Monitoring method of tool state in deep hole inner thread machining

A technology for internal thread processing and cutting tools, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor processing accuracy and low pass rate, and achieve the effect of improving processing accuracy and ensuring processing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to illustrate the present invention more specifically, the present invention is illustrated by the following specific embodiments:

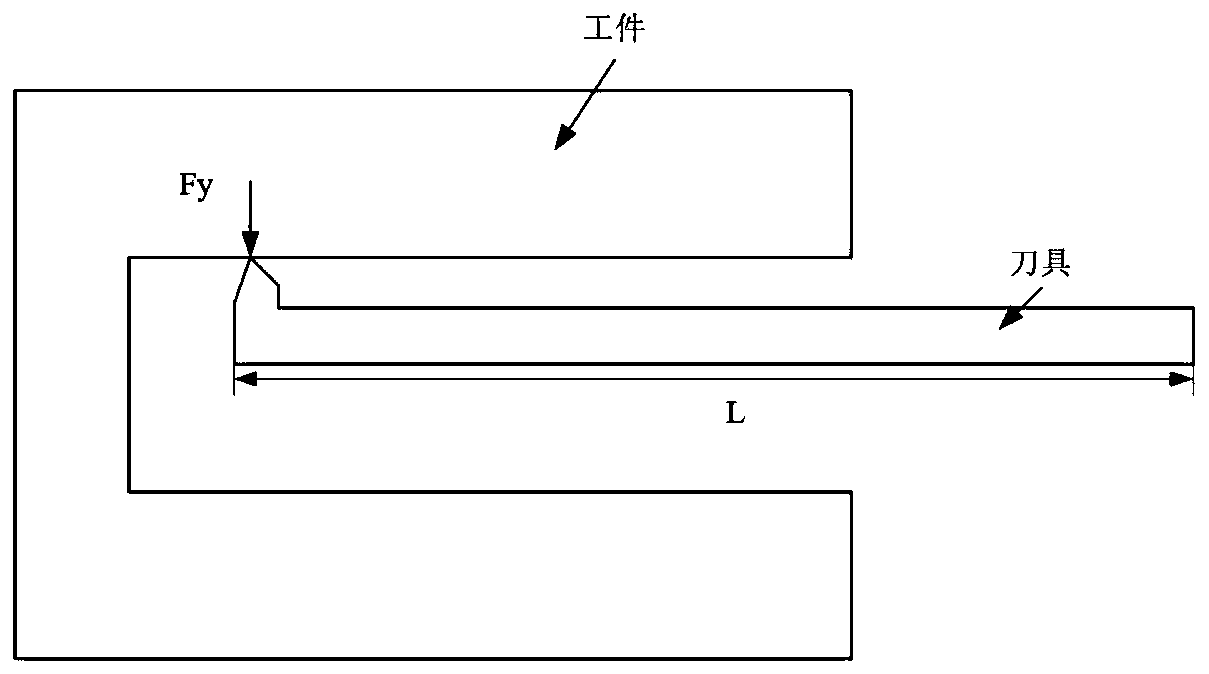

[0026] The machining process of deep hole variable groove width thread is as figure 1 Shown.

