Crown-shaped oxygen-deficient tin oxide nanosheet array structure and preparation method thereof

A nanosheet array and nanostructure technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, inorganic chemistry, etc., can solve the problems of low photocatalytic activity and low utilization rate of solar energy, etc. Increased specific surface area, controllable morphology, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the crown anoxic tin oxide nanosheet array structure proposed by the present invention includes the following steps and contents:

[0036] (1) First, put 20-60mL of deionized water in a beaker, then dissolve 2.0-4.2g of stannous chloride dihydrate and 2.6-6.0g of trisodium citrate in it, and magnetically stir for 20-40min to obtain uniform, Stable white thick suspension, and then slowly add absolute ethanol into the beaker according to the volume ratio of absolute ethanol: deionized water 1:1-1:4, and continue to stir for 30-60min to obtain a milky white turbid liquid precursor ,spare.

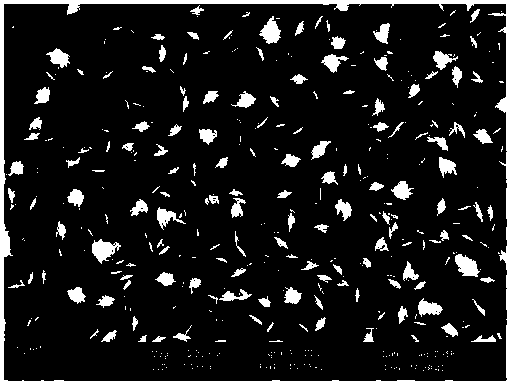

[0037] (2) Transfer the precursor solution to the high-pressure stainless steel reactor, and fix the clean nickel foam sheet horizontally on the bottom of the reactor. Then, after the sealing and assembly of the reaction kettle is completed, it is placed in an oven for heat preservation treatment. After naturally cooling to room temperature, the reactor was o...

Embodiment 1

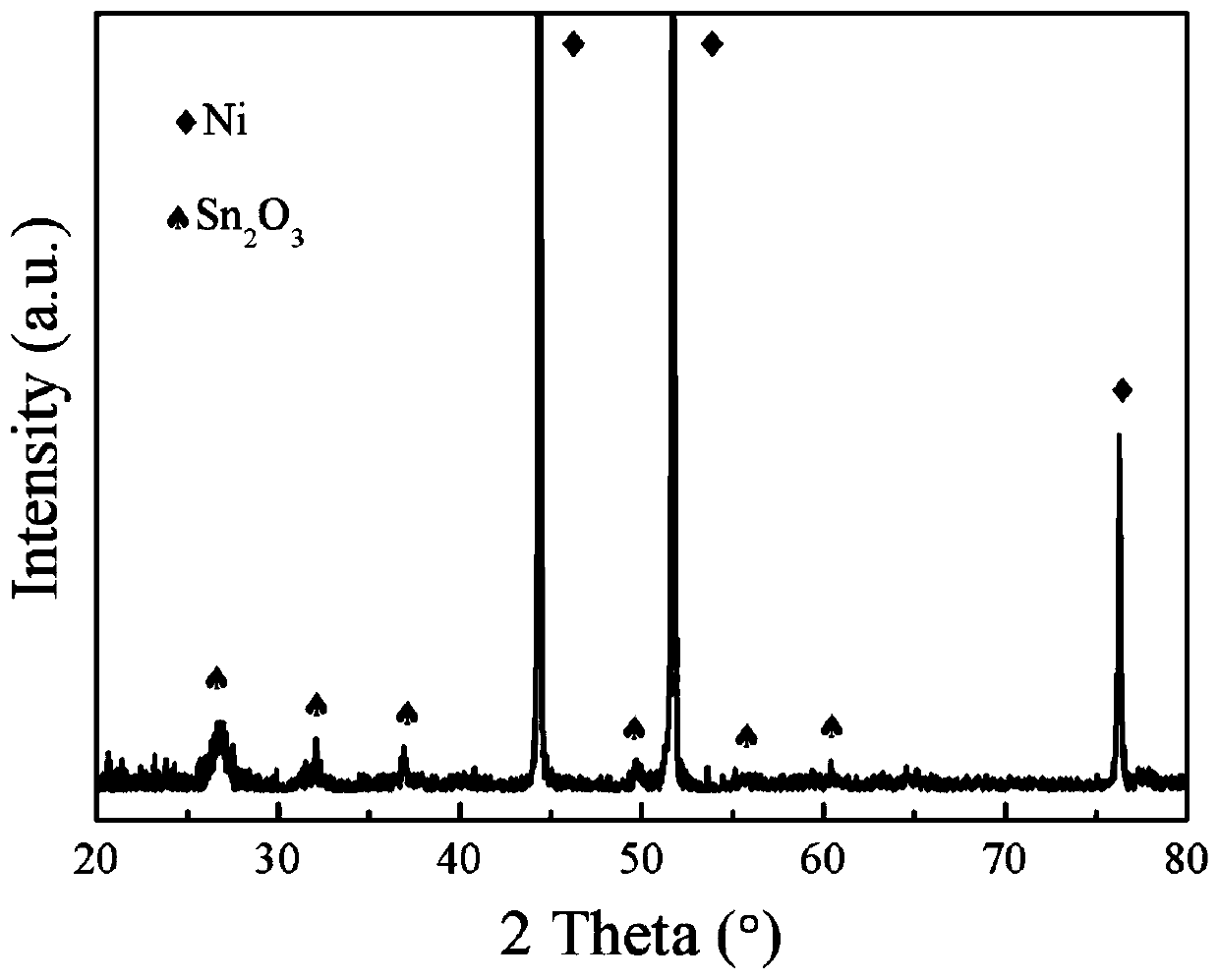

[0043] Example 1: First, put 40 mL of deionized water in a beaker, then dissolve 3.61 g of stannous chloride dihydrate and 5.88 g of trisodium citrate in it, and magnetically stir for 40 min to obtain a uniform and stable white thick suspension. Then, slowly add absolute ethanol into the beaker according to the volume ratio of absolute ethanol: deionized water 1:1, and continue stirring for 60 min to obtain a milky white turbid liquid precursor, which is for later use. The precursor solution was transferred to a 100 mL high-pressure stainless steel reactor, and the clean nickel foam sheet was horizontally fixed on the bottom of the reactor. Then, after the sealing and assembly of the reaction kettle was completed, it was placed in an oven for 18 hours at 190°C. After naturally cooling to room temperature, the reactor was opened, and the nickel foam sample was taken out, rinsed three times with deionized water, and kept in an oven at 100 °C for 12 h to obtain the canopy anoxic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com