[0052] In step S4, near-spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com