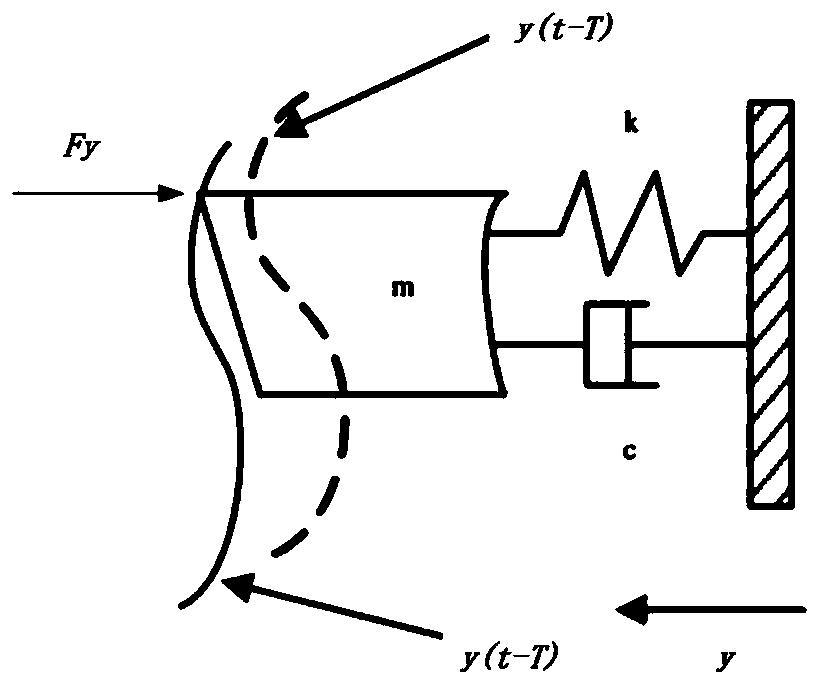

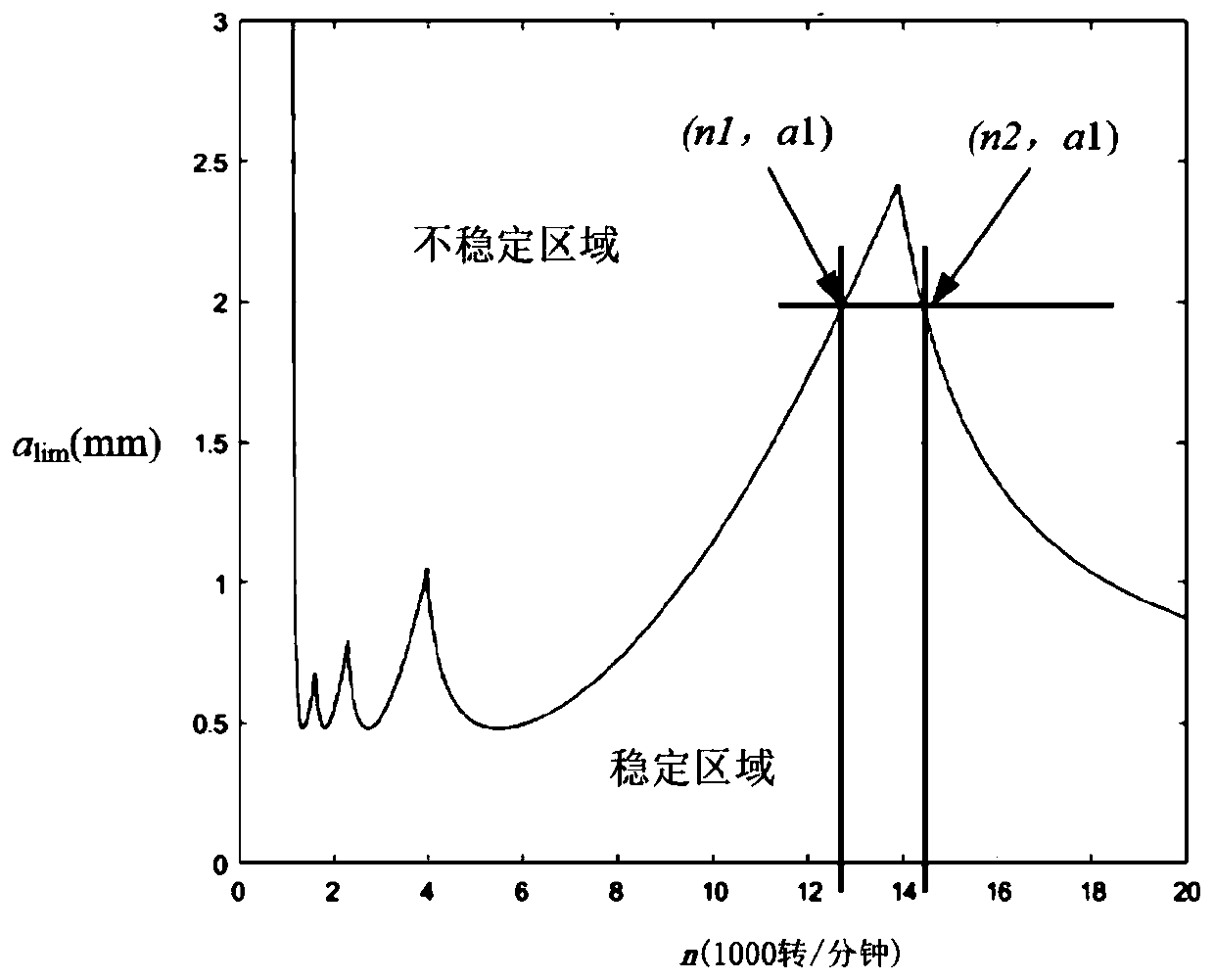

[0027] Considering the actual working conditions of variable groove width thread processing, the two ends of the workpiece are clamped, and the tool cantilever penetrates deep into the workpiece to process the thread. The rigidity of the workpiece is usually large, and the impact on processing can be ignored. The tool cantilever extends into the workpiece to process the thread. , The rigidity is relatively low, which has a greater impact on processing. Therefore, considering the cantilever extension stiffness of the tool can meet the usual requirements. The dynamic model of the machining process is such as figure 2 Shown.

[0028] The dynamic equation is as follows

[0029]

[0030]

[0031] Where m is the modal mass of the toolholder, c is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com